- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

3390*1400*2140mm

-

Weight:

-

2800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customers' Requirements

-

After-sales Service:

-

Online support

-

Certification:

-

ISO CE

Quick Details

-

Production Capacity:

-

100t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huahong

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

3390*1400*2140mm

-

Weight:

-

2800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customers' Requirements

-

After-sales Service:

-

Online support

-

Certification:

-

ISO CE

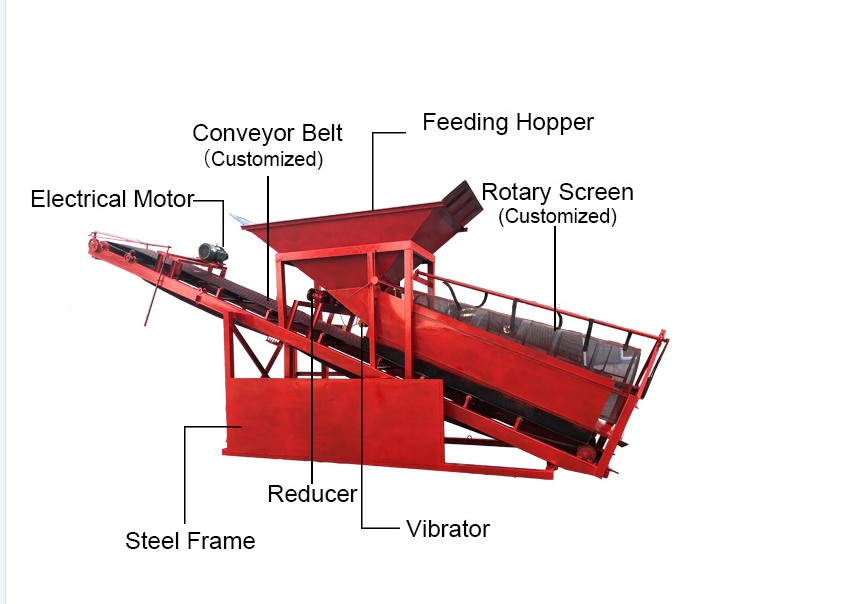

Product Description

Introduction

High Quality Industrial Compost Drum Sieve is essential units which can apply in the mineral and solid-waste processing industries. It consists of a perforated cylindrical drum which is normally elevated at an angel at the feed end. Physical size separation is achieved as the feed material spirals down the rotating drum, where the undersized material smaller than the screen apertures passes through the screen, while the over sized material exits at the other end of the drum.

1. Functions: configured for classification, screening, grading

2. Type: open type, closed type

3. Classification: shaft rotary screen, shaft less rotary screen

4. Construction: carbon steel, stainless steel

5.Applications Scope: widely used in chemical, coal, construction, gold mine, plastic,quarry,recycling, metallurgy, mineral-selecting industries, etc.

Features

1 The screen holeis not easy jamed.

2 smoothly operation and low noise.

3 simple structure and easy maintenance.

4 the screening tube can be closed, easy to collect dust airtight.

5 the high reliability and one-time investment is less.

6 high screening efficiency, long service life

High Quality Industrial Compost Drum Sieve is essential units which can apply in the mineral and solid-waste processing industries. It consists of a perforated cylindrical drum which is normally elevated at an angel at the feed end. Physical size separation is achieved as the feed material spirals down the rotating drum, where the undersized material smaller than the screen apertures passes through the screen, while the over sized material exits at the other end of the drum.

1. Functions: configured for classification, screening, grading

2. Type: open type, closed type

3. Classification: shaft rotary screen, shaft less rotary screen

4. Construction: carbon steel, stainless steel

5.Applications Scope: widely used in chemical, coal, construction, gold mine, plastic,quarry,recycling, metallurgy, mineral-selecting industries, etc.

Features

1 The screen holeis not easy jamed.

2 smoothly operation and low noise.

3 simple structure and easy maintenance.

4 the screening tube can be closed, easy to collect dust airtight.

5 the high reliability and one-time investment is less.

6 high screening efficiency, long service life

|

Model

|

Capacity

|

Power

|

Screen Diameter

|

Screen length

|

Dimension(LXWXH)

|

Weight

|

|

|

(t/h)

|

(kw)

|

(mm)

|

(mm)

|

(mm)

|

(kg)

|

|

GTS1015

|

50

|

3

|

1000

|

1500

|

2600*1400*1700

|

2200

|

|

GTS1020

|

100

|

4

|

1000

|

2000

|

3390*1400*2140

|

2800

|

|

GTS1225

|

160

|

5.5

|

1200

|

2500

|

4146*1900*2820

|

4200

|

|

GTS1530

|

250

|

7.5

|

1500

|

3000

|

4460*1900*2820

|

5100

|

|

GTS1545

|

350

|

11

|

1500

|

4500

|

5960*1900*2820

|

6000

|

|

GTS1848

|

450

|

15

|

1800

|

4800

|

6500*2350*4000

|

7500

|

|

GTS2055

|

600

|

30

|

2000

|

5500

|

7500*2550*4800

|

9600

|

|

GTS2265

|

800

|

55

|

2200

|

6500

|

8500*2750*5000

|

12800

|

Packing & Delivery

Certifications

CE & ISO

Our Service

1.We provide you with the prophase plan, process flow design and manufacturer

equipment according to your special demand.

2.Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you.

3.We provide one-year warranty to make sure your machine runs consistently.

repair main parts under right using for free in two years.

Welcome to visit our factory anytime !!!

We will be very happy to provide our best prooduct and professional service for you! Thank you!

equipment according to your special demand.

2.Send technicians to the jobsite for guiding the installation and adjustment,

training operators and finishing the check and accept together with you.

3.We provide one-year warranty to make sure your machine runs consistently.

repair main parts under right using for free in two years.

Welcome to visit our factory anytime !!!

We will be very happy to provide our best prooduct and professional service for you! Thank you!

Contact me

Hot Searches