- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UTron

-

Model Number:

-

UTron202005220000000000000007

-

Application:

-

Cooling Tower Scale Removing

-

Technique:

-

Sand blasting, Acid washing and Brush Coating

-

Grade:

-

Grade 1 Pure Titanium

-

Shape:

-

Mesh tube

-

Coating:

-

Ru-Ir Ir-Ta Pt

-

Coating Thickness:

-

8~20 Micron

-

Operating life:

-

3-5 years

-

Function:

-

Anti scale and rust, Kill bacterial,algae

-

Principle:

-

Electrolysis water molecules

-

Warranty:

-

1 year

-

MOQ:

-

1 Set

-

Sample:

-

Avaliable

-

Certificate:

-

ISO 9001:2008

Quick Details

-

Powder Or Not:

-

Not Powder

-

Ti Content (%):

-

99.99%

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

UTron

-

Model Number:

-

UTron202005220000000000000007

-

Application:

-

Cooling Tower Scale Removing

-

Technique:

-

Sand blasting, Acid washing and Brush Coating

-

Grade:

-

Grade 1 Pure Titanium

-

Shape:

-

Mesh tube

-

Coating:

-

Ru-Ir Ir-Ta Pt

-

Coating Thickness:

-

8~20 Micron

-

Operating life:

-

3-5 years

-

Function:

-

Anti scale and rust, Kill bacterial,algae

-

Principle:

-

Electrolysis water molecules

-

Warranty:

-

1 year

-

MOQ:

-

1 Set

-

Sample:

-

Avaliable

-

Certificate:

-

ISO 9001:2008

How does water scale harmful to equipment?

Water scale mainly consists of carbonate, magnesium, occupy 60%. Other kind scale includes sulfate, silicate, iron, occupy around 10%. Dust sludge around 30%. Scale largely reduce heat-exchange and reaction efficiency, which largely increase power consumption. Take center air-conditioning as example. Once scale 0.3mm forms at heat ex changer will cause 20% heat loss, increase 10% energy consumption.

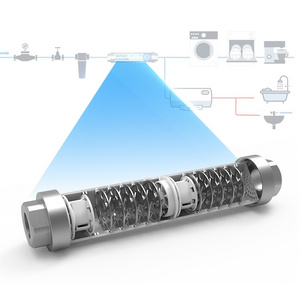

Working Principle:

|

Feature:

1.Save Energy, Protect Environment

Electrical descaler can works under high efficiency, low power consumption. As of its constant working, which ensure constant electrolysis environment. It reduces over 4% power consumption. Easy to clean, no need drain,friendly to environment.

2.Low Cost Maintenance

3. Long lifetime

Electrical descaler can separated chemical corrosion, long its lifetime.

4. Easy Operation

Clean dirty collector 2-3times.

After using 2months, water can achieve best condition. Even if stop using for one moth, recycling water systemwon’t appear stop working or alarm.

Descaling effect:

Packaging & Delivery

Packaging Details:

1. Inside: Kraft papers, plastic bags, polyethylene foamed sheet;

2. Outside: packing: wooden box;

3. Or according to customer requirement.

Packing Picture Example:

Port:

Tianjin, Shanghai, Qingdao or any other Chinese main port.

Lead Time:

2-15 days after payment confirmed.

Customize the Titanium Electrodes:

Utron has a professional technical team with decades of experience on titanium electrodes, coated titanium anodes; we can design the coating according to your specific working condition. Customize the operating life as per clients’ specific needs.

Develop New Products:

UTron has excellent innovative technical engineers help you to develop new products.

Consulting and Technical Assistance:

The sales engineers and technical engineers in UTron are professional; they have intrinsic knowledge of the world of cathodic protection, waste water treatment, electroplating and electrowinning. Feel free to contact them you have any queries. They are committed to improve your processes or to solve a tricky challenge that, given certain circumstances, might have never previously existed.

OEM:

UTron can produce as per clients’needs.

Tests:

UTron can provide the Accelerated Life Test, Coating X-Ray Test, Coating Thickness Test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

Samples:

UTron can offer free or paid samples for test.