- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

standard or customized size

-

Product name:

-

Rubber o ring

-

Size:

-

standard or customized size

-

Material:

-

NBR EPDM SIL HNBR FKM CR NR VAMAC

-

Hardness:

-

40-90 Shore

-

Color:

-

any color

-

Application:

-

sealing

-

Advantage:

-

ready-made

-

Packing:

-

PE Bag+Carton

-

Delivery time:

-

3-5days

-

Certification:

-

ROHS2.0 REACH food grade CP65

Quick Details

-

Processing Service:

-

Moulding, vulcanization

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZZH

-

Model Number:

-

standard or customized size

-

Product name:

-

Rubber o ring

-

Size:

-

standard or customized size

-

Material:

-

NBR EPDM SIL HNBR FKM CR NR VAMAC

-

Hardness:

-

40-90 Shore

-

Color:

-

any color

-

Application:

-

sealing

-

Advantage:

-

ready-made

-

Packing:

-

PE Bag+Carton

-

Delivery time:

-

3-5days

-

Certification:

-

ROHS2.0 REACH food grade CP65

Heat resistant ASTM D2000 BG714 buna-N NBR nitrile 70 SH-A black rubber o ring sealing ring for lighter

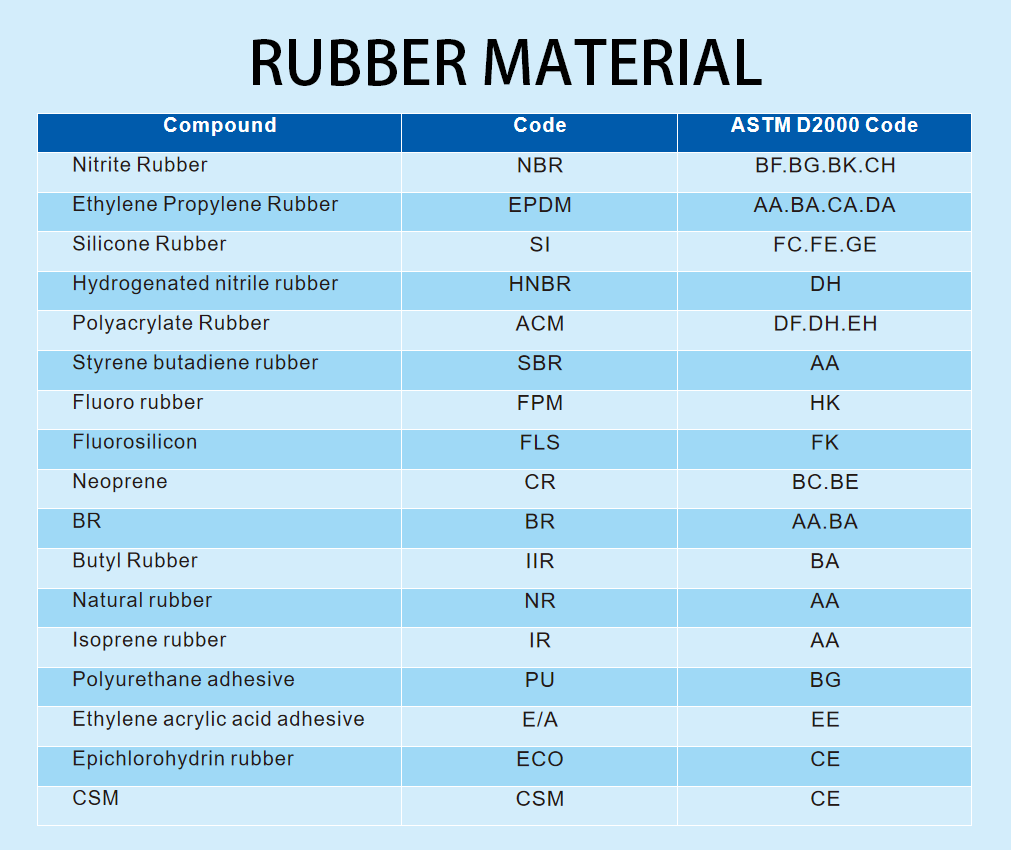

| Standard ASTM D1413 | NBR | ||||

| Chemical Name | Nitrile Rubber (Buna) | ||||

| Properties | The Acryl-nitrile(ACN)content vanes In technical products (18 to 50%). The higher the ACN content the better is the oil and fuel resistance. When the ACN content is higher, low temperature resistance, elasticity, and the compression set are adversely affected. NBR has good mechanical properties when compared with other elastomers and a particularly high wear resistance | ||||

| Working Temp.℃ | Normal Formulation ℃ | -35~110℃ | |||

| Specified Formulation ℃ | -50~150℃ | ||||

| Hardness | SH-A 40-90 | ||||

| Color | Per request | ||||

| ASTM D2000 Class | BF BG BK CH | ||||

| ASTM D2000 SPEC. | ASTM D2000 M2BG714 A14 B14 EA14 EF11 EF21 EO14 EO34 | ||||

| Specified Property. | Low Temp., Food grade, Ozen Resistance, Low Compression set, Self-lubricating etc. | ||||

| Other material or special property required, please contact with us for more information…… | |||||

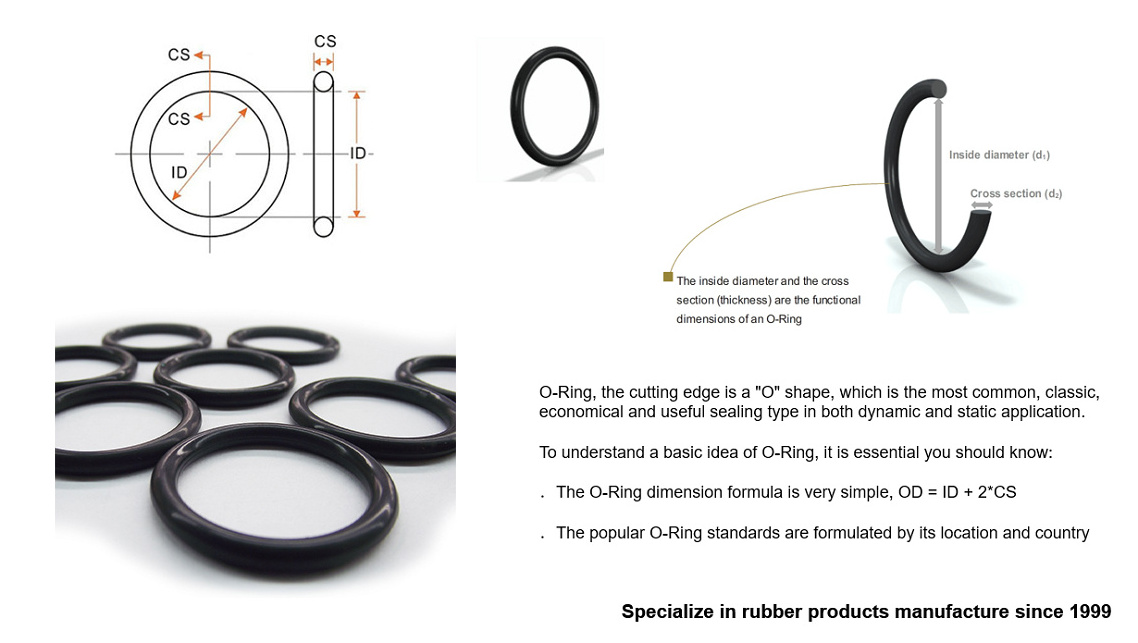

Which O-Ring Material Is Right for Me?

When you’re choosing an O-ring for your project, it’s important to keep in mind the different factors that will affect the O-ring material. These factors include:

The application of the O-ring

The pressure the O-ring will be under

The temperature the O-ring will be subjected to

The size of the fastener

The medium being sealed

Each of these factors will have an impact on how the O-ring performs. Not all O-ring materials are effective in every environment, and what works during one application may not work in another.

Silicone rubber O-rings are the most popular material choice because they’re capable of performing in a wide range of temperatures without melting or hardening. However, silicone rubber does have its limits. The average temperature range for silicone rubber O-rings is between -62 and 204 degrees Celsius. Other O-ring materials such as Nitrile and fluorosilicone are versatile as well, but have shorter temperature ranges.

Not sure which O-ring material is the right fit? We’ve got you covered. Contact us at us today to get a professional opinion on the right O-rings for you. We’ll be more than happy to answer any questions you may have.

| Size range | |

| ID (Inner Dia.) | From 0.50mm to 1500mm |

| CS (Cross Section) | From 0.50mm to 30mm |

Application for the o-ring

Rubber is a type of thermosetting elastomer with viscoelasticity that other materials do not have. According to the material source, it can be grouped into two categories: natural rubber and synthetic rubber. There are many types of synthetic rubber, and depending on the type of monomers and polymerization methods, synthetic rubber can be formulated to achieve the desired physical strength and chemical resistance, and is widely used in various industries. The correct selection of materials and good compound design are very important.

Material development is critical to product performance.

Usually, there is no standard compound that can meet the requirements of different application environments. Material development is critical to product performance. Material advancement has always been the focus of our Research and Development, and our laboratory is equipped with a range of testing capabilities managed by our team of R&D engineers.

Compound design and Development

Our approach to material development and compound design is customer driven, and our many years of experience help our customers gain a competitive advantage in their field of operation.

With many years of established relationships with leading raw material suppliers, we are in a position to customize material development to meet your specific requirements.

The three key considerations in rubber compound design are cost control, specification requirements and product manufacturing process. Optimization seeks to reduce cost or improve productivity, and this can be achieved through the proper use of additives. Additives include carbon black or silica fillers, plasticizers, vulcanizing agents, accelerators, protective agents (eg: antiozonants), processing aids and so on. The proper use of these additives will affect the performance and durability of the finished product.

Laboratory Testing Capabilities

Our laboratory can carry out ranging of testing such as: Heat aged test. Oil Imersion test. Compression set test ect. to ensure that the materials can meet customer specifications. If necessary, we can conduct multiple batch tests and recommend specifications.

we have a powerful database system. All test results will be included in the database system and archived to help R&D personnel improve materials and control quality.

On the way to "excellance" since our company was founded in 1999, we always keep moving forward, we sincerely appreciate all your comments and suggestions.

Specialize in rubber products manufacture since 1999 :

O-Ring (AS 568, DIN3771, Metric, GB/T 3452.1, JIS B2401, ISO3601), X-Ring, D-Ring, Y-Ring, V-Ring, Square Ring, Washer, Grommet, Diaphragm, Rubber bonded parts(metal,plastic,mesh), Hydraulic seals, Medical rubber components, Condutcive Silicone tips, Vacuum suction cups, Telflon coating rubber components, Rubber parts for Sanitary &Air &Oil &Drinking water system, OEM and other custom molding rubber products.

What value can ZZH offer?

1. All products are manufactured in our own factory to ensure a consistently high quality.

2. Accurate tool house technology to create tools for high quality production.

3. Best lead time could be 1-2 weeks which to decrease the waiting of long lead time.

4. 20 years rich Experienced engineers work with you to solve problems.

5. Suitable and well known raw material suppliers to guarantee the products basic quality

6. Certificated compound to meet specific markets.

7. Certificated laboratory (Cooperative suppliers)to develop and identify match compound per your specification or ASTM D2000 call out.

8. Wide range of O-Ring hardness from 20 to 90 duro.

9. Various international O-Ring standards, most sizes are ready-made tooling which you don't need to invest.

10. External Lubricants & Coatings on O-Ring surface for your assembly (PTFE coating, Silicone fluid,).

11. Well O-Ring surface especially in parting line.

12. provide strict production control in CPK/PPK in specific products.

13. Have worked with Flex.,Midea, JUUL for many yeas.