- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/440V

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

Copper Ore Beneficiation Plant

-

Color:

-

Customers' Requirements

-

Application:

-

Flotation Process Plant

-

After Sale Service:

-

Engineer Overseas Service

-

Price:

-

Competetive (Can Negotiate)

-

Factory:

-

50,000 Square Meters Closed Workshops

-

Installation and Trial:

-

We Can Send Engineer for Guidance

-

Capacity:

-

10-500t/h

-

Certification:

-

ISO9001 CE, ISO9001:14000

-

Main products:

-

ball mill, flotation machine, jaw crusher

Quick Details

-

Production Capacity:

-

10-500t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMJO

-

Voltage:

-

220/380/440V

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

Copper Ore Beneficiation Plant

-

Color:

-

Customers' Requirements

-

Application:

-

Flotation Process Plant

-

After Sale Service:

-

Engineer Overseas Service

-

Price:

-

Competetive (Can Negotiate)

-

Factory:

-

50,000 Square Meters Closed Workshops

-

Installation and Trial:

-

We Can Send Engineer for Guidance

-

Capacity:

-

10-500t/h

-

Certification:

-

ISO9001 CE, ISO9001:14000

-

Main products:

-

ball mill, flotation machine, jaw crusher

Product Description

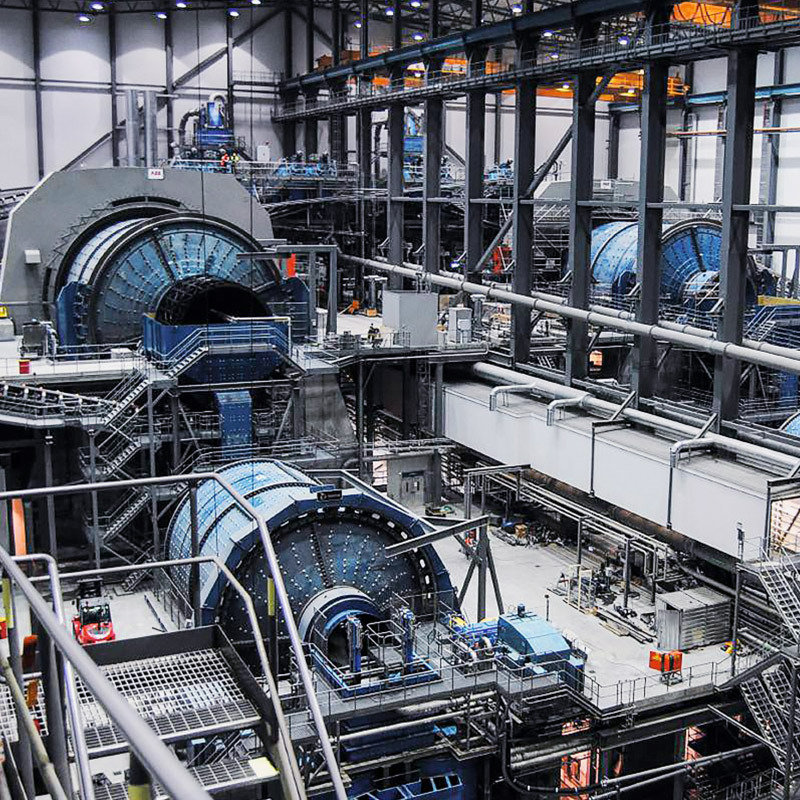

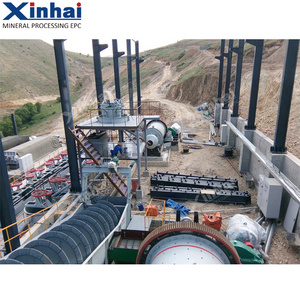

1000Tpd Gold Copper Ore Flotation Concentrator Beneficiation Machine Mine Gold Copper Ore Flotation Machine

Copper ore beneficiation production line is one of the important processes applied, and it is even more widely used. According to statistics,

more than 90% of copper minerals with copper are treated by flotation process

.

The production line has the advantages of high yield, low energy, high processing capacity and reasonable economy.

Copper ore refers to a collection of natural minerals that can be used to extract copper. More than 280 copper-bearing minerals have been discovered, but only 16 of them are major.

The major mined ores include chalcopyrite (a compound composed of copper, sulfur, and iron), chalcopyrite, and porphyry.

Copper ores usually consist of copper sulfides or oxides mixed with other minerals that, when reacted with sulfuric acid, produce blue-green copper sulfate.

Copper ore beneficiation equipment production line scope of application:Weak magnetic mineral beneficiation, such as hematite, brown iron ore, ilmenite, wolframite, tantalum niobium ore, etc.. Non-metallic minerals in addition to iron purification, such as should be time, feldspar, nepheline, fluorite, silica, lithium fai, kaolin, etc..

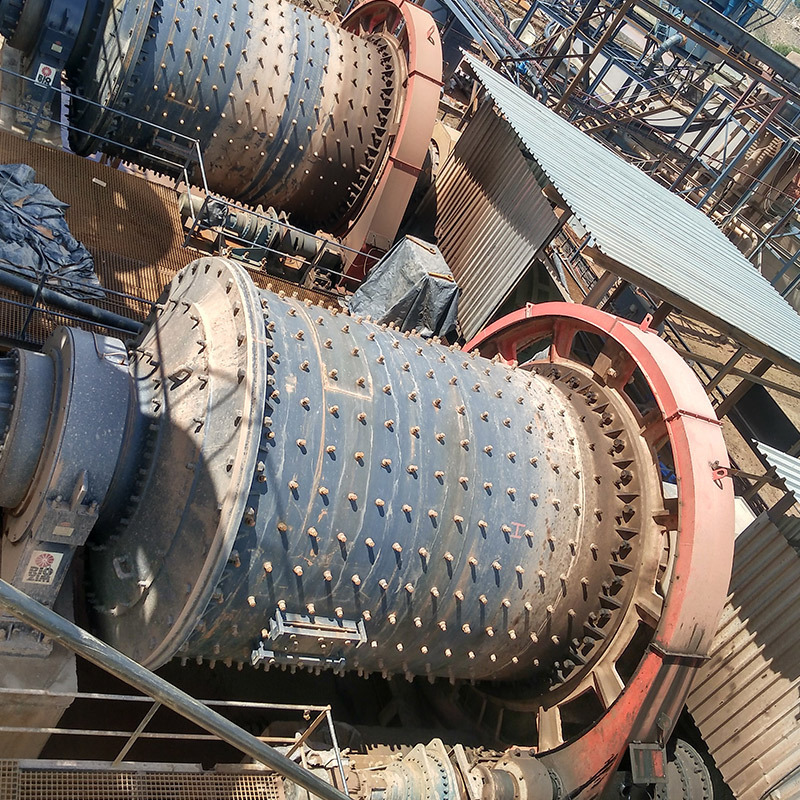

The beneficiation of copper ore generally adopts a relatively simple process.

Firstly, a section of rough grinding, so that the particle size of -200 mesh about 50% -70%, and then a roughing, 2-3 times selection and 1-2 times sweeping. If the copper mineral size is fine, we can consider using the stage grinding process.

Most of the processing plant to deal with porphyry copper ore, the use of coarse concentrate regrinding - selection of stage grinding process, the first coarse grinding, roughing, sweeping, the coarse concentrate and then fine grinding and fine selection, in order to obtain high-grade copper concentrate and sulfur concentrate. Coarse grinding makes -200 mesh about 45-50%, fine grinding makes -200 mesh about 90-95%.

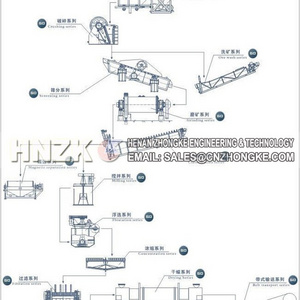

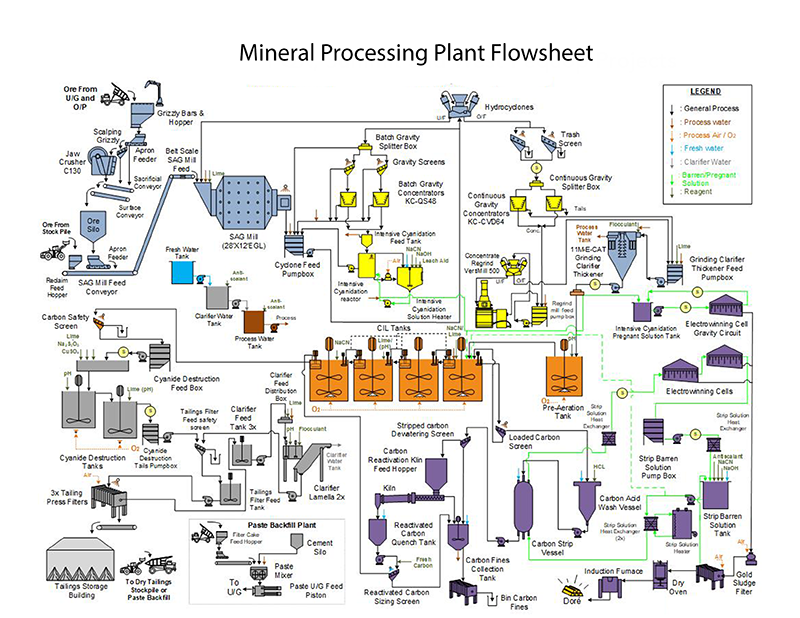

Working Flow

The mined ore is firstly crushed by the

jaw crushe

r

, and then fed into the wet

ball mill

for fine crushing through the feeder. After ball milling, the ore slurry enters the

spiral classifier

for classification. After classification, the ore slurry enters into

flotation machine

, and according to the nature of different minerals, different chemicals are added to flotation, and the copper ore is separated out. The copper concentrate with high water content is concentrated in

the concentrator

and then dried in

the dryer

to get dry copper concentrate powder.

The significant advantages of ZOOMJO copper ore beneficiation plant include:

1. Excellent beneficiation effect, which can significantly improve the grade of copper concentrate.

2. Rational layout of the production line, high copper recovery rate, ensuring full utilization of resources.

3. Very little harmful gases and odors emitted by the chemicals, which is conducive to environmental protection and employee health.

4. We customize solutions for our customers, thus improving production efficiency and meeting their specific needs.

Main Equipment

The complete set of copper ore beneficiation equipment production line is

mainly composed of copper ore beneficiation equipment such as crusher (including coarse crushing and fine crushing), grinder, classifier, thickener, flotation machine, dryer and so on.

Jaw Crusher

Spiral Classifier

Shaking Table

Ball Mill

Flotation Machine

Magnetic Separator

According to the different composition of copper ore, choose the appropriate copper ore beneficiation production line technology and copper ore beneficiation equipment.

ZOOMJO MINING MACHINERY offers a wide range of solutions for beneficiation of gold, silver, copper, iron, zinc, chromium, molybdenum, feldspar, manganese ore and many more other ore materials.

We can provide advanced beneficiation technology, beneficiation plant design, equipment fabrication and installation guidance on a turnkey basis!

Technical Parameter

The specific configuration of mineral processing equipment should be designed according to the nature of the ore and the corresponding optimal process. Different physical and chemical properties of different ores are different, need to use different beneficiation technology and equipment in order to achieve the best beneficiation effect.

|

Product name

|

Specification

|

Quantity

|

Power

(kW) |

Note

|

||

|

Trough feeder

|

980×1240

|

1

|

7.5

|

|

||

|

Jaw crusher

|

PE400×600

|

1

|

30

|

Cast steel rack

|

||

|

Fine jaw crusher

|

PEX150×750

|

1

|

15

|

Cast steel rack

|

||

|

Tilting feeder

|

400×400

|

1

|

2.2

|

|

||

|

Ball mill

|

GZM1.83×3.6

|

1

|

155

|

|

||

|

Classifier

|

FLG-1200

|

1

|

7.5

|

|

||

|

Mixing barrel

|

1500×1500

|

1

|

3

|

|

||

|

Mixing barrel

|

1500×1800

|

1

|

11

|

|

||

|

Flotation Machine

|

5A

|

36

|

5.5/tank

|

|

||

|

Belt conveyor

|

TD75,B=500,the number and length of transport belts are determined according to the actual situation at the site

|

|

|

|

||

When we design beneficiation solutions for our customers, we will first analyze the ore samples in detail and recommend the optimal equipment and process routes according to the test results, so as to achieve the goals of high recovery and high efficiency. We will provide customized beneficiation solutions for each customer according to the ore.

Our Advantages

EPCM all-inclusive service

ZOOMJO not only focuses on the manufacturing of mining equipment, but also provides a full range of services from engineering consulting, beneficiation test and research, to equipment manufacturing, installation and commissioning, personnel training, long-term tracking service and plant management and operation, so as to enable customers to realize one-stop solutions, shorten the construction period, and realize the benefits earlier.

High quality mining equipment

ZOOMJO in the production of equipment, from procurement to quality control process strictly control, to ensure that the raw materials are flawless. At the same time, each product is fully inspected and pre-acceptance, and debugging, to eliminate quality problems.

Shipping and Transportation

The equipment will be shipped in time after completion of manufacture. If the contract requires guided installation or contracted installation, after the site has the installation conditions, the company will quickly send staff on-site operation, and establish customer files, provide permanent tracking service to ensure long-term normal operation of the project to avoid customer losses. At the same time, we provide one year warranty for the whole machine, if there is any problem, you can contact us to deal with it.

About after-sales service

ZOOMJO after-sales service team consists of 50 experienced technicians, including old experts and senior technicians with more than 20 years of mining experience. We promise to arrive at the scene within 24 hours at home and 48 hours abroad (excluding passport time) to solve the problem quickly, which will greatly shorten the production downtime and reduce the loss of customers.

Customer Cases

ZOOMJO's mining process equipment, including high efficiency concentrator, crusher, ball mill, agitator tank, flotation machine, screening equipment, drying equipment, etc., have been successfully sold to more than 160 countries around the world, covering South Africa, Tanzania, Nigeria, Ethiopia, Kenya, Egypt, Zambia, Uganda, Ghana, India, Indonesia, Singapore, Australia and other countries.

Packaging & Shipping

Packaging Details:

We will make different packaging according to different machine sizes. Standard international export packing, container, wooden box.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Hot Searches