- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/50hz

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

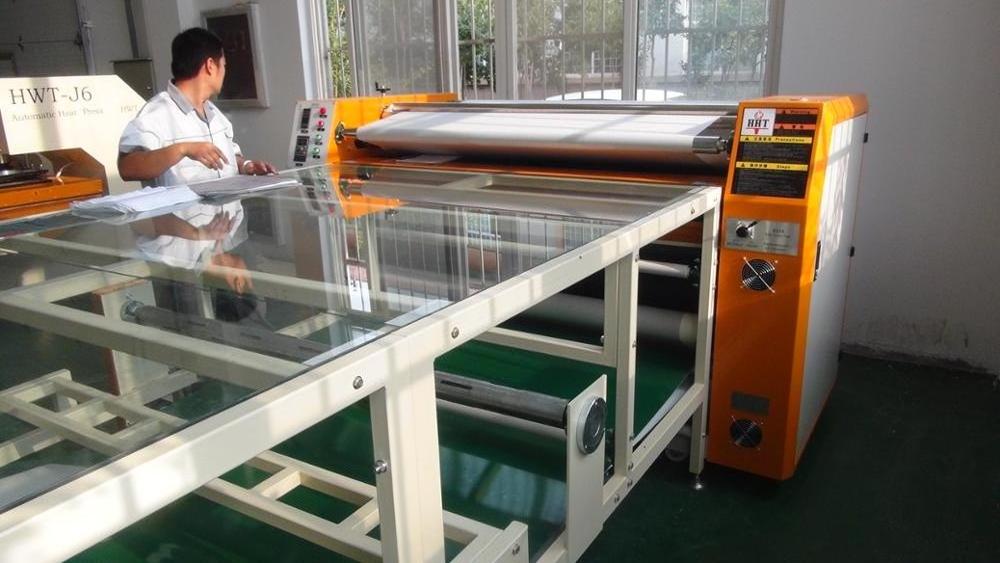

Textile Calender Machine-Calender for Sublimations-Fabric Calender

-

Heating:

-

Oil-based heating pipe

-

Drum Diameter:

-

600mm

-

Power:

-

43kw

-

Blanket width:

-

1730mm

-

Max working speed:

-

210-230m/h

-

Working Table Area:

-

3000*1780mm

-

After-sales Service:

-

Engineers available to service overseas

-

Application:

-

shirts and cloth printing

-

Power supply:

-

220V50HZ(1phase 2wire)/380V50HZ(3phase 4wire)

-

Certification:

-

ISO

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Flatbed Printer

-

Color & Page:

-

Multicolor

-

Voltage:

-

380v/50hz

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

Textile Calender Machine-Calender for Sublimations-Fabric Calender

-

Heating:

-

Oil-based heating pipe

-

Drum Diameter:

-

600mm

-

Power:

-

43kw

-

Blanket width:

-

1730mm

-

Max working speed:

-

210-230m/h

-

Working Table Area:

-

3000*1780mm

-

After-sales Service:

-

Engineers available to service overseas

-

Application:

-

shirts and cloth printing

-

Power supply:

-

220V50HZ(1phase 2wire)/380V50HZ(3phase 4wire)

-

Certification:

-

ISO

Hot small heat press transfer roll fabric printing textile roll to piece digital sublimation rotary calender machine

is a multi-functional machine which is designed especially for both roll to roll transfer printing and cut pieces transfer printing,and it is also applicable for pure cotton transfer printing in warm temperature.

Character:

1. HJD-J9 type roller transfer printing machine adopts new design concept,Has three closed three enter function (three enter: into cloth, transfer printing paper, paper into protection. Three closed: after the transfer of color paper, taking protection of paper and cloth) uses the aspirant type structure. Suitable for transfer printing with horses, fabrics and clothing, fully functional, stable quality. Widely used in clothing production, umbrellas, crafts, decoration materials heat transfer sublimation printing, is a professional printing factory, advertising company first heat transfer sublimation printing equipment.

2. Heat pipes adopts stainless steel imported from Taiwan, heating tube all immerse in the thermal oil heating heating, heating up fast, save electricity saving energy more than 15%.

3. Heating roller surface by the teflon treatment and anti-sticking (prevent thrum wire tail glue roller), durable. Roller temperature is more stable and ensure that each point on the surface of temperature, heat transfer without off color.

4. Choose the United States dupont material blanket, transfer printing effect is good, long service life.

5. Pneumatic pressure device, according to different materials to adjust, transfer speed is faster, more vivid colors.

6. High hardware configuration and the felt not deviate. The main panel and all the shaft roller reinforcement and professional seiko production

7. Belt used Separate type, using synchronous adjustment, and with a pressure balance beam, ensure each blanket with consistent and heating cylinder pressure, completely solve the mat with cooling problem, in the event of blackouts during the shutdown or blanket with better protection, prolong its service life.

8. Oil with independent machine box, add heat conduction oil more convenient. Has the distinct advantage of the explosion-proof, safety performance is high

9. The use of frequency conversion governor, are free to adjust the printing speed, more stable transfer speed.

10. The machine can according to customer needs, set automatic idle time and regular shutdown function, for the operator to save time.