- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

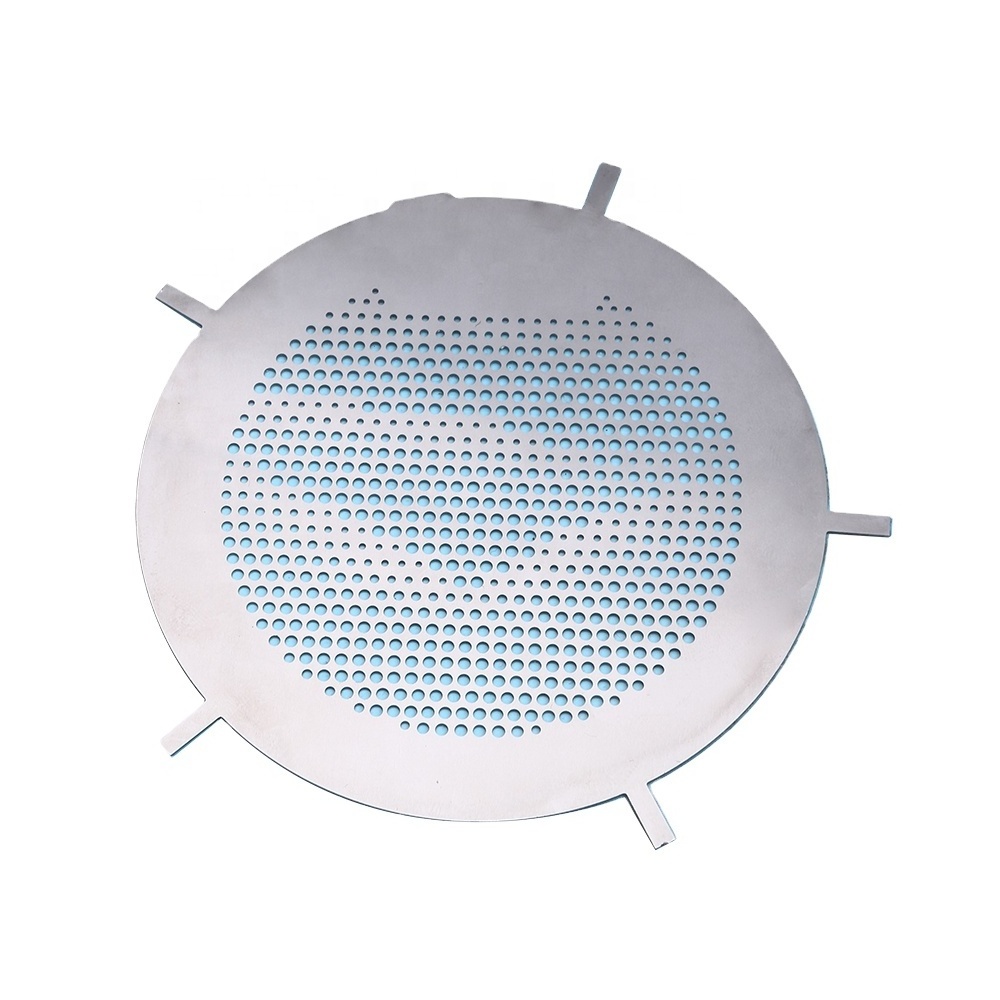

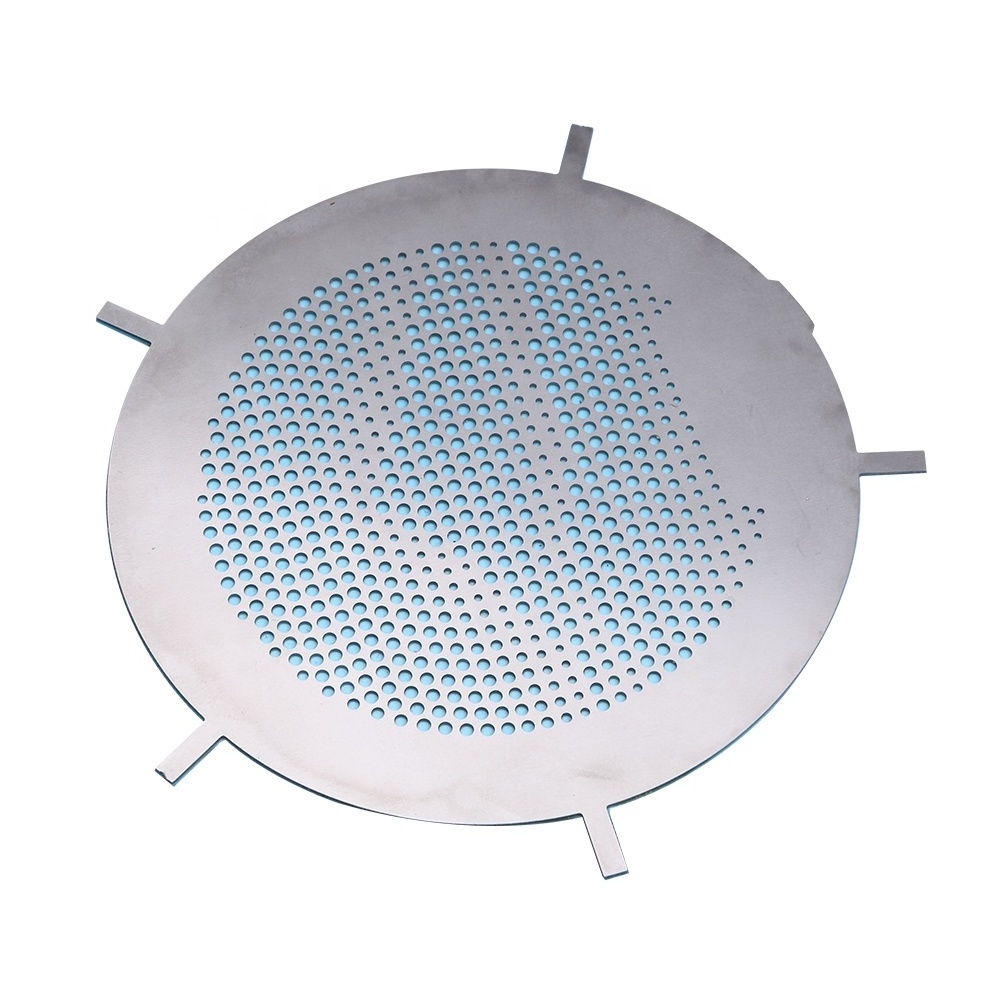

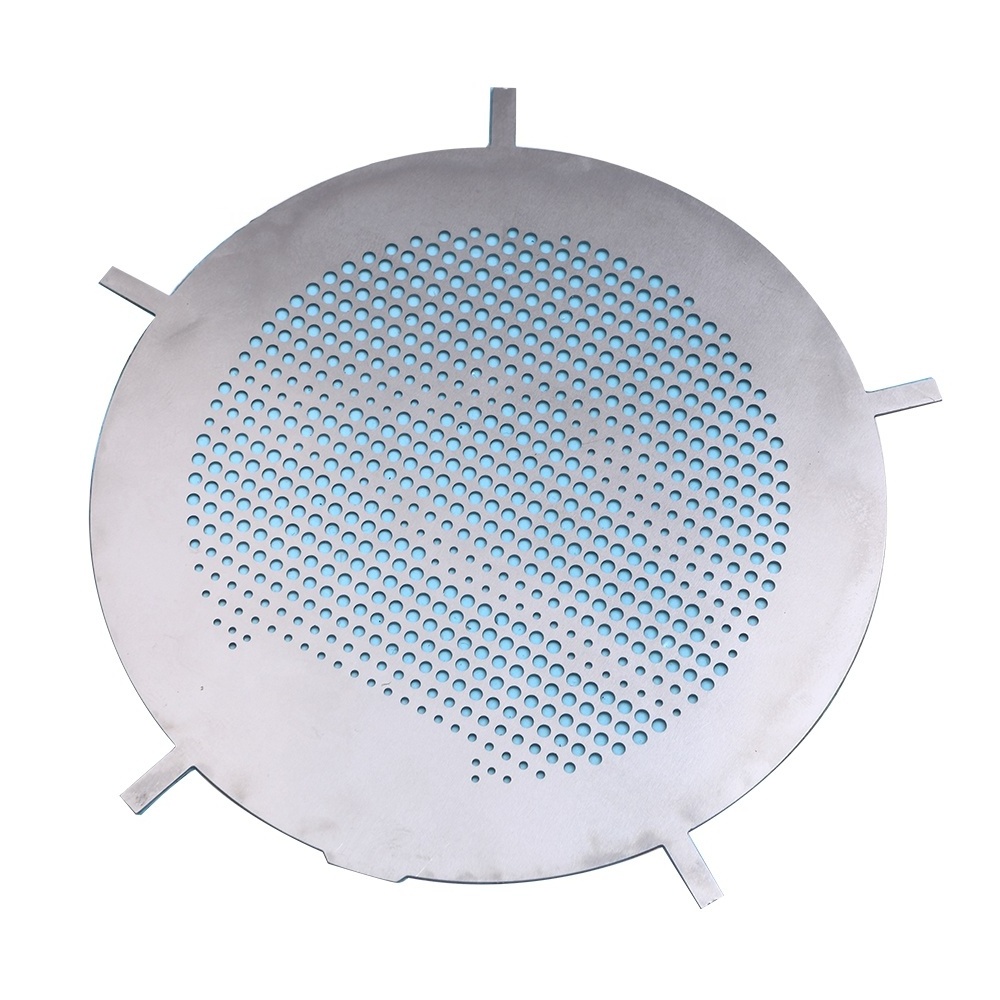

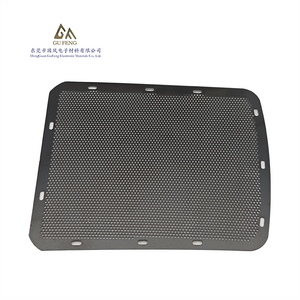

Speaker grill

-

Brand Name:

-

YM

-

Product name:

-

YM-speaker grill

-

Material:

-

Metal or customized

-

Usage:

-

Car Speaker

-

Color:

-

Customized Color

-

Size:

-

Customers' Requests

-

Application:

-

Wireless Speaker,car speaker

-

MOQ:

-

1000pcs

-

Design:

-

Custom design

-

Feature:

-

Corrosion Resistance

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Speaker grill

-

Brand Name:

-

YM

-

Product name:

-

YM-speaker grill

-

Material:

-

Metal or customized

-

Usage:

-

Car Speaker

-

Color:

-

Customized Color

-

Size:

-

Customers' Requests

-

Application:

-

Wireless Speaker,car speaker

-

MOQ:

-

1000pcs

-

Design:

-

Custom design

-

Feature:

-

Corrosion Resistance

Product Description

Specification

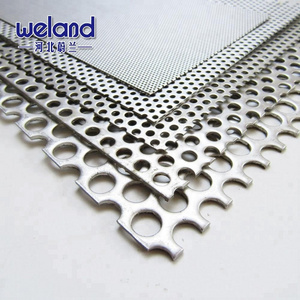

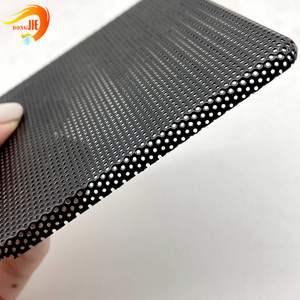

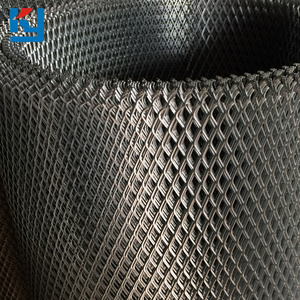

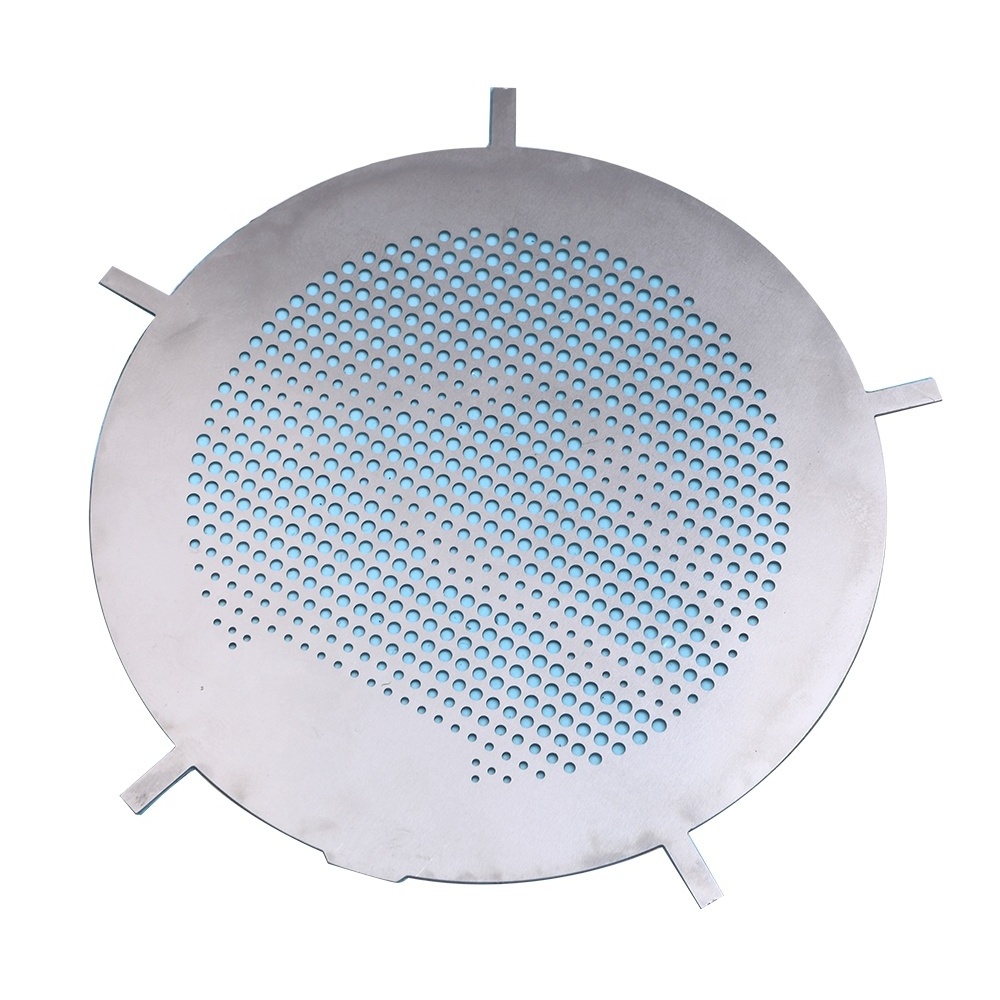

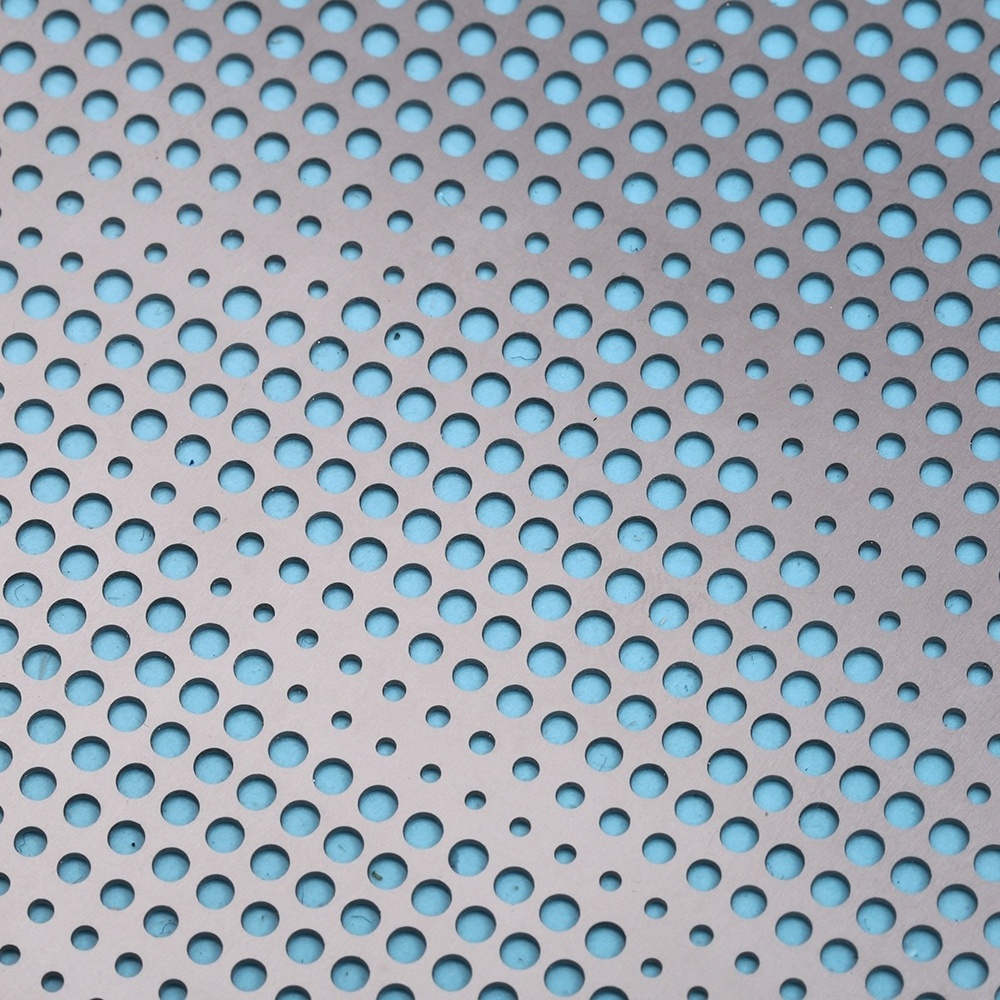

Photo-etching has been widely used in the manufacturing of car loudspeaker mesh grilles, many branding car manufacturers or loudspeaker manufacturer benefit from this technology, as it features:

1,Low tooling cost, no need for expensive DIE/Mould -- prototype normally costs only hundred dollars

2, Design flexibility -- Photo etching allows much flexibility on product design no matter it is product outer shape or the hole patterns, there is even no cost for complex designs.

3, Stress and burr free, smooth surface -- the material temper will not be affected during this process and it can guarantee a very smooth surface

4, Easy to coordinate with other manufacturing processes such as PVD plating, stamping, brushing, polishing and so on

5, Various material options -- stainless steel, copper, brass, aluminum, titanium, metal alloy at the thickness from 0.02mm to 2mm are all available.

Your competitors are using photo etching to supply better products now...Why not have a try?

1,Low tooling cost, no need for expensive DIE/Mould -- prototype normally costs only hundred dollars

2, Design flexibility -- Photo etching allows much flexibility on product design no matter it is product outer shape or the hole patterns, there is even no cost for complex designs.

3, Stress and burr free, smooth surface -- the material temper will not be affected during this process and it can guarantee a very smooth surface

4, Easy to coordinate with other manufacturing processes such as PVD plating, stamping, brushing, polishing and so on

5, Various material options -- stainless steel, copper, brass, aluminum, titanium, metal alloy at the thickness from 0.02mm to 2mm are all available.

Your competitors are using photo etching to supply better products now...Why not have a try?

|

Product name

|

Chemical Etched Stainless Steel Metal Speaker Cover Grill for Vehicle

|

|

Material

|

Stainless steel,aluminum,brass, copper, bronze, iron, precious metals or customize

|

|

Size

|

According to customers

|

|

Technique

|

High precision etching

|

|

Hole

|

0.01mm(customize)

|

|

Thickness

|

0.03-2mm is available

|

|

Hole shape

|

Hexagon, oval, round, rectangle, square, or customized

|

|

Surface finish

|

Clean .no burr

|

|

Application

|

Fiber filter,Textile machines,Car parts or customize

|

|

Certificate

|

RoHS,ISO

|

|

Inspection

|

Two-dimension inspection machine,magnifier

|

Packing & Delivery

Packing Details : Packing as customize.

Delivery Details :7-10days after order of etching parts

Delivery Details :7-10days after order of etching parts

Hot Searches