- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4080*925*1560

-

Power (kW):

-

5.1kw

-

Weight (KG):

-

600 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Color:

-

Customers Requirement

-

edge thickness:

-

10-55mm

-

edge width:

-

0.4-3mm

-

transport power:

-

0.75kw

-

glue post power:

-

0.55kw

-

fine-trimming motor power:

-

0.75kw*2

-

polishing motor power:

-

0.18kw*2

-

Work pressures:

-

0.7mpa

-

heater power:

-

1.5kw

-

polishing power:

-

0.18kw*2

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JINHAI

-

Voltage:

-

380 V(220V,400V,415V,440V etc)

-

Dimension(L*W*H):

-

4080*925*1560

-

Power (kW):

-

5.1kw

-

Weight (KG):

-

600 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Color:

-

Customers Requirement

-

edge thickness:

-

10-55mm

-

edge width:

-

0.4-3mm

-

transport power:

-

0.75kw

-

glue post power:

-

0.55kw

-

fine-trimming motor power:

-

0.75kw*2

-

polishing motor power:

-

0.18kw*2

-

Work pressures:

-

0.7mpa

-

heater power:

-

1.5kw

-

polishing power:

-

0.18kw*2

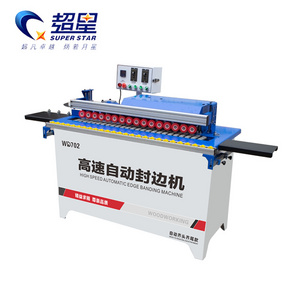

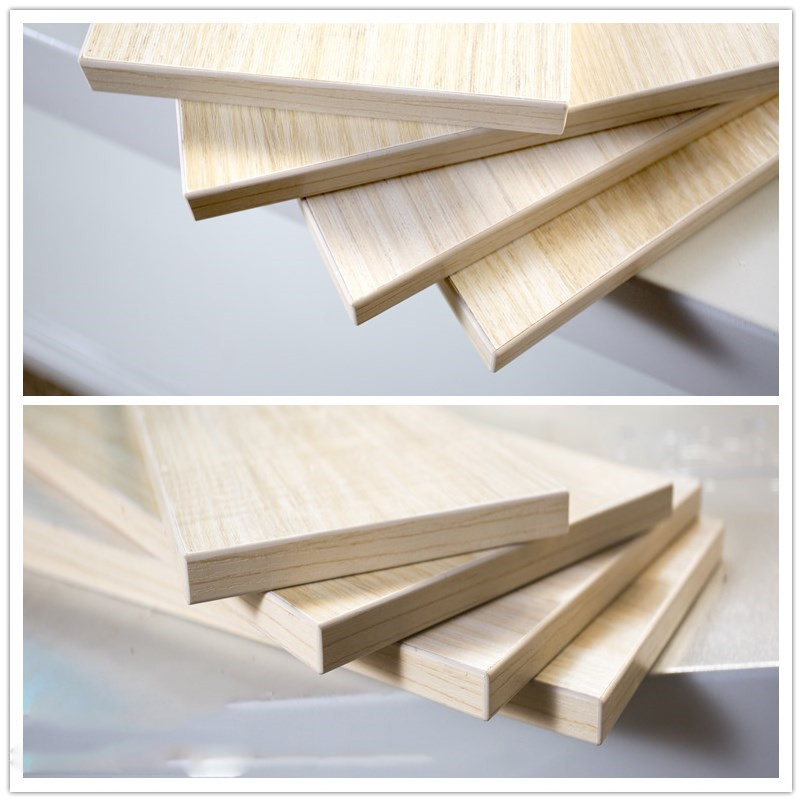

This edge banding machine is suitable for straight edge banding of solid wood board, fiberboard, particleboard and other board workpieces, the edge sealing material can be solid wood strip, PVC, melamine, veneer, etc. Imported motor and high quality electrical components.Product serialization and diversified customer selection. High precision and efficiency.

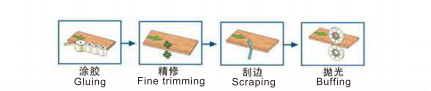

Display of usage effects:

| Model | JH-360B | |

| Edge width | 0.4-3mm | |

| Transport power | 1.5kw | |

| Glue post power | 0.55kw | |

| End-trimming motor power | 0.37kw*2 | |

| Fine-trimming motor power | 0.75kw*2 | |

| Polishing motor power | 0.18kw*2 | |

| Glue box heater | 1.5KW |

|

1.Multilingual screen We provide operation screens in multiple languages, supporting more than 50 languages including English, Spanish, Portuguese, French, Russian, etc. |

|

|

2. Gluing and press mechanism adopts glue melting device to gelatinize the plates and tape uniformly, meanwhile make sure they can be conglutinated firmly. |

|

|

3.FineTrimmingunit,there are two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel to ensure both sides of the edge smooth and even. |

|

|

|

4.Scraping unit for a perfect finishing of the applied edge. Buffing unit is equipped with cotton polishing wheels to make smooth surface by end-polishing. |

1) No matter container shipping or LCL shipping, the machine will be packaged with standard plywood case and plastic flim rolling all around the machine for anti-dust.

2) Usually, If have machine in stock, it can deliver 2 days after deposit, if no, can be deliver within 7 days after deposit.