- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Sn42/Bi57/Ag1

-

Shape:

-

Powder

-

Material:

-

Tin Bismuth Silver Alloy, Tin Bismuth Silver alloy

-

Chemical Composition:

-

Sn Bi Ag

-

Product Name:

-

Smt Solder Powder

-

Model:

-

Sn42/Bi57/Ag1

-

Powder Size:

-

T2.5,T3,T4,T5,T6

-

Color:

-

Grey

-

Package:

-

5kg/bag,25kg/barrel

-

Keyword:

-

Solder Powder

-

Melting Point:

-

138-143

-

Certificate:

-

ISO9001,ISO14001,REACH,TSCA,RoHS

Quick Details

-

Application:

-

PCB SMD LED Electronic Assembly, PCB LED SMD Electronic Assembly

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HuaKe

-

Model Number:

-

Sn42/Bi57/Ag1

-

Shape:

-

Powder

-

Material:

-

Tin Bismuth Silver Alloy, Tin Bismuth Silver alloy

-

Chemical Composition:

-

Sn Bi Ag

-

Product Name:

-

Smt Solder Powder

-

Model:

-

Sn42/Bi57/Ag1

-

Powder Size:

-

T2.5,T3,T4,T5,T6

-

Color:

-

Grey

-

Package:

-

5kg/bag,25kg/barrel

-

Keyword:

-

Solder Powder

-

Melting Point:

-

138-143

-

Certificate:

-

ISO9001,ISO14001,REACH,TSCA,RoHS

Product Description

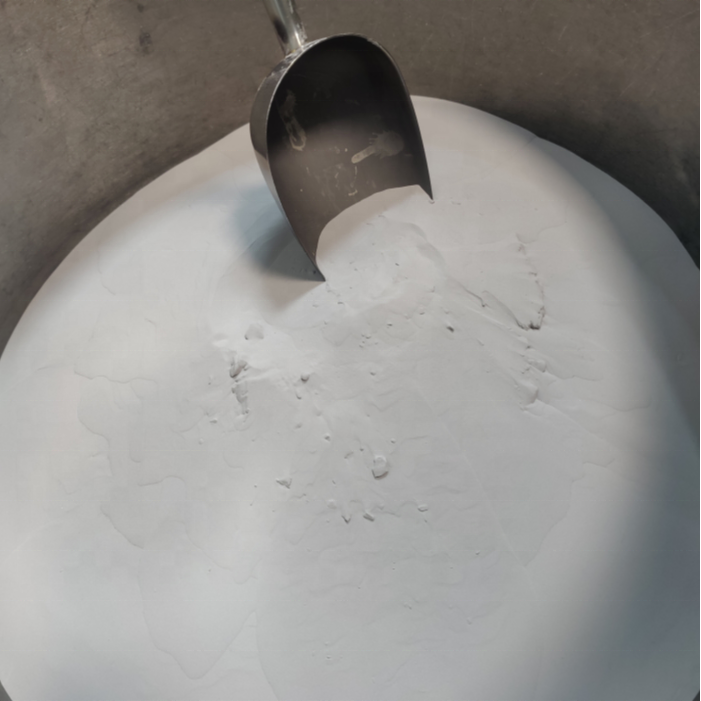

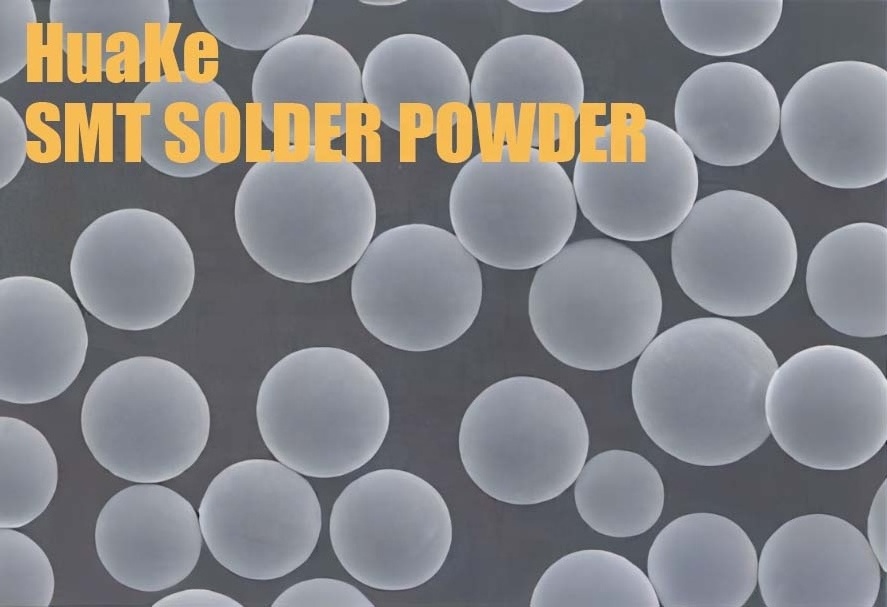

Type of Alloy Powder

We produce electronic grade, low-oxide, spherical solder powder composed of SnPb, SnPbAg, SnPbBi, SnBi, SnBiAg and SnAgCu Alloy Series in the industry standards.

|

Product Name

|

SMT Solder Powder

|

|

Model

|

Sn42/Bi57/Ag1

|

|

Material

|

Sn Bi Ag Alloys

|

|

Powder Size

|

T2.5,T3,T4,T5,T6

|

|

Melting Point

|

138-143℃

|

|

Function

|

Mainly used in the manufacture of solder paste, carbon products, friction materials, oil bearing and powder metallurgy structural materials.

|

|

Standards

|

IEC,IPC and other international standards

|

|

Production Capacity

|

Monthly 200-250 tons

|

|

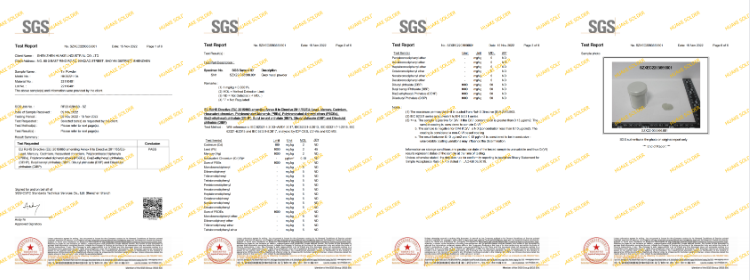

Certificates

|

ISO9001,ISO14001,REACH,TSCA,RoHS,SGS

|

|

Package

|

5kg/bag,25kg/bucket

|

-

Product Features:

1,Solder powder has smooth surface and good printing performance.

2,The oxygen content is precisely controlled to ensure the viscosity stability of the solder paste.

3,The proportion of trueball is high, the particle size distribution is concentrated, and the proportion of powder outside the particle size range is low.

4,The alloy composition is accurate, pure raw material ingredients, and the impurity content is extremely low.

Where to Use:

These solders are primarily used in the electronics industry for manufacturing sensitive components using surface mount technology (SMT).

Classification:by size type

The table below shows the classification type of solder powder compared with the mesh size and particle size.

The most common solder powder sizes for SMT are type 3 (T3), type 4 (T4), and type 5 (T5). The lower the number, the larger the particle size within the solder powder.

|

Type designation[IPC]

|

Mesh size in lines per inch

|

Particle sizes

(in μm)

|

Oxygen content

(ppm)

|

Gullwing Lead Pitch

(mm)(in)

|

Square/Circle Aperture

(mm)(in)

|

Dispense Dot Diam

(mm)(in)

|

|

T2

|

-200/+325

|

45-75

|

<80

|

0.65/0.025

|

0.65/0.025

|

0.80/0.030

|

|

T3

|

-325/+500

|

25-45

|

<90

|

0.50/0.020

|

0.50/0.020

|

0.50/0.020

|

|

T4

|

-400/+635

|

20-38

|

<120

|

0.30/0.012

|

0.30/0.012

|

0.30/0.012

|

|

T5

|

-500/+635

|

15-25

|

<150

|

0.20/0.008

|

0.15/0.006

|

0.25/0.010

|

|

T6

|

-635

|

5-15

|

<200

|

0.10/0.004

|

0.05/0.002

|

0.10/0.004

|

Packing and Delivery:

Company Introduction

Shenzhen Huake Industrial Co., Ltd. was founded in 2002. It is a leading enterprise with complete tin industry chain in China and a large-scale specialized comprehensive enterprise integrating research and development, production, sales and service of electronic welding materials and electronic new materials.

In the development process, Huake Industry insists on the principle of market demand-oriented, customer-centered, reputation-based, and quality-to-life,setting up a complete R&D team and a modern management system,committed the pursuit of perfect quality,constantly accelerating the research and development of

products, constantly satisfying customers and exceeding the needs of customers, and striving to become a leader in the field of electronic soldering materials.

Huake Industry's products are widely used in PCB plating,THT,HASL, SMT,etc.,enjoying a good reputation in related fields, with a number of well-known large IT and electronic manufacturing Corporate customers, covering a wide range of electronics, communications, automotive, LED, and electrical appliance manufacturing.

Huake Industry has established branches in Suzhou, Chongqing, Hangzhou, Qingdao, Xiamen and other major cities, forming a huge sales and service network, and is committed to becoming an overall solution provider and one-stop electronic new material service provider for electronic welding materials. We are in line with the team spirit of "honesty, truth-seeking, efficiency and innovation", the corporate culture concept of benevolence and harmony, first-class product quality and service, and win the support and trust of customers. We are willing to work together with friends from all over the world and colleagues from all walks of life to seek common development.

Hot Searches