- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hengtailong

-

Voltage:

-

220/380/440/460v / Customization

-

Dimension(L*W*H):

-

3200*920*2100mm / Customization, Refer to the model, 3200*920*2100mm(Dimension can be custom

-

Weight:

-

2000 KG

-

Features:

-

Energy-saving

-

Spare parts:

-

Screw propeller,heating ring

-

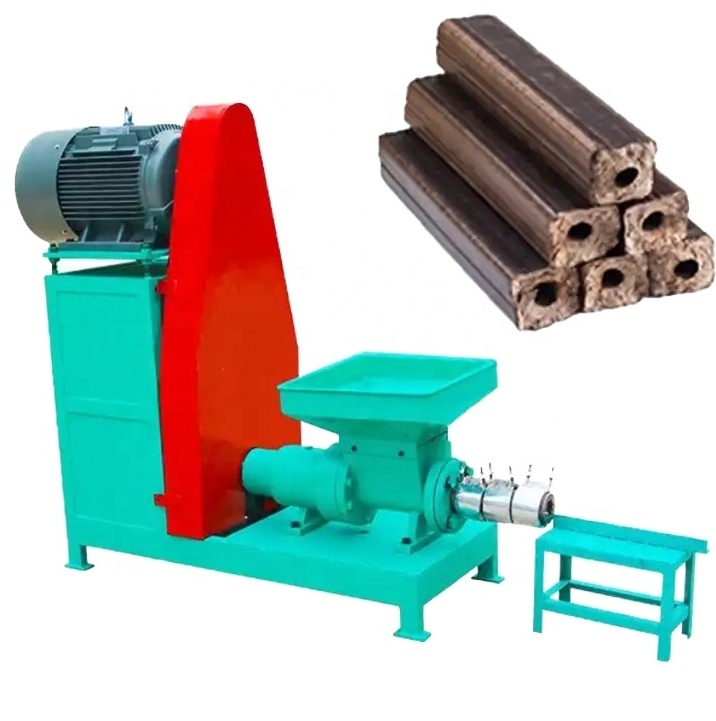

Briquette shape:

-

Square, cube,hexagonal,cylinder

-

Final shapes:

-

Round, rectangular, hexagonal stick shape and others

-

Raw material:

-

Sugarcane, firewood, sawdust, rice husk

-

Function:

-

Make Stick Shape Briquette

-

Mositure content:

-

8%-12%

-

Usage:

-

Biomass briquettes

-

Product name:

-

Sale Wood Biomass Waste Sawdust Briquette Charcoal Making Machine

Quick Details

-

Application:

-

Manufacturing Plant

-

Production Capacity:

-

High, 1-50tph, 300kg-5000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengtailong

-

Voltage:

-

220/380/440/460v / Customization

-

Dimension(L*W*H):

-

3200*920*2100mm / Customization, Refer to the model, 3200*920*2100mm(Dimension can be custom

-

Weight:

-

2000 KG

-

Features:

-

Energy-saving

-

Spare parts:

-

Screw propeller,heating ring

-

Briquette shape:

-

Square, cube,hexagonal,cylinder

-

Final shapes:

-

Round, rectangular, hexagonal stick shape and others

-

Raw material:

-

Sugarcane, firewood, sawdust, rice husk

-

Function:

-

Make Stick Shape Briquette

-

Mositure content:

-

8%-12%

-

Usage:

-

Biomass briquettes

-

Product name:

-

Sale Wood Biomass Waste Sawdust Briquette Charcoal Making Machine

factory price wood chips bamboo coconut shell charcoal briquette making machine

I. Introduction of

wood chips bamboo coconut shell charcoal briquette making machine

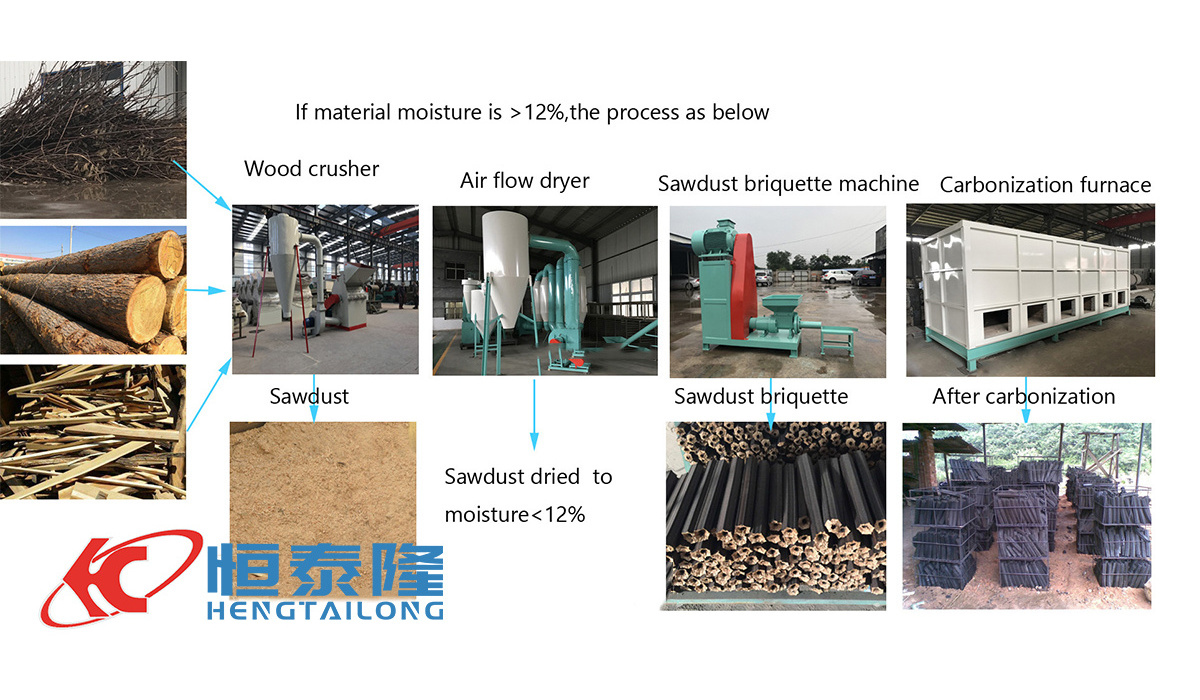

Raw material:

Biomass wastes, such as sawdust,rice husks,coffee husks,rice straw, wheat straw,etc.

Material required: Moisture 5%-12%,size3-5mmIf moisture>12% may need dryer,We have air flow dryer and drum dryer.

If material size >5mm will need hammer mill or wood crusher.

Biomass wastes, such as sawdust,rice husks,coffee husks,rice straw, wheat straw,etc.

Material required: Moisture 5%-12%,size3-5mmIf moisture>12% may need dryer,We have air flow dryer and drum dryer.

If material size >5mm will need hammer mill or wood crusher.

When begin to work,the heating circle heat the machine,then wood briqutte machine can press sawdust without any binder, sawdust pressed by high temperature and high pressure , then the screw press sawust forward,extrusion into a rod-shaped solid rod with center hole.

II.Working Principle of

wood chips bamboo coconut shell charcoal briquette making machine

The use of the inherent characteristics of wood raw materials, the pressure of the screw through the high temperature softening of the biomass material, at high temperature and pressure, the wood raw materials in the lignin cellulose fiber combination to form a semi-finished products with a central hole.

|

Model NO.

|

BY-50

|

BY-50

|

BY-80

|

|

Productivity Kg/h

|

200-250

|

250-300

|

300-400

|

|

Motor power KW

|

18.5 kw

|

40hp

|

18.5kw—22kw

|

|

Weight kg

|

520 kg

|

550kg

|

800 kg

|

|

Out size mm

|

1800*600*1600

|

1800*700*1600mm

|

1800*700*1600

|

|

Moisture

|

5%-10%

|

5%-10%

|

5%-10%

|

III.Main Features of

wood chips bamboo coconut shell charcoal briquette making machine

1.High efficiency:20 seconds 60cm briquette,250-300kg/h.

2.Screw propeller adopts precision casting, special wear-resisting material life for more than ten times higher than that of traditional thrusters. Forming sleeve adopts special formula alloy precision casting, life can be up to 3 month; This cutting-edge technology not only makes the cost is greatly reduced, but also saves manpower.

2.Screw propeller adopts precision casting, special wear-resisting material life for more than ten times higher than that of traditional thrusters. Forming sleeve adopts special formula alloy precision casting, life can be up to 3 month; This cutting-edge technology not only makes the cost is greatly reduced, but also saves manpower.

OUR WORKSHOP

We are a real manufacturer, not a trading company. We have the best after-sales service. The complete set of markene production is produced by ourselves, without the need to buy different machine connection product lines from different manufacturers.

Packing Details &Delivery Time

Packaging Details:

Standard export packing, Spare parts in wooden case, big machines loaded in container,large machines use nude packing, cover with plastic cloth. We export through QingdaoPort, also can be nominated by customer. We have superior cargo agent to arrange thesea shipment for each client, competitive price, secure transportation.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 10 to 20 working days.

Hot Searches