- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kexin

-

Voltage:

-

380V/50HZ/220V50Hz/ 110V50Hz

-

Weight:

-

320 KG

-

Gas output:

-

30m3/h

-

Gasification efficiency:

-

>72%

-

Material feeding consumption:

-

15Kg/H

-

Power supply:

-

380V 50Hz

-

Certificate:

-

CE

-

Types of raw materials:

-

Various agricultural wastes, biomass, waste cartons, etc.

-

Generator type:

-

Gas (syngas) generator set

-

Gasifier type:

-

Downdraft fluidized bed type gasifier

-

Patented product:

-

YES

Quick Details

-

Warranty:

-

1 Year

-

Core Components:

-

Pyrolysis device

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Kexin

-

Voltage:

-

380V/50HZ/220V50Hz/ 110V50Hz

-

Weight:

-

320 KG

-

Gas output:

-

30m3/h

-

Gasification efficiency:

-

>72%

-

Material feeding consumption:

-

15Kg/H

-

Power supply:

-

380V 50Hz

-

Certificate:

-

CE

-

Types of raw materials:

-

Various agricultural wastes, biomass, waste cartons, etc.

-

Generator type:

-

Gas (syngas) generator set

-

Gasifier type:

-

Downdraft fluidized bed type gasifier

-

Patented product:

-

YES

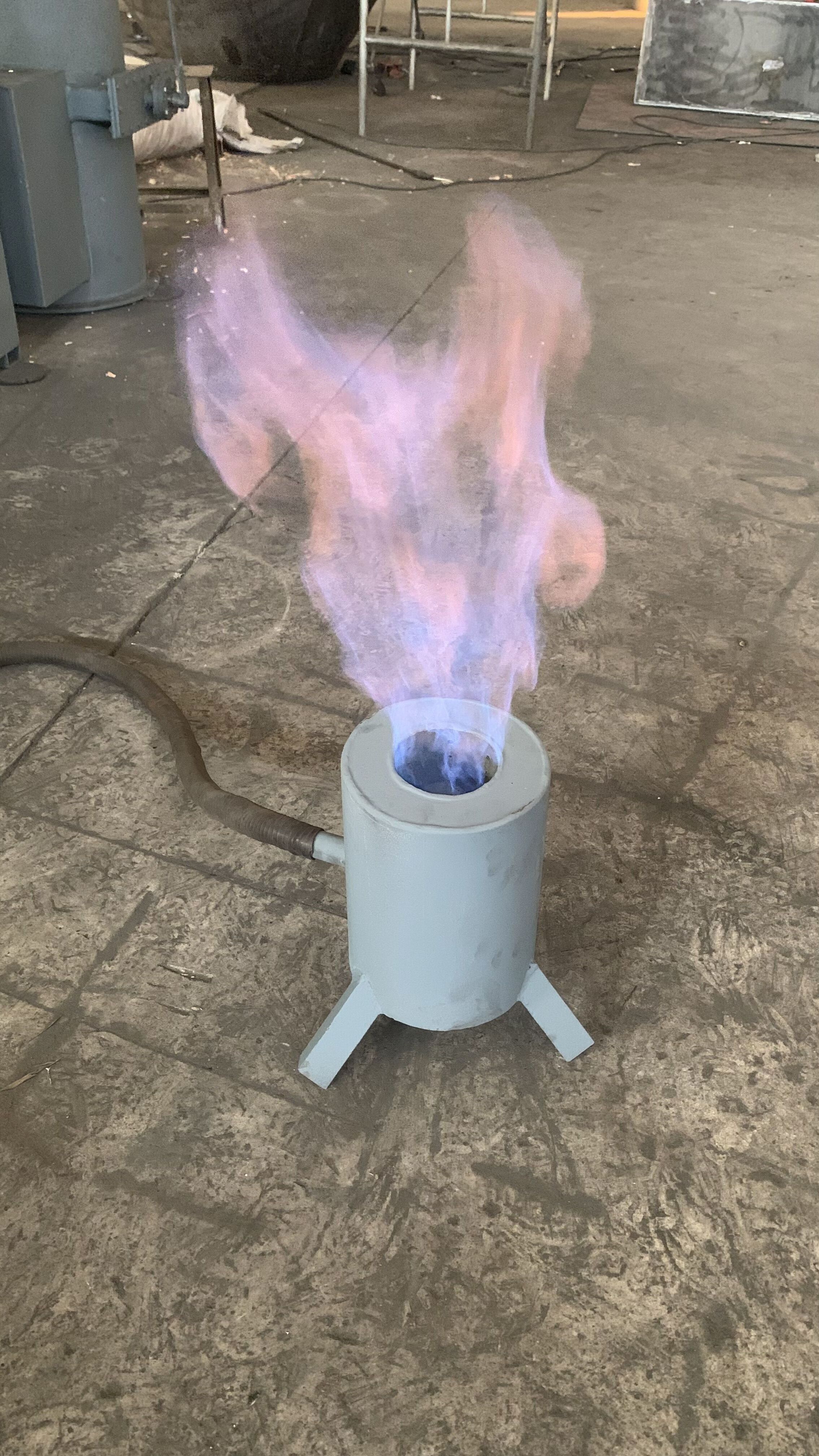

Equipment display

Sale Small Biomass Gasifier For Family Use

Equipment introduction

|

|

1. Gas output: 10m3/h

2. Gas caloric value: 1000-1200Kcal/m3 3. Gasification efficiency :>72% 4. Power supply: 220V50Hz 5. Material Feeding consumption: 5KG/H 6. Certificate: CE 7. Raw material requirements: length size < 30mm,moisture content < 20% |

|

JXQ-10A (Simple type) Specifications:

|

1. Gas output: 10m3/h

2. Gas caloric value: 1000-1200Kcal/m3 3. Gasification efficiency :>72% 4. Power supply: 220V50Hz 5. Material Feeding consumption: 5KG/H 6. Certificate: CE 7. Raw material requirements: length size < 30mm,moisture content < 20% |

|

JXQ-30A (Simple type) Specifications: |

1. Gas output: 30m3/h

2. Gas caloric value: 1000-1200Kcal/m3 3. Gasification efficiency :>72% 4. Power supply: 220V50Hz 5. Material Feeding consumption: 15-18KG/H 6. Certificate: CE 7. Raw material requirements: length size < 30mm,moisture content < 20%. |

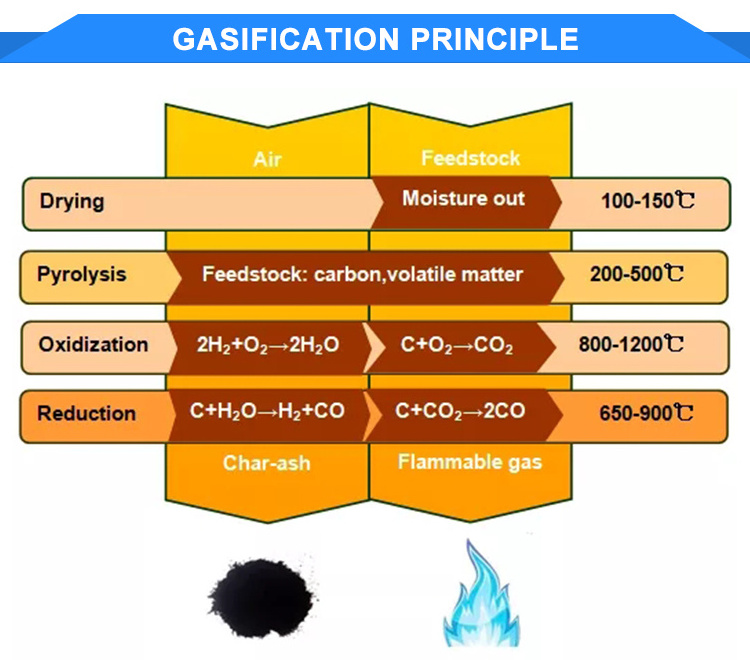

Gasification principle

Biomass raw materials enter into the reactor of gasifier, which is heated and dried. Then, with the increase of temperature, the volatile matter is separated out and pyrolyzed (cracked) at high temperature. The pyrolysis gas and biomass react with the air supplied in the oxidation zone to produce CO2 and steam. The heat generated by combustion is used to maintain the endothermic reaction of drying, pyrolysis and lower reduction zone. The gas generated after combustion will go down through the reduction zone and react with the high temperature carbon layer (C+ CO2 = 2CO, C + HO2 = H2 + CO) to generate biomass syngas containing Co, H2, CH4, CMHN and other components, which is led out from the lower part and sent out for use after the tar and other impurities are removed by the purification system. The ash is discharged from the lower part of the gasifier.

Types of raw materials

The gasification power generation system is suitable for various biomass structures such

as peanut hull, rice hull, corn cob, cotton straw, corn straw, wood chips, branches, trees, chicken manure, pig manure, cow

manure, organic municipal waste, industrial organic waste, such as plastic, rubber, cloth, paper hull, etc*

(the total content of plastic and rubber is less than 30%).

The requirements of biomass gasifier for raw materials are as follows:

1) Size requirements of raw materials: biomass raw materials with bulk or granular shape less than 30 mm.

2) Water content of raw materials: less than 20%.

as peanut hull, rice hull, corn cob, cotton straw, corn straw, wood chips, branches, trees, chicken manure, pig manure, cow

manure, organic municipal waste, industrial organic waste, such as plastic, rubber, cloth, paper hull, etc*

(the total content of plastic and rubber is less than 30%).

The requirements of biomass gasifier for raw materials are as follows:

1) Size requirements of raw materials: biomass raw materials with bulk or granular shape less than 30 mm.

2) Water content of raw materials: less than 20%.

Project presentation

Our customers

Equipment delivery

Ordering process

Company profile

Qingdao Kexin New Energy Technology Co., Ltd., founded in 1998 (Pingdu Tianwei environmental protection gas equipment plant), is located at No. 71, Hong Kong Road, Pingdu City, Qingdao city. It is a high-tech biomass syngas power generation equipment and its supporting products, which integrates equipment research and development, production and manufacturing, sales, operation and export trade.

Since its establishment for 20 years, adhering to the business philosophy of "integrity", "innovation", "professionalism" and "pragmatism", the company has devoted itself to the development and research and development of biomass energy. Aiming at the new functions and characteristics of new energy materials biomass materials, we have successfully developed kx series biomass gasification equipment and syngas power generation series products: JXQ series Series (simple type), KX series (downdraft fluidized bed type) biomass gasification equipment, KX series biomass syngas power generation system, biomass syngas special hot blast stove, biomass raw material drum dryer, biomass shredder, drum drying equipment, dust collector and other products. The whole set of biomass gasification power generation equipment has obtained a number of national invention patents and utility model patents.

KX series fluidized bed biomass gasification equipment has passed the EU CE certification, and has been exported to many countries with high requirements on equipment quality and environmental protection quality, such as the United States, Italy, Japan, South Korea, Switzerland, Russia, Singapore and so on.

Our company is committed to meet the needs of customers from all over the world and provide customers with higher quality after-sales service. With the basic principles of "reasonable price", "high-quality products", "punctual delivery time" and "good after-sales service", we sincerely look forward to cooperating with friends at home and abroad, developing together, making progress together and creating a mutually beneficial and win-win future.

Why Choose Us

Hot Searches