- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sinrad

-

Model Number:

-

SR-S200

-

Name:

-

Cross-section Analyzer

-

Frequency:

-

50HZ

-

Voltage:

-

220V

-

Cutting range diameter:

-

0.10mm -20.00mm

-

Camera:

-

3 million pixels

-

Analysis:

-

Compression ratio, porosity, pressure size, etc

-

Net weight:

-

35KG

-

Dimensions:

-

500x350x350mm

-

Optical lens:

-

0.7~4.5X Pumisco End stop

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic, 600W

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sinrad

-

Model Number:

-

SR-S200

-

Name:

-

Cross-section Analyzer

-

Frequency:

-

50HZ

-

Voltage:

-

220V

-

Cutting range diameter:

-

0.10mm -20.00mm

-

Camera:

-

3 million pixels

-

Analysis:

-

Compression ratio, porosity, pressure size, etc

-

Net weight:

-

35KG

-

Dimensions:

-

500x350x350mm

-

Optical lens:

-

0.7~4.5X Pumisco End stop

Product Description

Product Description

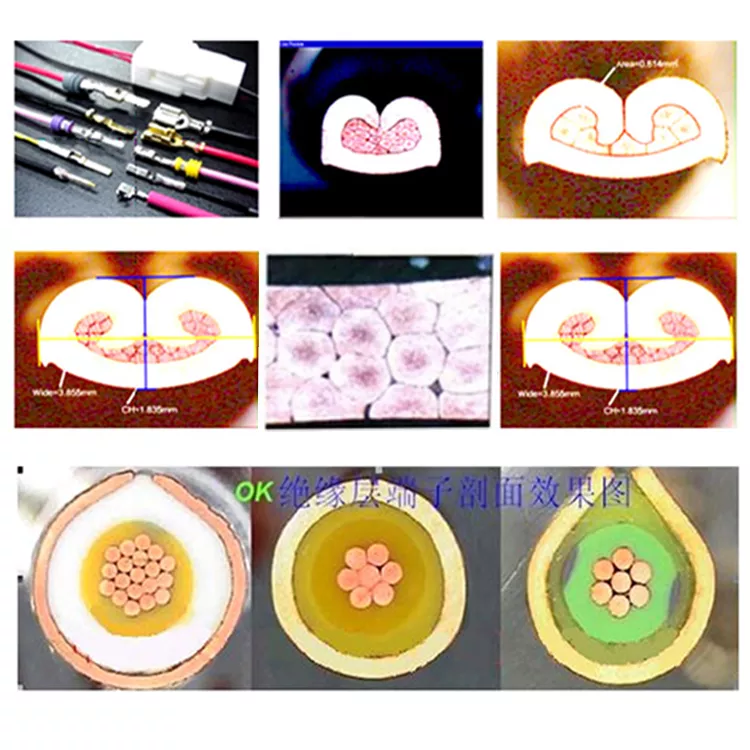

Terminal section analyzer

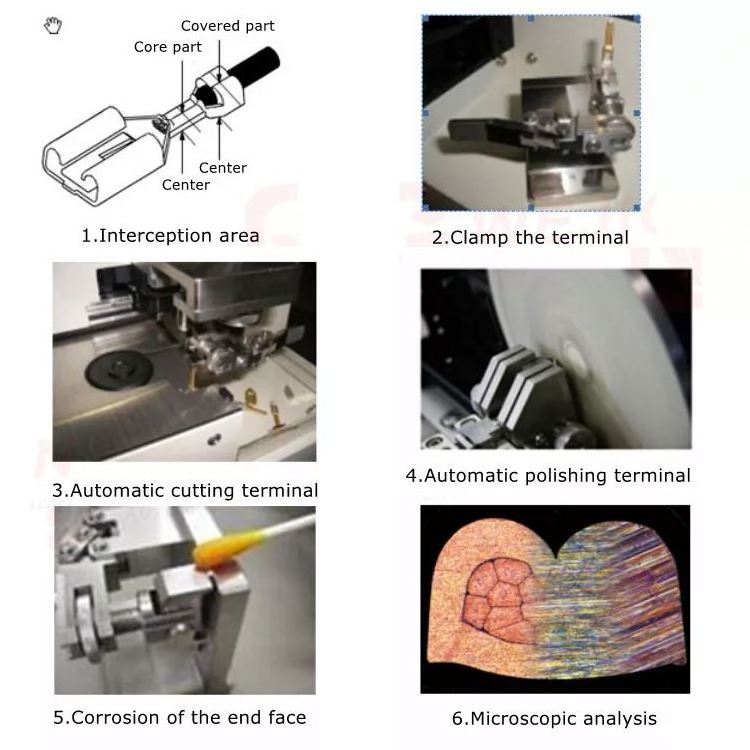

Application:

Cut product terminal cross section, calculate its physical parameters, confirm whether meet the product application requirements.

Main analysis parameters:

Compression ratio, number of wire harness, crimping height, crimping width, sectional area, support height, support Angle, burr width, burr height, etc.

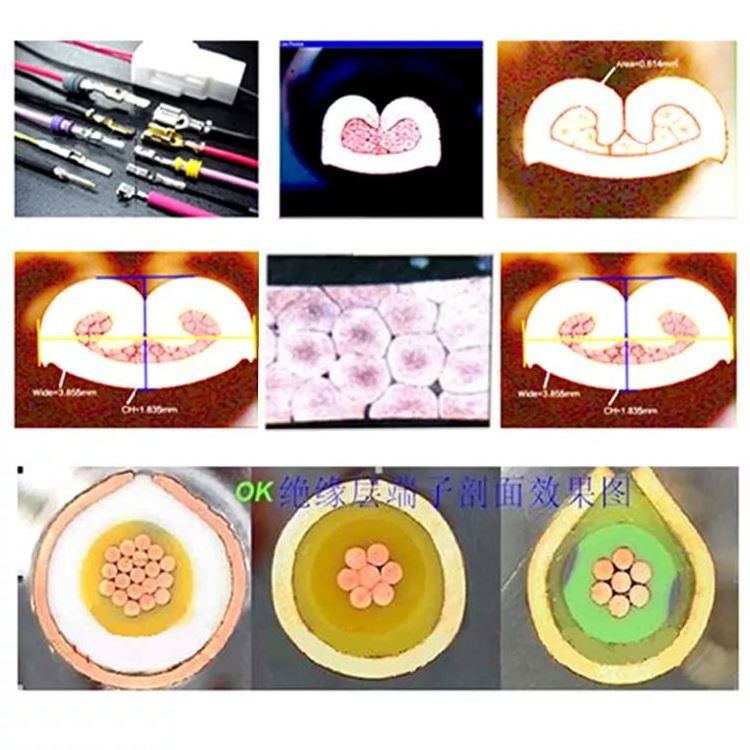

Part show for reference

Section analysis report

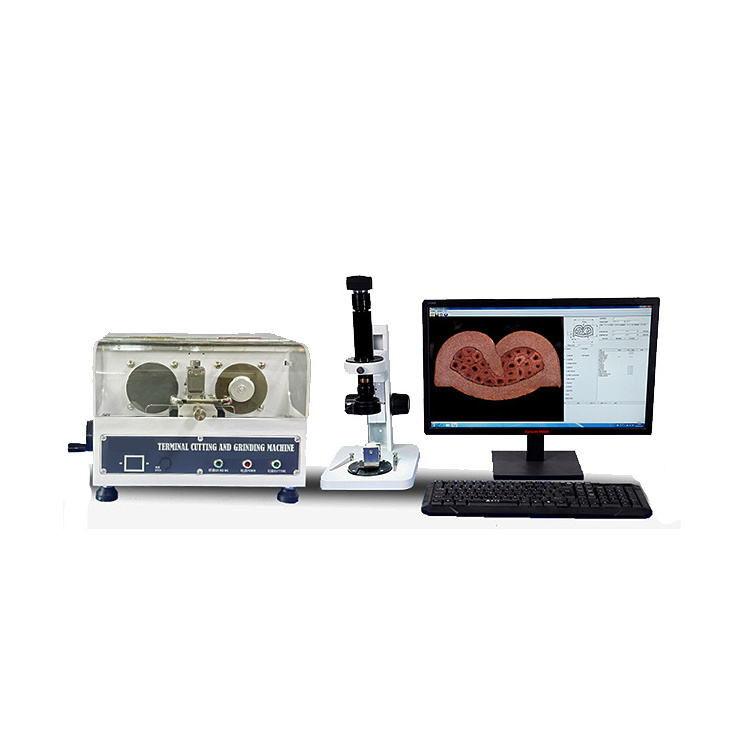

Specification

Specification

|

item

|

value

|

|

Motor speed (cut/grind)

|

2800RPM/1400 RPM

|

|

Cutting range diameter

|

Ø 0.10mm - Ø 24.00mm

|

|

Cutting wheel diameter

|

φ110 x 0.5 xφ20mm

|

|

Etched part

|

Professional Terminal Section Cleaning Fluid

|

|

Corrosion Time

|

5~30 s

|

|

Grinding disc diameter

|

100mm 1000# 2000# 3000# can select

|

|

Corrosion part Corrosion time

|

5-30sec

|

|

Power switch

|

220V/50HZ

|

|

Imaging system

|

1/3″ professional CCD high-definition imaging system(3 million pixels (CCD gigabit network,The card access screen is clear and transmission speed Fast and stable))

|

|

Terminal dedicated analysis measurement Software

|

1PCS

|

|

Magnification

|

36X~230X continuous zoom (support digital to 500X)

|

|

Measurement accuracy

|

0.01-50sqmm

|

|

Optical lens

|

0.7~4.5X (Hong Kong joint venture) Pumisco End stop

|

|

Software version

|

version V3.2, enhanced measurement tools including compression ratio, etc.

|

|

Lighting source

|

All white adjustable LED lighting device (cold light)

|

|

weight

|

35KG

|

|

Warranty period

|

1 year

|

After the terminals are clamped by a dedicated harness clamp, the cutting disc and the grinding disc are independently controlled, and the speed can be easily controlled. when grinding and polishing the terminal section, it is necessary to control the speed according to the material and size of the terminal.During grinding and polishing, a rail structure with scales is designed that can be fine-tuned up and down, which can accurately control the height of the terminals for customers. The time required for terminal cutting, grinding and polishing is 2 to 3 minutes. Very fine lines exceeding AWG38 can be displayed clearly. Use newly developed cross-section assessment.It can measure CH and CW and calculate the cross-sectional area instantly.

The measurement accuracy at the maximum magnification is 1µm.

It only takes 2 minutes to complete the sample making process for wire harness terminal inspection!!

Software funtion:

Compression ratio, number of harnesses, crimp height, crimp width, cross-sectional area, support height, support angle, burr width, burr height, etc.

Features

Features

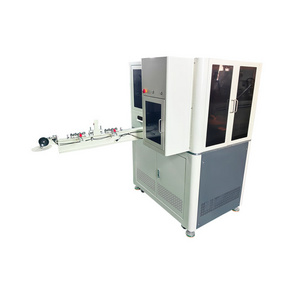

1. Use linear guide rails to ensure installation accuracy. 2. The motor is installed horizontally to ensure that the rotation deflection is small. 3. Laser infrared alignment ensures fast alignment of the cutting position. 4. Optional movable XY working platform with 360-degree rotating table, convenient for terminal cross-section sampling. 5. Increase the drainage system to facilitate cleaning of the machine. 6. The fixture is in front for easy installation and adjustment. 7. Trigger switch to ensure personnel safety. 8. Velcro sandpaper, quick replacement. 9. Using a 5-megapixel industrial camera, it can capture high-definition pictures dynamically. 10. Built-in analysis software for measurement standards, export reports quickly and quickly. 11. Using seven-inch touch system, intelligent cutting program 12. Up to 30 groups of programs can be saved 13. Increase key operation, prolong service life.

Software function:

Compression ratio, number of wire harness, crimping height, crimping width, sectional area, support height, support Angle, burr width, burr height, etc.

other ultrasonic welding machine

other ultrasonic welding machine

Packing & Delivery

Packing & Delivery

|

Size

|

36*34*76CM

|

|

Weight

|

55kgs

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is

too tigher,we will use pe film for packing or pack it according to customers special request. |

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches