- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Aolong

-

Model Number:

-

aolong

-

Tube voltage:

-

Max.90kv~160kv

-

Tube current:

-

178~1000μA

-

Focus size:

-

1~5μm

-

Geometric magnification:

-

10~10000+

-

Flat panel detector:

-

18*15mm

-

Table Stroke(X axis):

-

300mm

-

Table Stroke(Y axis):

-

350mm

-

Moving speed:

-

0.1~0.5m/min continuously variable

-

Max.load capacity:

-

2kg

-

Certification:

-

CE,ISO9001,ISO14001

Quick Details

-

Warranty:

-

1 year

-

Power:

-

Electronic

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Aolong

-

Model Number:

-

aolong

-

Tube voltage:

-

Max.90kv~160kv

-

Tube current:

-

178~1000μA

-

Focus size:

-

1~5μm

-

Geometric magnification:

-

10~10000+

-

Flat panel detector:

-

18*15mm

-

Table Stroke(X axis):

-

300mm

-

Table Stroke(Y axis):

-

350mm

-

Moving speed:

-

0.1~0.5m/min continuously variable

-

Max.load capacity:

-

2kg

-

Certification:

-

CE,ISO9001,ISO14001

◆ Contact Us for Detailed Information ◆

Description

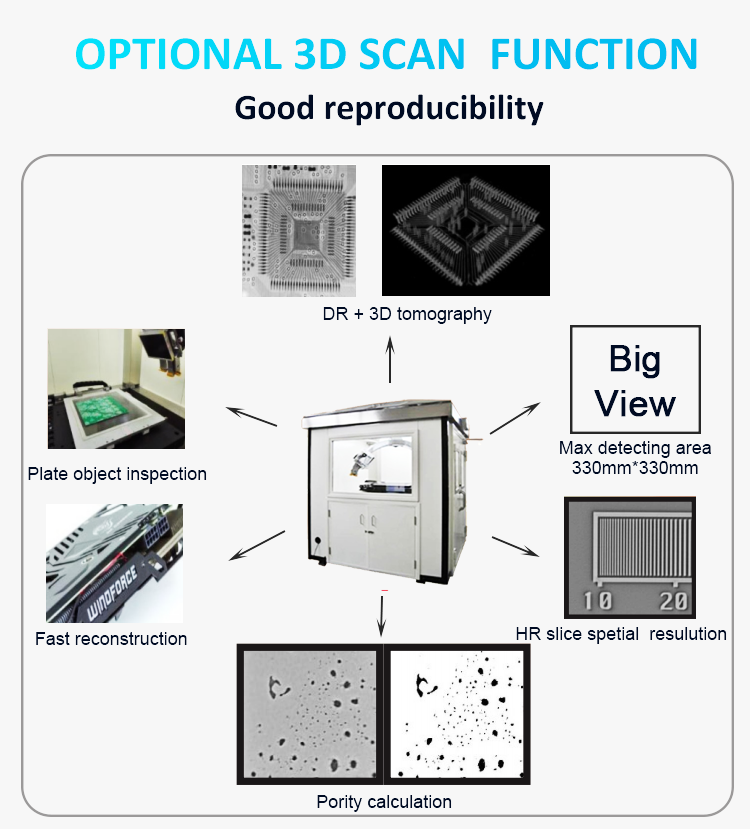

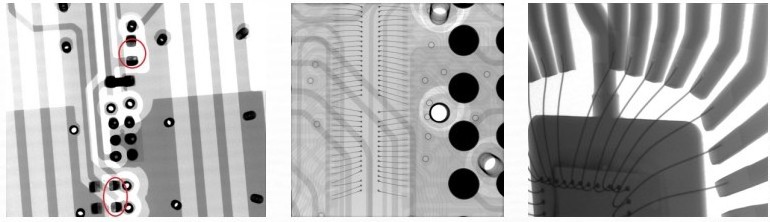

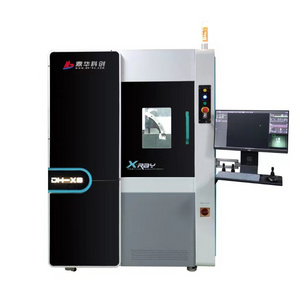

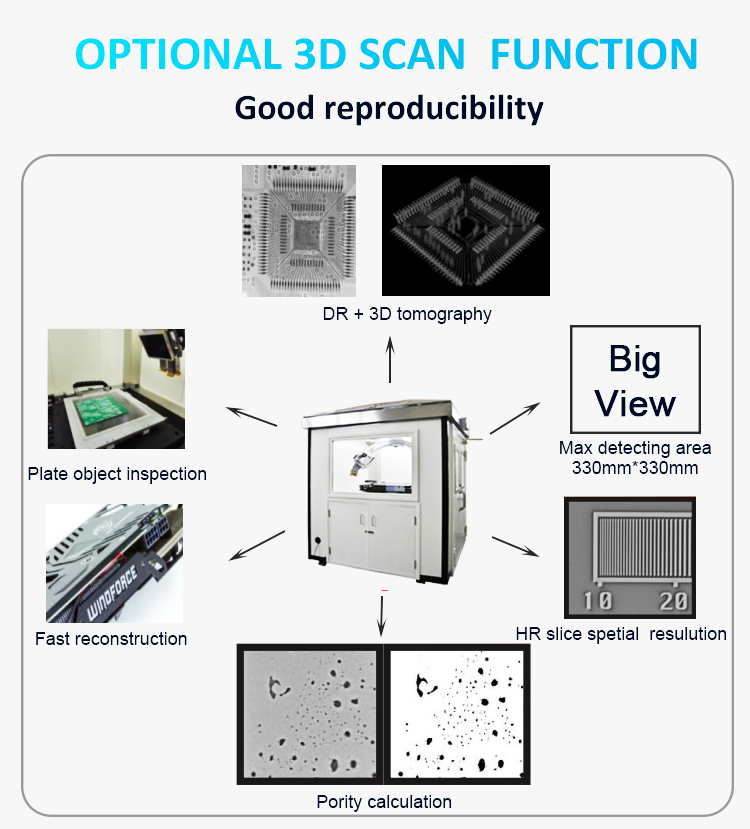

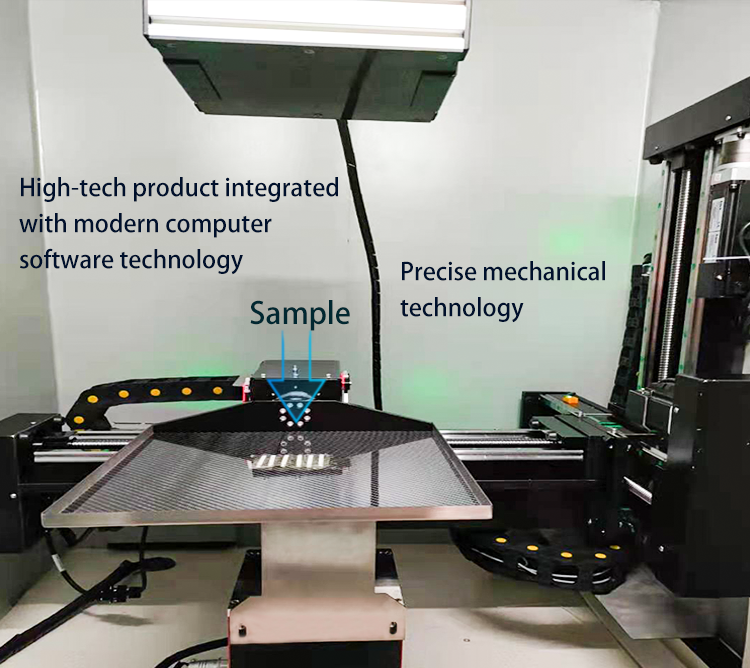

X-ray Microfocus Inspection System

This system is a high-tech product integrated with modern computer software technology, precise mechanical technology,optical technology, electronic technology, sensor technology, NDT technology and image processing technology. lt is an efficient method for product research, invalidation analysis, high reliable fitering, quality evaluation and artifact improvement.The technology of this product obtained the national patent.

Main Performance and Specifications

|

|

Model

|

XJD-90

|

XJD-130

|

XJD-160

|

||

|

X-ray unit

|

Tube voltage

|

Max.90kv

|

Max.130kv

|

Max.160kv

|

||

|

|

Tube current

|

178μA

|

320μA

|

1000μA

|

||

|

|

Focus size

|

5μm

|

7μm

|

1μm

|

||

|

|

Geometric magnification

|

10-64

|

10-58

|

10-2000

|

||

|

|

Total magnification

|

700

|

640

|

10000+

|

||

|

Detector

|

Flat panel detector

|

18*15cm

|

18*15cm

|

18*15cm

|

||

|

X/Y table

|

Size

|

300(X)*350(Y)mm

|

|

|

||

|

|

Stroke(X axis)

|

300mm

|

|

|

||

|

|

Stroke(Y axis)

|

350mm

|

|

|

||

|

|

Moving speed

|

0.1-0.5m/min continuously variable

|

|

|

||

|

|

Max.load capacity

|

2kg

|

|

|

||

|

|

Operation

|

Positioning by using the mouse(with/without joystick on the control board)

|

|

|

||

|

|

Positioning control

|

NC control using teaching data

|

|

|

||

|

|

Sample rotation&tilting

|

Rotation:360° Tilting:±30°

|

|

|

||

|

Vertical movement of x-ray detector

|

Detector up/down

|

Stroke 600mm Positioning by using mouse or switches on the control board

|

|

|

||

|

Optional functions and accessories

|

|

The asterisked(*)parts are optional

|

|

|

||

Image Processing Software

|

Item

|

Specifications

|

|

|

|

|||

|

Image processing

|

●Powerful software for image improvement function including integration brightness,contrast,gamma correction, and shadingcorrection.

●Various image processing function including spatial filter(for edge detection and image enhancement),logical and arithmetic operations, and FFT (Fast Fourier Transform). |

|

|

|

|||

|

Brightness and Density measurement

|

●Measurement of brightness and density

●Measurement tool of histogram of brightness in an arbitrary area

●Measurement tool of area ratio for either brightness ordensity

|

|

|

|

|||

|

Measurement of forms and conditions

|

●Function for spatial/intensity calibration,for dimensional measurement, and for manual counting tools

●Particle analysis tools(discrimination of targetsubstances through the difference in brightness)

●Approximately 30 kinds of measurement items including number of pieces, and diameter

●Separation of coagulated particles, merging,classification, and particle density

measurement |

|

|

|

|||

|

Display and Output

|

●Histogram

●Pseudo color display Report generator function convenient for the preparation of reports

●Output of graphs, measurement data, or image to Excel

|

|

|

|

|||

|

Storage and Transmission

|

●Image database function

●Image transmission and reception, and E-mail transmission via Internet

|

|

|

|

|||

|

Customization

|

●Powerful macro function (using a language in according with Visual Basic) ●Automatic macro recording of manual operation

●Execution of macro through Visual Basic/C++

|

|

|

|

|||

Applications

●To inspect BGA,CSP and flip chip

●To inspect the welding of PCB

●To inspect all the kinds of battery

●To inspect lC encapsulation

●To inspect capacitance and resistance

●To inspect the flaw of the metal material and dielectric material

●To inspect the inner structure and groupware of the light material

●To inspect galvanothermy tube, pearl and precision apparatus

Other on-line inspection system

Company

Convincing Inspection Solution Supplier

Over 50 years, Aolong Group focuses on the Non-destructive Testing technologies and gives our customers the best inspection solutions with the high quality radiographic equipment with simple operation and complete functions.

China Radiographic equipment R&D Center

Aolong Group contributed to performing NDT for Chinese lanched “Shenzhou spaceship” system, and built the Academician experts workstation in the factory, which made us being awarded as the Chinese radiographic equipment R&D center.

Global Non-destructive testing service pioneer

Our industrial X-ray equipment have been sold to over 60 countries and built our agents and after sale service centers in Europe, U.S, Africa, and Asia. We can supply both high quality products and good after sale service.

Over 50 years, Aolong Group focuses on the Non-destructive Testing technologies and gives our customers the best inspection solutions with the high quality radiographic equipment with simple operation and complete functions.

China Radiographic equipment R&D Center

Aolong Group contributed to performing NDT for Chinese lanched “Shenzhou spaceship” system, and built the Academician experts workstation in the factory, which made us being awarded as the Chinese radiographic equipment R&D center.

Global Non-destructive testing service pioneer

Our industrial X-ray equipment have been sold to over 60 countries and built our agents and after sale service centers in Europe, U.S, Africa, and Asia. We can supply both high quality products and good after sale service.

Packing & Delivery

Contact Me

Contact: Jane Cel/wechat/whatsapp: +86 13898510966

Office Tel: +86 3458129

Email: zyhjane@hotmail.com

Office Tel: +86 3458129

Email: zyhjane@hotmail.com

Hot Searches