- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HG

-

Voltage:

-

220V/110V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Video Technical Support

Product Description

Product Features

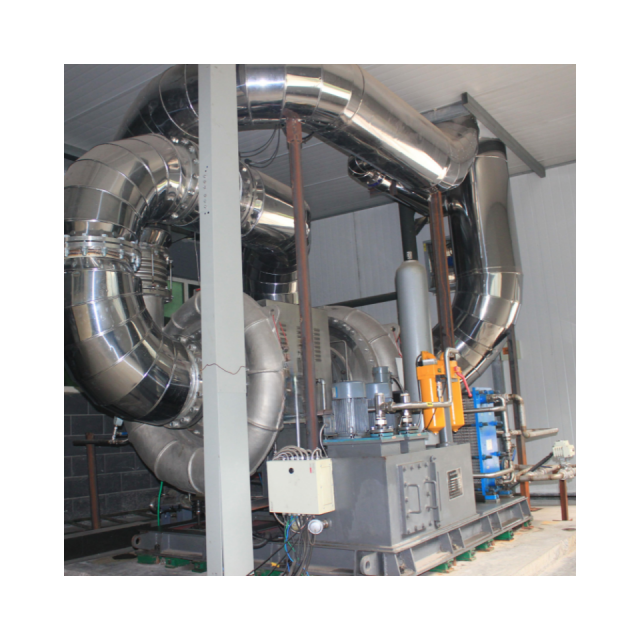

Introducing our professional-grade Sugar Evaporator, designed to meet the diverse needs of the sugar production industry. With a wide range of features and capabilities, this versatile equipment is perfect for sugar cane, beet, and sorghum processing, as well as starch and fruit syrup evaporation.

Our Sugar Evaporator is built to cater to various production lines, including cane sugar, white sugar, sorghum sugar, and sugar production from sugar cane, sugar beet, and sorghum. This equipment is also suitable for the production of brown sugar and the evaporation and crystallization of liquid sugars, such as fruit glucose syrup.

With its advanced technology and robust construction, our Sugar Evaporator ensures efficient and precise evaporation and concentration of starch sugars, cane sugars, low-polymer xylose, and erythritol, among others. It guarantees high-quality end products with excellent flavor and texture.

The Sugar Evaporator is equipped with state-of-the-art components and controls, allowing for easy operation and maintenance. Its automated features ensure consistent and reliable performance, minimizing downtime and maximizing productivity. The equipment is also designed with safety in mind, meeting all necessary industry standards.

Investing in our Sugar Evaporator means investing in a reliable and efficient solution for your sugar production needs. With its exceptional performance, versatility, and durability, this equipment is a valuable addition to any sugar processing facility.

Choose our Sugar Evaporator and experience the difference in your sugar production process. Trust in our expertise and commitment to delivering high-quality equipment that meets the demands of the modern sugar industry.

Working Principle

Water vapor is often used as a heating source in industry, and most of the evaporated materials are aqueous solutions. After water is evaporated, it becomes steam. For differentiation, the steam evaporated from the evaporator is generally referred to as secondary steam. The evaporation process completed in an evaporator, where the secondary steam is directly discharged after being recondensed and no longer used, is called single effect evaporation. The evaporator using this single effect evaporation method is called a single effect evaporator.

Working principle: A single effect evaporator is composed of a set of heating chambers and separation chambers. The heating chamber is equivalent to a heat exchange device, and the heating medium is steam, while the separation chamber is equivalent to a gas-liquid separation device. The material liquid enters from the middle of the heating chamber, and during the entire heating chamber process, the material liquid receives heat, vaporizes water, and the concentrated material liquid is discharged from the bottom of the heating chamber. The gas vaporized from the feed liquid is called secondary steam. The secondary steam enters the condenser, and the secondary steam is directly condensed by the cooling water. The cooling water is discharged from the bottom, and non condensable gases such as air are discharged from the top.

Product Application

Single effect falling film evaporator is used for low-temperature evaporation of liquids in industries such as food, chemical. It can continuously feed and discharge materials, with short heating time and low evaporation temperature. The liquid can pass through the equipment once to meet the required concentration requirements. It has little impact on the color, flavor, and nutritional composition of the product, and is particularly suitable for the evaporation of heat sensitive materials such as milk.

Product Specifications

Energy consumption: 1.17T steam/ton of water, 20KW/ton of water

Specification: Single module maximum 5T/D, can be combined with multiple modules 10-200T/D

Material selection options: 316L, 2205/2507, titanium alloy

For more details, please feel free to contact us

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches