The whole construction process is dust free and pollution-free, which is conducive to environmental protection and the health of construction personnel

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

750 KG

-

Power:

-

30KW

-

Dimension(L*W*H):

-

1940*380*1100mm

-

Product name:

-

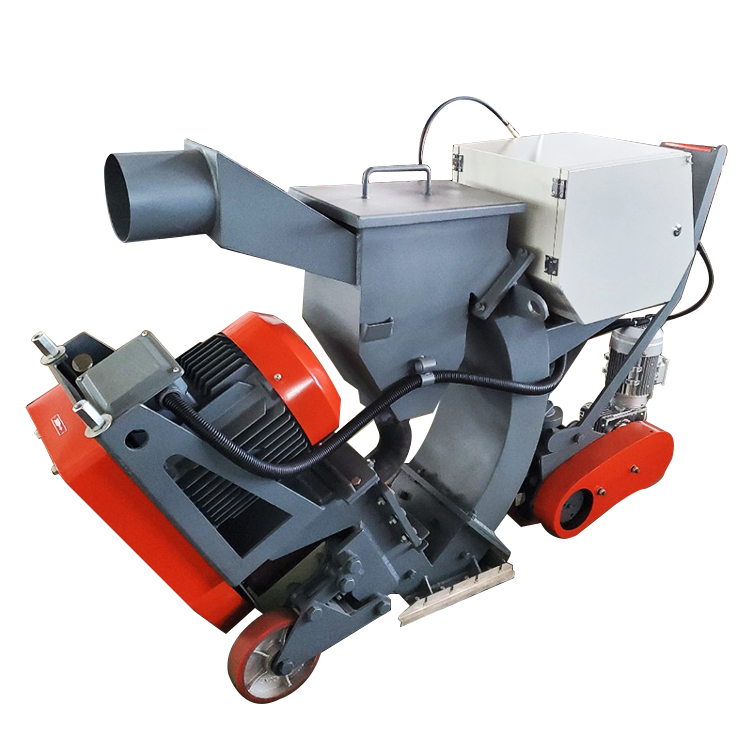

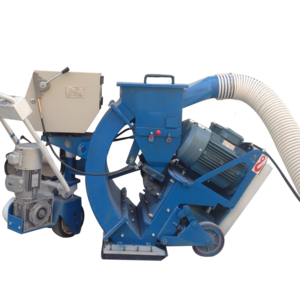

Road Shot Blasting Machine

-

Application:

-

Road Surface Blast Cleaning

-

Function:

-

Beam Shot Blasting Cleaning

-

Blasting media:

-

Steel Sand

-

Dust collector:

-

Remove Dust

-

Operate:

-

Automatic Continuous Blasting Cleaning

-

Feature:

-

Durable

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KimBaiYi

-

Core Components:

-

other

-

Weight (KG):

-

750 KG

-

Power:

-

30KW

-

Dimension(L*W*H):

-

1940*380*1100mm

-

Product name:

-

Road Shot Blasting Machine

-

Application:

-

Road Surface Blast Cleaning

-

Function:

-

Beam Shot Blasting Cleaning

-

Blasting media:

-

Steel Sand

-

Dust collector:

-

Remove Dust

-

Operate:

-

Automatic Continuous Blasting Cleaning

-

Feature:

-

Durable

The shot blasting machine uses the shot blasting wheel to generate centrifugal force and wind force at high speed. Under the centrifugal force, the projectile is thrown into the directional sleeve by the window of the shot parting wheel, and then thrown out through the window of the directional sleeve, and the high-speed rotating blade accelerates until thrown out. The thrown projectile forms a certain fan-shaped stream beam, and the impact of the working plane plays a role in cleaning and strengthening. Then the projectile, along with dust and impurities, passes through the rebound chamber to the top of the storage hopper. The high-power dust collector separates the pellets and dust through the separation device above the storage hopper, the pellets enter the storage hopper for recycling, and the dust enters the dust collector through the pipeline. Finally, the machine is cleaned by the air flow of the supporting vacuum cleaner, and the pellets and the impurities are recovered respectively, and the pellets can be recycled.

Humanized control box,

controllable throughout

According to the different conditions of the road surface to set the cleaning speed, steel shot feed, pulse back blowing time period, dust filter cylinder cleaning interval time

DUST REMOVAL LINK PIPE

Dust removal is more standardized and environmentally friendly

|

Product name

|

Road Shot Blasting Machine

|

|

Working width

|

270 mm

|

|

Traveling speed

|

0.5~20 m/min

|

|

Concrete surface cleaning efficiency

|

≥150 M2/h

|

|

Diameter of connecting pipe for dust removal

|

120 mm

|

|

Recommended diameter of steel shot

|

1.2-1.8 mm

|

|

Steel shot consumption

|

100 g/m2

|

|

Matching dust collector

|

Automatic blowback vacuum cleaner

|

one-stop service for customers and provide them with a good user experience.

The company's main business: metal abrasives, standard shot blasting machines; Spare parts for shot blasting machine; Non standard shot blasting machine; Equipped with an executable valve; Laser cutting machine and providing comprehensive metal surface cleaning solutions.

* Since its establishment, the company has actively focused on the development and research of its main products, always adhering to the development concept of "techno-logy leading, customer first", in order to improve the international competitiveness of the enterprise and shape a first-class Jinbaiyi brand.

* The company has a professional technical research and development team that can provide professional technical services for different types of workpieces according to customer requirements. It can also display the surface treatment effect of workpieces through 3D simulation software to achieve customer satisfaction.

* The electrical system equipped with the equipment has advantages such as high effi-ciency, energy conservation, high degree of automation, and friendly human-machine interface.

* Our company has developed an internationally leading remote monitoring and fault diagnosis system, which enables real-time monitoring and fault detection of equipment, enabling early detection and troubleshooting, ensuring efficient operation of equipment.

Q

How to install the machine?

A: Complete equipment of shot blasting machine, Standard equipment can choose remote guided installation. We will arrange 1-2 engineers to guide the installation and assembly of non-standard equipment at your factory.

Q

Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We can provide products such as steel shot, steel sand, steel wire cutting shot, stainless steel shot, and other metal abrasives related to surface cleaning and anti-corrosion.

Q

How long is your delivery time?

A: Generally Standard shot blasting machine 7-20 workdays. Non-Standard Shot blasting machine is 20-60 workdays. Shot peening machine is 30-60 workdays. It is according to quantity and machine model.

Q

What is the shot blasting machine?

A: Shot blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, ship building rail, and many others.

Q

What are your pre-sales and after-sales services?

A: Pre sales services include: consulting products, samples, technical solutions and quota-tions; After sales service includes: 24-hour response, engineers' online guidance, engineers' installation in the customer's factory, and training on how to install and use the product.

Hot Searches