- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1500 KG

-

Application:

-

Automatic feeding machine

-

Material:

-

HDG

-

Power:

-

4.1kw

-

Type:

-

Auger

-

transport pipe:

-

customized

-

feeding pipe:

-

HDG with dia 160

-

Movable:

-

available

-

Driver system:

-

2Engineer

-

Hopper:

-

80*80

-

Delivery:

-

Disassembled

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CONNECT

-

Model Number:

-

MRS-4.5(1802)

-

Weight:

-

1500 KG

-

Application:

-

Automatic feeding machine

-

Material:

-

HDG

-

Power:

-

4.1kw

-

Type:

-

Auger

-

transport pipe:

-

customized

-

feeding pipe:

-

HDG with dia 160

-

Movable:

-

available

-

Driver system:

-

2Engineer

-

Hopper:

-

80*80

-

Delivery:

-

Disassembled

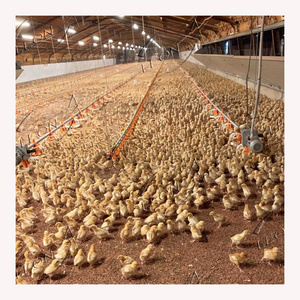

Main feeding line system consists of automatic driving device, a silo, a conveying pipe, an auger and a feed sensor. The main feeding line system is mainly used to convey the feed in the silo into the hopper of the feeding line and automatically control the conveying opening/closing of the motor by the material level sensor to achieve the aim of automatic feeding.

Performance parameters of main feeding line system

1 High-quality special driving reduction motor Power: 0.75kw, voltage: 380V, frequency: 50HZ, three-phase AC current

2 Feeding system Diameter of conveying pipe: φ75*3.6mm, material: PVC Helical spring auger from South Africa, Feeding ability: 1,400kg/h, maximum conveying length: 60m Radius of bending pipe: R1500 (inclination angle: 30 degrees)

3 Material level sensor from Israel: time delay range 0 to 2 hours

Performance parameters of main feeding line system

1 High-quality special driving reduction motor Power: 0.75kw, voltage: 380V, frequency: 50HZ, three-phase AC current

2 Feeding system Diameter of conveying pipe: φ75*3.6mm, material: PVC Helical spring auger from South Africa, Feeding ability: 1,400kg/h, maximum conveying length: 60m Radius of bending pipe: R1500 (inclination angle: 30 degrees)

3 Material level sensor from Israel: time delay range 0 to 2 hours

Product Details

|

SQ

|

capacity(Ton)

|

|

|

(mm)

|

(mm)

|

|

|

|

|

|

1

|

3

|

1.8

|

4.5

|

1

|

1

|

4

|

350

|

1

|

3.5

|

|

2

|

4.5

|

1.8

|

7.5

|

1

|

1

|

4

|

400

|

2

|

4.4

|

|

3

|

6

|

2.45

|

9.5

|

1.2

|

1.2

|

6

|

450

|

1

|

4.7

|

|

4

|

8

|

2.45

|

13.5

|

1.2

|

1.2

|

6

|

500

|

2

|

5.6

|

|

5

|

10

|

2.45

|

17.66

|

1.2

|

1.2

|

6

|

550

|

3

|

6.5

|

|

6

|

15

|

2.75

|

22.5

|

1.2

|

1.2

|

6

|

650

|

3

|

6.5

|

|

7

|

20

|

3.05

|

29

|

1.2

|

1.2

|

6

|

70

|

3

|

7

|

|

8

|

25

|

3.66

|

33.8

|

1.2

|

1.2

|

8

|

950

|

2

|

6.5

|

|

9

|

30

|

3.66

|

43.1

|

1.2

|

1.2

|

8

|

1140

|

3

|

7.4

|

|

10

|

35

|

3.66

|

52.5

|

1.2

|

1.2

|

8

|

1300

|

4

|

8.3

|

Product Category

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

FAQ

1. how many types of chickens can it be processed?

A: It can process broiler ,layers, quails,goose,ducks and pigeon.

2.what is the capacity of this line?

A: We supply slaughter lines from 300bph to 1200bph, and if about 100-200bph, we suggest client to take manual slaugter system(electric scalder, drum plucker), and 300-500bph, you can take our compact slaughter line.

3.can it be process different weight of birds?

A: of course , but all the birds must be in the range of shackles, if the birds weight is too much different , they will drop from shackles, and the shackle distance is different from different birds.

4.Can you design and install the project for us?

A:We have good design and installation department for help you on this project.

5.What is the differences from Manual EV line to Automatic EV line?

A: as you know ,manual EV line is working by labors, and it can work with different weight of birds, but automatic line will only process almost same birds.

6.What is the differences from screw chiller to air chiller?

A: screw chiller is working with cooling water, so if you want the effect is good, you need arrange water chiller and ice flaker for cooling the normal water into cold water, its okay for the country that water is enough. Air chiller is like a cold room, which uses compressor unit and conveying line to make birds moving in the room, then the cold air meet with carcasses.

7.How is Connect Group?

A: Connect Group is a company in China, which have his own trademark, Our group totally have seven

companies, which including one poultry processing equipment manufacture, two rendering equipment manufacture, one broiler equipment plant, one fridge equipment construction plant, one trading company which responsible for marketing and Import and Export, and one Industrial company, we also cooperate with Netherland poultry processing equipment supplier JM to build fully automatic poultry processing plant, which covers the shortage of fully automatic Evisceration and cut-up equipment in China market.

8: Why we select Connect Group?

A:Connect Group is with the best service for the clients..Can you design and install the project for us?

Hot Searches