- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yupack

-

Voltage:

-

220V-480V 3P 50HZ/60HZ

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

150 kg

-

conveyorsize:

-

as customer request

-

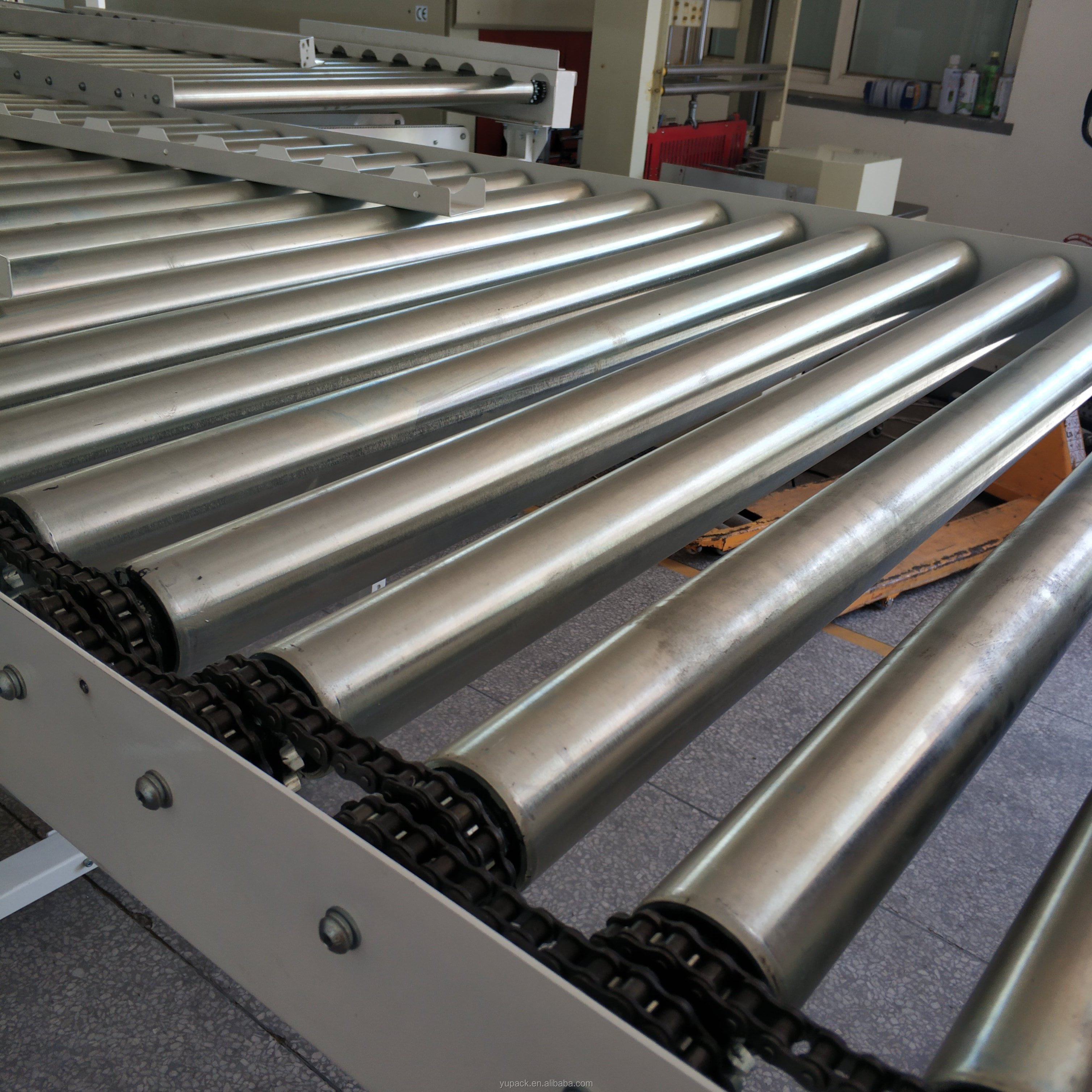

roller diameter:

-

50mm

-

roller material:

-

Galvanized roller/or stainless steel

-

roller drive type:

-

by o shape belt

-

lift&transfer system:

-

come with

-

frame&leg material:

-

carbon steel or stainless steel

-

voltage:

-

220-480V 3P 50/60HZ

-

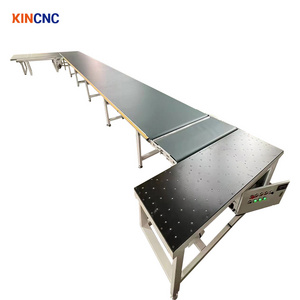

Conveying speed:

-

10m/min or other

Quick Details

-

Power:

-

3KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

900mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yupack

-

Voltage:

-

220V-480V 3P 50HZ/60HZ

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

150 kg

-

conveyorsize:

-

as customer request

-

roller diameter:

-

50mm

-

roller material:

-

Galvanized roller/or stainless steel

-

roller drive type:

-

by o shape belt

-

lift&transfer system:

-

come with

-

frame&leg material:

-

carbon steel or stainless steel

-

voltage:

-

220-480V 3P 50/60HZ

-

Conveying speed:

-

10m/min or other

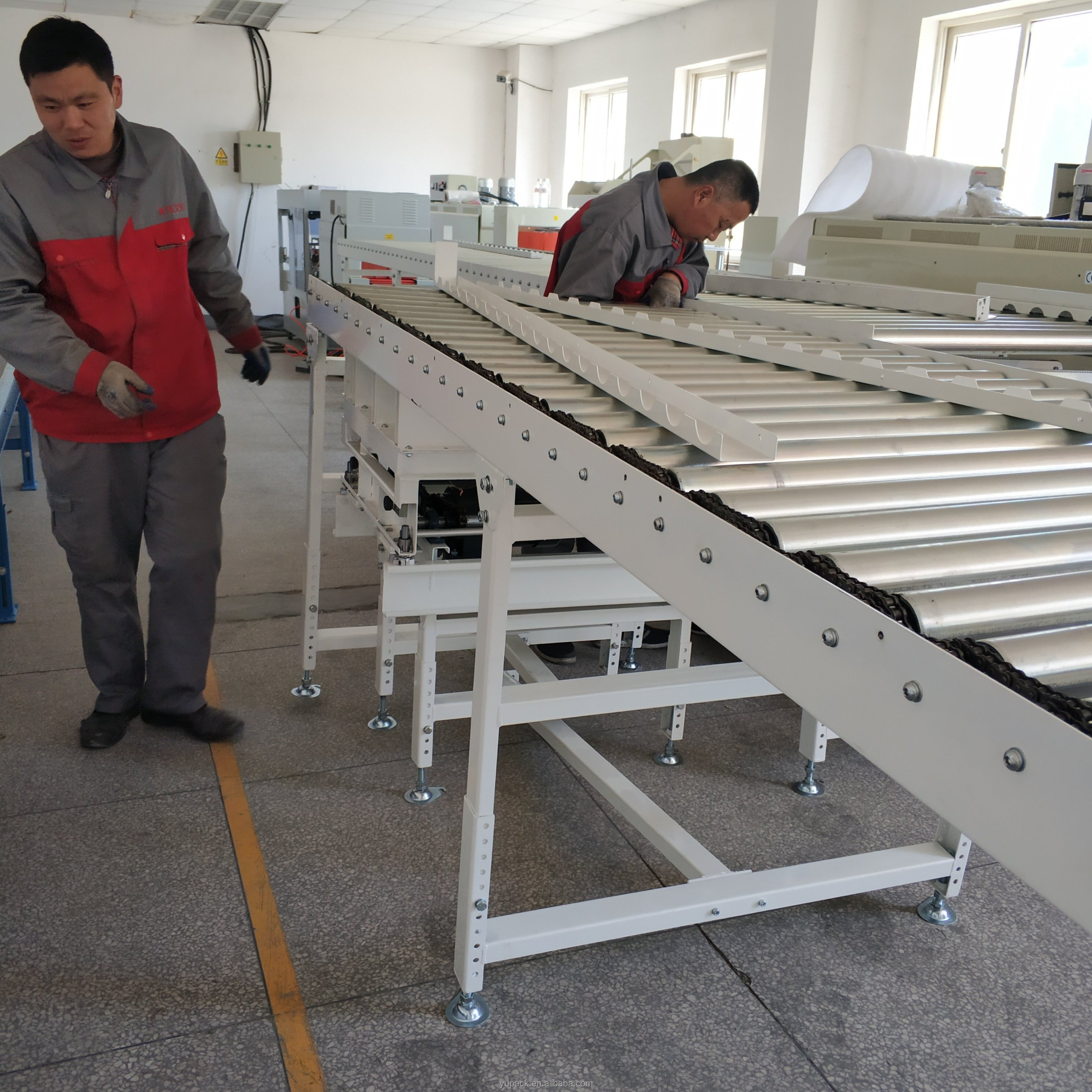

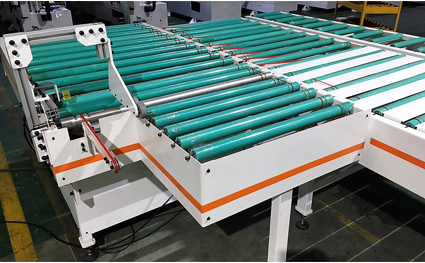

The operating principle of the receiving table with a mechanized raising of all of the round roller belts transferring the part onto rollers gently transferring it 90 degrees to the parallel return conveyor. Once the panels have cleared the receiving table the round roller belts return to their lowered position to receive the next work piece. The pass line between the receiving table and the parallel return is approximately 50mm to avoid interference when oversized panels are traveling in opposite directions.

video link:

https://www.youtube.com/watch?v=kjLbmJfZzo8

Conveyor features:

-Motorized in-feed receiving rollers are extended to parallel the edgebander’s out-feed track.

-Small in-feed roller belt to assist small parts when exiting the edgebander’s out-feed track.

-2 (two) adjustable photo eyes to divert small parts across multiple return rollers.

-Hold down rollers to prevent oversized parts from tipping while being fed onto the receiving table.

-In-feed receiving table ships as 1 (one) complete unit.

-Extended out-feed table comes standard allowing oversized parts to rotate back onto the receiving table.

-Heavy duty welded from construction.

-Heavy duty gear box with chain drive.

-Variable feed speeds, adjustable up to 28m/min. Comes preset at 12, 16 and 20 m/ min for PET edgebanders.

-Oversized heavy duty air cylinders.

-Clean, well-organized control panel design.

-Delta VFD (Variable Frequency Drive).

-Delta PLC (Programmable Logic Controller).

-Voltage: 220V-480V/3PH 50/60HZ

-Min. Part Size: 4” x 12”.

-Max. Part Size: 48” x 48”, without outrigger.

-Max Part Size: 48” x 96”, with outrigger and minimal assistance from operator.

-Optional Widths in 24”, 48”, & 60”, built to order..

We had made the return conveyor for my Mexico customer in Nov,2016.