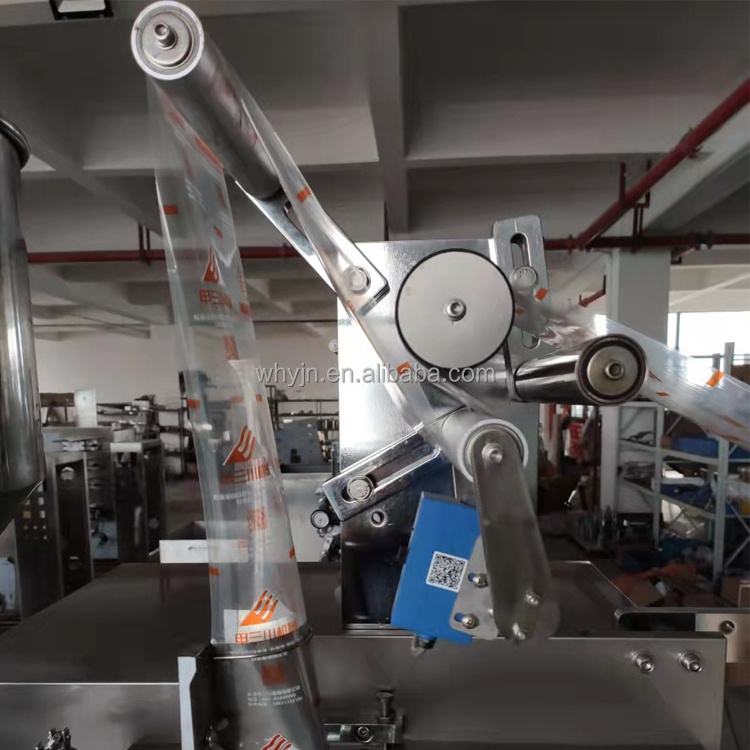

Roll film device.

Thicker film winding device,more stable and smooth filmwinding when starting

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Voltage:

-

380V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YJN

-

Dimension(L*W*H):

-

140*100*180CM

-

Product name:

-

Liquid Sauce Granular Power Pouch Filling Packing Machine

-

After-sales Service Provided:

-

Online Support

-

Keywords:

-

pouch Fillng Sealing Machine

-

Suitable for:

-

Liquid Sauce Granular Power product

-

Material:

-

Stainless Steel 304/316

-

Usage:

-

Paste Cream Sauce Jam Lotion

-

Advantage:

-

Easy Operation High Efficiency

-

Control:

-

PLC+ Touch Screen

-

Processing Types:

-

Automatic Bag Filling Sealing Production Line

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing, Embossing, SLITTING

-

Packaging Type:

-

Bags, Pouch, Sachet

-

Packaging Material:

-

Plastic, film

-

Weight (KG):

-

500

-

Voltage:

-

380V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YJN

-

Dimension(L*W*H):

-

140*100*180CM

-

Product name:

-

Liquid Sauce Granular Power Pouch Filling Packing Machine

-

After-sales Service Provided:

-

Online Support

-

Keywords:

-

pouch Fillng Sealing Machine

-

Suitable for:

-

Liquid Sauce Granular Power product

-

Material:

-

Stainless Steel 304/316

-

Usage:

-

Paste Cream Sauce Jam Lotion

-

Advantage:

-

Easy Operation High Efficiency

-

Control:

-

PLC+ Touch Screen

-

Processing Types:

-

Automatic Bag Filling Sealing Production Line

Products Description

Automatic vertical filling and sealing machine

1.Vertical type automatic high speed packing machine is a three roller vertical packaging machine designed for the

implementation of the viscous or pasty fluid materials

Granular Power Product

automatic packaging, can realize three edges sealing or four edges sealing packing.

2.The whole machine adopts the advanced industrial computer bus design and PLC control system, through the color touch screen to finish all kinds of parameter setting and modification, characteristic of the photoelectric control system can make photoelectric automatic calibration in 2-3 bag cursor position.

3.The seals adopt roller method, solid and reliable.

4.Packing materials injected into packing bags by Hibar pump, high precision, the cut off ways can use each of flat knife, serrated knife, point marking knife.And equipped with with ease open bags cutting device.

Application

The machine is suit for automatic filling and packing liquid/paste/sauce/

Granular /Power Product/

cream item etc.such as milk, juice honey, hair shampoo, tomato paste, g

ranular Poewr Product, Cocoa Coffee power.

salad dressing, jam ect. The machine adopt the pneumatic pump dosing unit which have the machine advantage of suit for viscous liquid item

granular Power

product with high efficient and reliable performance.

Foil Bag Production Line

Product Paramenters

|

parameters

|

Content

|

Remark

|

|

Model

|

LG-GF100

|

|

|

Bag making length:

|

70 〜170mm

|

|

|

Bag making width:

|

40 〜120mm

|

Change the widtli of mechanical packaging, need to change the molding

|

|

Filling capacity

|

10-50ml (g)

|

|

|

Filling accuracy

|

土 (0.1-0.2)g

|

|

|

Packing speed

|

30~120 bags per minute

|

Depending on materials and specifications

|

|

Mechanical Power

|

3KW/AC380V

|

|

|

Mechanical Dimension

|

1660*1100*1960mm

|

|

|

Weight

|

500kg

|

|

|

Packing diameter

|

≤450mm

|

|

|

Diameter of film coil

|

75mm

|

|

|

Filin material

|

PET/AL/PE、PET/PE、 PA/PE

|

|

|

Cut-off mode

|

Flat knife, seirated knife, stippling knife

|

One of three

|

Details Images

The main electrical components of the host like PLC, touch screen, inverter and so are using imported Delta brand.

Touch Screen.

Simple operation

multi-language support.

This Machine can achieve 30 consecutive days of non-stop stable production, design service life of 8-10 years.

The operating signal is stable and the photoelectric tracking response is fast. If the detector is not detected in the two bags, the machine realizes all movement stopping, avoid the waste of packaging materials, materials and labor.Sealing type

for making three-side seal, four-side seal.other bag types can be customizedaccording to customer needs

Hot Searches