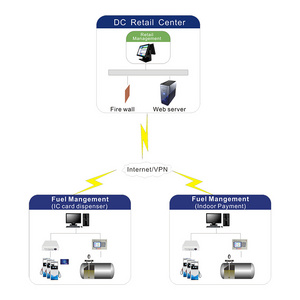

Greenfir provides a proven design, full turnkey package including engineering, manufacturing, installation, commissioning and service & maintenance.

The latest Greenfir technology offers a filling station with maximum accuracy, reliability and safety in combination with a very low boil off rate.