- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

70 r.p.m

-

Width of bed (mm):

-

1600 mm

-

Spindle Motor Power(kW):

-

75

-

Travel (X Axis)(mm):

-

800 mm

-

Travel (Z Axis)(mm):

-

1200 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baishun

-

Model Number:

-

CK5116

-

Voltage:

-

as your request

-

Weight (KG):

-

7500

-

Marketing Type:

-

Other

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Accessory:

-

Diamond Cutting Tools

-

Precision:

-

High Precision

-

Turret Type:

-

Electric Turret

-

Color:

-

Custom-made

-

Keyword:

-

Single Turret CNC vertical Lathe

-

Usage:

-

Metal Parts Machining

-

Processing type:

-

Metal Processing Machine

-

Max. Swing Diameter:

-

2600mm

-

Power(W):

-

30kw

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

800

-

Year:

-

new

-

Max. Spindle Speed (r.p.m):

-

70 r.p.m

-

Width of bed (mm):

-

1600 mm

-

Spindle Motor Power(kW):

-

75

-

Travel (X Axis)(mm):

-

800 mm

-

Travel (Z Axis)(mm):

-

1200 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baishun

-

Model Number:

-

CK5116

-

Voltage:

-

as your request

-

Weight (KG):

-

7500

-

Marketing Type:

-

Other

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Accessory:

-

Diamond Cutting Tools

-

Precision:

-

High Precision

-

Turret Type:

-

Electric Turret

-

Color:

-

Custom-made

-

Keyword:

-

Single Turret CNC vertical Lathe

-

Usage:

-

Metal Parts Machining

-

Processing type:

-

Metal Processing Machine

-

Max. Swing Diameter:

-

2600mm

-

Power(W):

-

30kw

CK5116 Single Turret Type CNC Vertical Lathe 1600mm

A. Product application and features:

1. It is mostly used to process middle-diameter tire mould and flanges, various valves and pipelines, pressure vessels, screw propeller, steamer machine accessories , plastic mould, shafts and other work-piece .

2. It is suitable for processing the internal/external cylindrical surface, conical surface, end face etc

3. Spindle bearings use domestic famous-brand company products.

4. Headstock takes symmetrical structure to make thermal deformation be even, avoiding the spindle center generates offsets.

5. Gears in headstock and guide way are processed by quenching to ensure accurate transmission and high rigidity.

6. Vertical lathe table inlaids with zinc alloy wear-resistant guide guard and can access pressure oil (0.2-0.4MPA) between the rails for improving load-carrying ability of workbench.

7. Vertical lathe casting has passed through strict artificially aged and vibration aging in order to make sure the rigidity and stability of lathe.

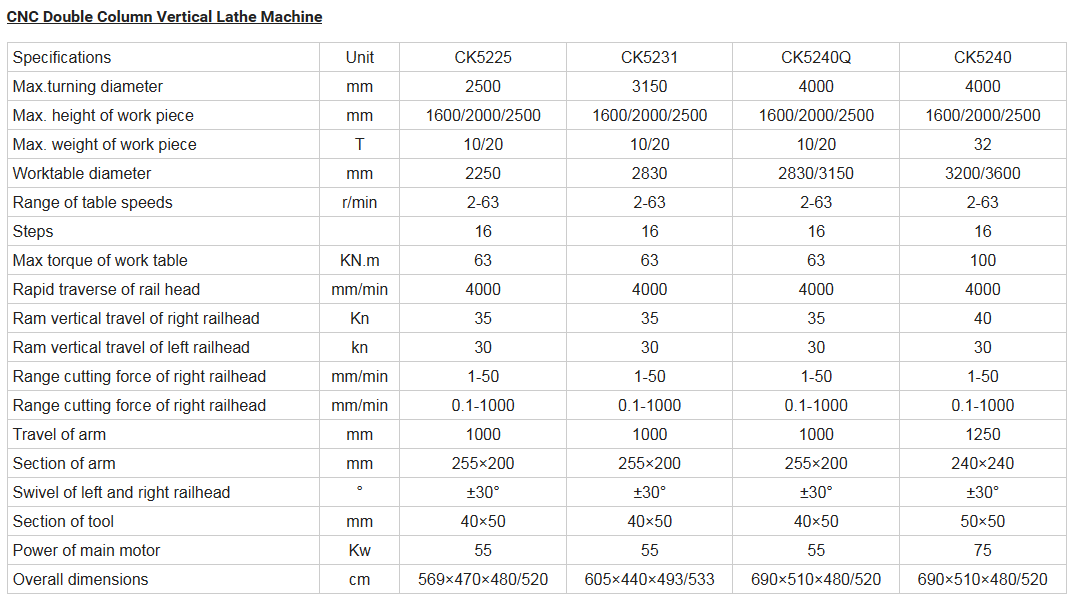

B. Main technical data (Single Turret CNC vertical Lathe ):

| Model | CK518 | CK5112Q | CK5112A | CK5116Q | CK5116A | CK5120A | CK5126A |

| Max. turning diameter of vertical tool rest (mm) | 800 | 1200 | 1200 | 1600 | 1600 | 2000 | 2600 |

| Working table diameter (mm) | 700 | 1000 | 1000 | 1400 | 1400 | 1800 | 2200 |

| Max. height of work-piece (mm) | 800 | 1000 | 1000 | 1200 | 1200 | 1250 | 1400 |

| Max. weight of work-piece (kg) | 1500 | 1500 | 3200 | 3200 | 5000 | 8000 | 8000 |

| Range of worktable rotation speed (rpm) | 30-260 | 20-180 | 6.3-200 | 15-160 | 5-160 | 3.2-100 | 2.2-70 |

| Feeding series | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless |

| Range of tool rest feed (mm/min) | 0.25-90 | 0.25-90 | 0.8-86 | 0.25-90 | 0.8-86 | 0.8-86 | 0.8-86 |

| Cross beam travel (mm) | 500 | 1000 | 650 | 1200 | 650 | 890 | 1090 |

| Horizontal travel of tool rest (mm) | 500 | 700 | 700 | 900 | 916 | 1115 | 1400 |

| Vertical travel of tool rest (mm) | 450 | 500 | 650 | 750 | 800 | 800 | 800 |

| Size of section of cutter bar (mm) | 30*40 | 30*40 | 30*40 | 30*40 | 30*40 | 30*40 | 30*40 |

| Main motor power (kw) | 11 | 15 | 22 | 15 | 30 | 30 | 30 |

C. Machine pictures for your reference:

CK5116 Single Turret Type CNC Vertical Lathe 1600mm

,

,

D. Packing and shipping:

CK5116 Single Turret Type CNC Vertical Lathe 1600mm

Packing: In plastic wrap, wooden case and container or as required;

Shipping: Within 45 days after receving the deposit

Container: Usually 1 piece 20GP container will be okay.

E. Our services:

Pre-Sales Service

Inquiry and consulting support; Sample testing support.; View our Factory.

After-Sales Service

Training how to instal the machine, training how to use the machine ;Engineers available to service machinery overseas.

About warranty period:

During warranty period (one year), if you have any parts broken because of qulity problem,we will supply to you free of charge by express.

Out of warranty period, if you have any question, you can contact us, we will supply our best service to you as usual.

1. Technical support online service provided .

2. Technical files service provided.

3. Machine operation video provided

4. On-site training service provided.

5. Spare parts replacement and repair service provided.

6. All of the questions will be replied within 24 hours

F. Contact us:

1. All kinds of agreement can be signed with your company if you have any afraid for our products;

2. Quality is our culture ;

3. With us your money in safe, your business in safe ;

4. we think our product will give you an edge over your competitors ;

5. 7*24 hours multi-language professional after-sales service group .