- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZCX

-

Voltage:

-

380V, 380V

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Suitable material:

-

Solid silicone

-

Product Type:

-

Silicone tube

-

Screw Rod Material:

-

9Cr18MoV

-

Screw L/D:

-

12:1

-

Capacity:

-

About 65KG/H

-

Curing oven material:

-

Stainless steel

-

Conveyor belt:

-

Stainless steel

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

12:1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZCX

-

Voltage:

-

380V, 380V

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Suitable material:

-

Solid silicone

-

Product Type:

-

Silicone tube

-

Screw Rod Material:

-

9Cr18MoV

-

Screw L/D:

-

12:1

-

Capacity:

-

About 65KG/H

-

Curing oven material:

-

Stainless steel

-

Conveyor belt:

-

Stainless steel

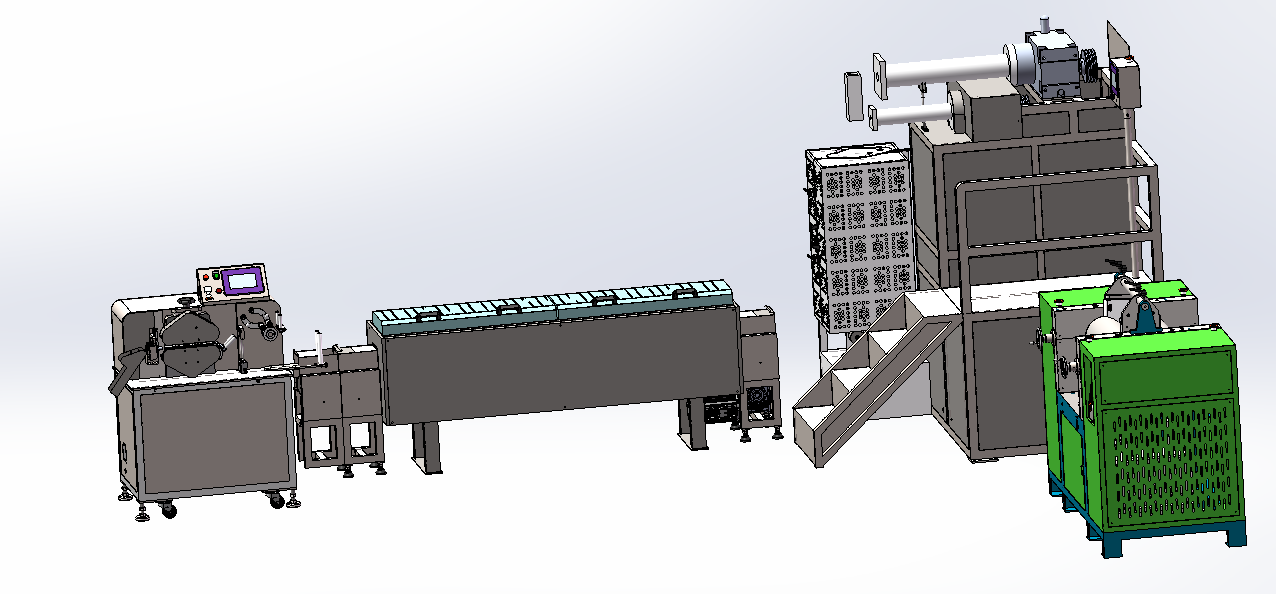

OEM ODM custom shape soft silicone infusion hose catheter medical tube extrusion line solid silicone medical tube extrusion

Configuration

|

P/N |

Model |

Q’ty |

Unit |

|

Vertical Extruder |

ZCX-CJC-3050L |

1 |

Set |

|

Vertical High Temperature Shaping Furnace |

ZCX-HW1000-600L

|

1 |

Set |

|

Chain Tunnel Furnace |

ZCX-HW2000-350W |

3 |

Pcs |

|

High Precision Servo Tube Cutting Machine |

ZCX-QGJ-120 |

1 |

Set |

|

Silicone Mixing Machine |

ZCX-KLJ-9C |

1 |

Set |

This production line mainly produces medical silicone tubes. Such as the infusion tube, catheter, drainage tubes.

The thickness, shape of the silicone layer can be customized accordingly to users’ and optical requirements.

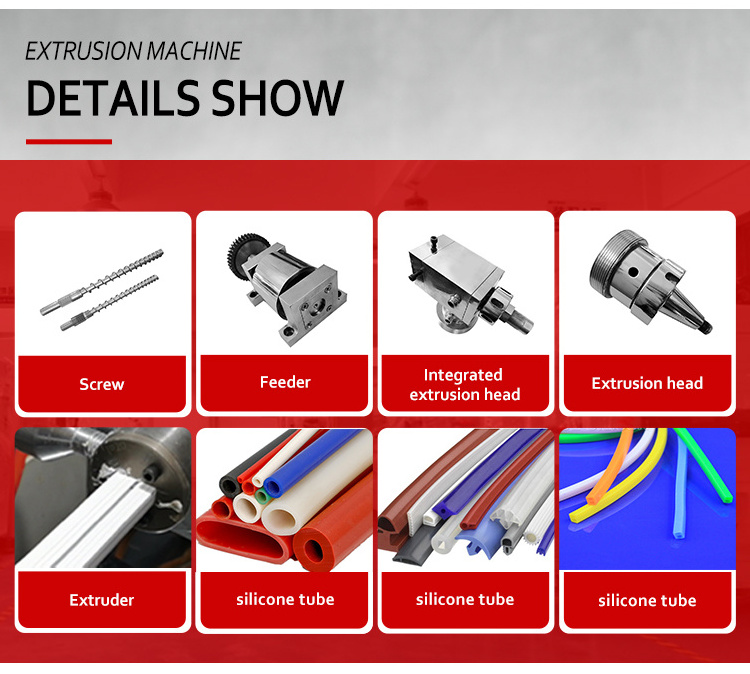

Features:

1.Screw stem and screw cylinder material:Dual alloy centrifugal casting is used in the extruder barrel bore,thickness≥2mm,screw stem material 9Cr18MoV,tempering and hardening process;High hardness, high wear resistance, lead-free, halogen-free, meet the medical requirements.

2.Extruder head, rubber feeding port and screw stem can be easily disassembled and cleaned,convenient to maintenance and overhaul.

3.Used Fuji and Siemens variable frequency speed control system, which runs smoothly and has low noise.

4. According to the different shape of the product, can change the mould optionally and easily replace the product.

5. All parts in contact with the product are transported or isolated by SUS304 and Teflon to ensure that the product is not polluted.

6. The whole set of equipment adopts with visual and touch screen control, supporting functions of over-current, over-voltage, leakage, over-temperature alarm and protection. The product is much safer to use.

7. Closed-loop control system is adopted in the whole production line, which can automatically detect the extrusion speed and pipe cutting speed, so as to realize automatic matching and ensure the shape and size of the product.