- Product Details

- {{item.text}}

Quick Details

-

Features:

-

High Efficiency Low Cost

-

Production Capacity:

-

300-700kg/h

-

Dimension(L*W*H):

-

Customized

-

Voltage:

-

Customized

-

Marketing Type:

-

Biomass Dryer

-

Weight:

-

1000 KG

-

Product name:

-

Dryer Machine

-

Keywords:

-

Biomass Drying Euipment

-

Heating source:

-

Wood gas oil

-

Raw material:

-

Wood Sawdust Rice Husk

-

Drying material:

-

Biomass Particle

-

Product Type:

-

Air Flow Drying System

-

Usage:

-

Drying Wet Materials

-

Dryig process:

-

Hot Air Dry

-

Final product:

-

biomass press pellets

-

Installation:

-

Engineer's Guidance

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Smartech

-

Application:

-

PELLET SAWDUST DRYING

-

Features:

-

High Efficiency Low Cost

-

Production Capacity:

-

300-700kg/h

-

Dimension(L*W*H):

-

Customized

-

Voltage:

-

Customized

-

Marketing Type:

-

Biomass Dryer

-

Weight:

-

1000 KG

-

Product name:

-

Dryer Machine

-

Keywords:

-

Biomass Drying Euipment

-

Heating source:

-

Wood gas oil

-

Raw material:

-

Wood Sawdust Rice Husk

-

Drying material:

-

Biomass Particle

-

Product Type:

-

Air Flow Drying System

-

Usage:

-

Drying Wet Materials

-

Dryig process:

-

Hot Air Dry

-

Final product:

-

biomass press pellets

-

Installation:

-

Engineer's Guidance

Production Description

Wood Shave Chips Sawdust Drying Flash Wood Dryer Machine CE Approved Hot Airflow Rotary Dryer Machine

The Sawdust Pipe Dryer also called pipe dryer,sawdust flash dryer ,this machine is designed for drying material like sawdust,wood shaving,wheat,straw,and corn talks. paddy straw, etc. The diameter of the raw material should be lower than 3mm,and the moisture in the raw materials of less than 40% can be drying one time to meet the requirement for wood briquette production line.

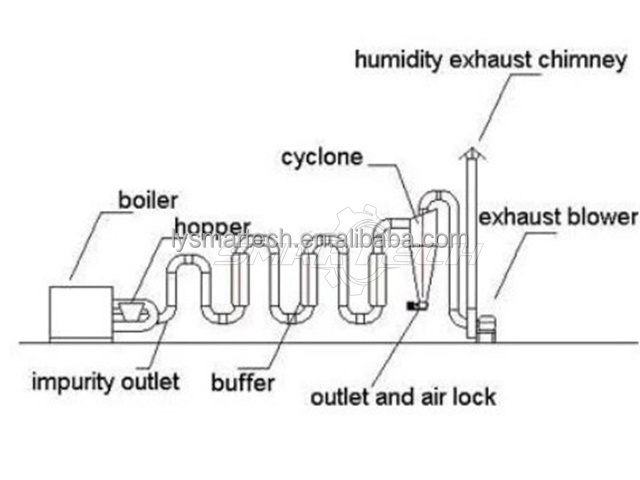

Working principle

The raw material enters the furnace through the pipe through the inlet, and is drawn into the Sakron by the fan along with the hot air around the pipe. The dried materials are released from the Sakron, and waste heat and water vapor are discharged from the Sakron.

Biomass Dryer Features:

1-Suitable for drying materials of moisture 20-70%.

2-Suitable for drying materials like sawdust, rice hull, milling wheat straw, corn stalks etc.

3-Equipped with two fuel boilers, inlet, steel pipe, exhaust blower (fan), air lock and cyclone. Wet materials are input into the hopper.

2-Suitable for drying materials like sawdust, rice hull, milling wheat straw, corn stalks etc.

3-Equipped with two fuel boilers, inlet, steel pipe, exhaust blower (fan), air lock and cyclone. Wet materials are input into the hopper.

4-The fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhaust blower (fan) quickly. And then hot air is flowing and going though the curving pipes and buffer (drying chamber) of dryer, thus wet materials is finished to dry, and the dried materials are discharged from the outlet with air lock.

5- It reduces the moisture to 8-12%.

5- It reduces the moisture to 8-12%.

6- Clients can change the angle of dryer base on the production field.

The nature of the air dryer:

1-After the installation is complete, turn on the fan, check the direction of the fan rotation and whether the suction port is

normal.

2- Check the flange interface to see if it leaks.

3- Bundle the bags that are open at both ends at the lower opening of the separator.

4- Add the material to be dried at the feeding port, and remove the large particles before drying, which is beneficial to increase the drying speed.

5-Add fuel to the furnace to ignite and turn on the fan. When the temperature at the wind outlet is as high as 150 °C, the

material is cut off and dried.

6- Remove large pieces of material from the slag discharge port in time to facilitate feeding.

normal.

2- Check the flange interface to see if it leaks.

3- Bundle the bags that are open at both ends at the lower opening of the separator.

4- Add the material to be dried at the feeding port, and remove the large particles before drying, which is beneficial to increase the drying speed.

5-Add fuel to the furnace to ignite and turn on the fan. When the temperature at the wind outlet is as high as 150 °C, the

material is cut off and dried.

6- Remove large pieces of material from the slag discharge port in time to facilitate feeding.

Specification

|

Product

|

wood sawdust hot rotary Airflow pipe dryer CE approved drying machine price biomass dryer

|

3

|

|

|

Model

|

THG- 219

|

THG - 325

|

|

|

Initial Moisture

|

25%-40%

|

25%-40%

|

|

|

Final Moisture

|

10%-15%

|

10%-15%

|

|

|

Main Power

|

4 kw

|

7.5 kw

|

|

|

Drying Speed

|

200-250 kg/h

|

300-400 kg/h

|

|

|

Pipe Diameter

|

219mm

|

325mm

|

|

|

Cyclone Diameter

|

780mm

|

900mm

|

|

|

Fuel Consumption

|

40-50kg/h

|

60-80kg/h

|

|

|

Dimension

|

10*2.5*3.1 m

|

12*2.5*3.2 m

|

|

|

Weight

|

1250 kg

|

1580 kg

|

|

Hot AirFlow Wood Biomass dryer:

Wood sawdust dryer machine is the latest drying equipment which our company have (has) studied successfully. It can dry the materials mainly using the hot wind produced by the hot blast stove, the machine is applied to the material in dispersed state which contains high moisture humidity, such as the saw dust, grain or straw.

Products Application

Sawdust Dryer dryer can be used to dry biomass materials (sawdust, crop stalks, leaves, grass,etc.), agricultural products (corn straw, soybean straw, cotton stalks, wheat straw, etC.), chemical products (such as ferilizer, metal powder, sugar), mining industry products (ore, sand, clay, etC.), etc.

Related Products

About Us

Contact Us

Hot Searches