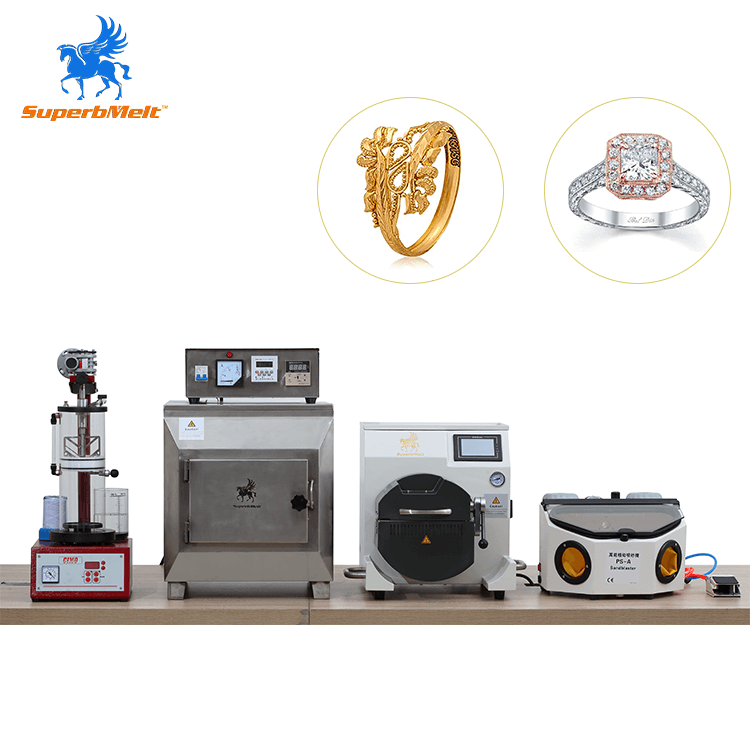

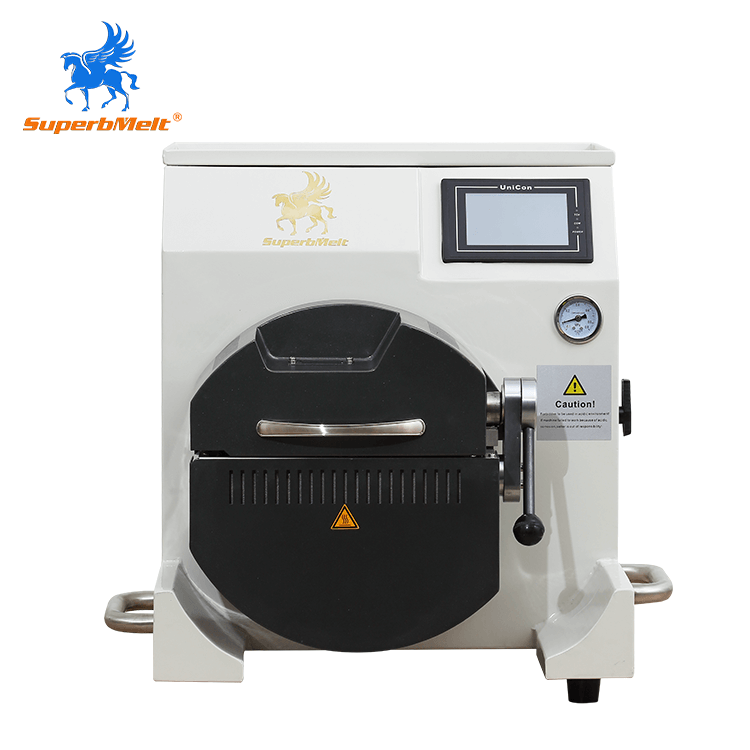

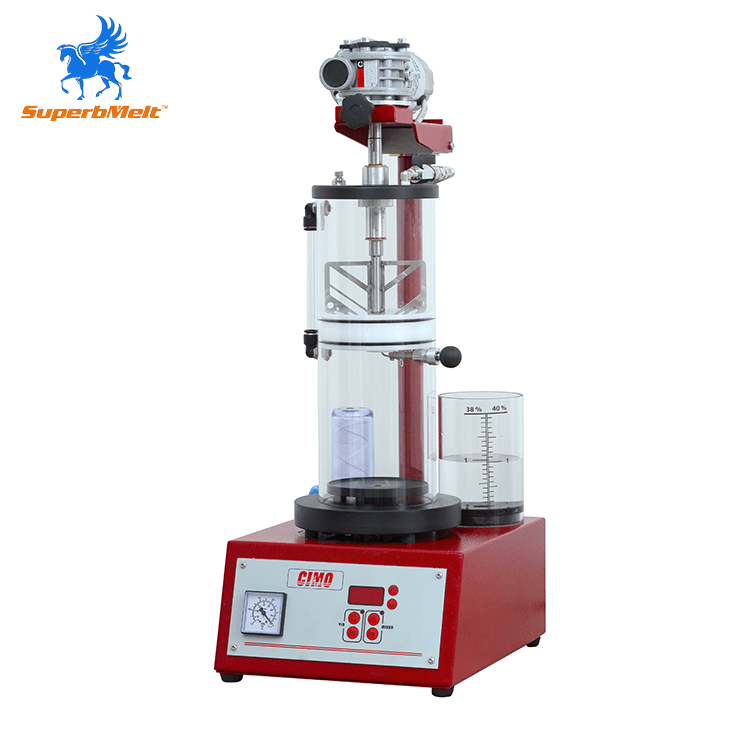

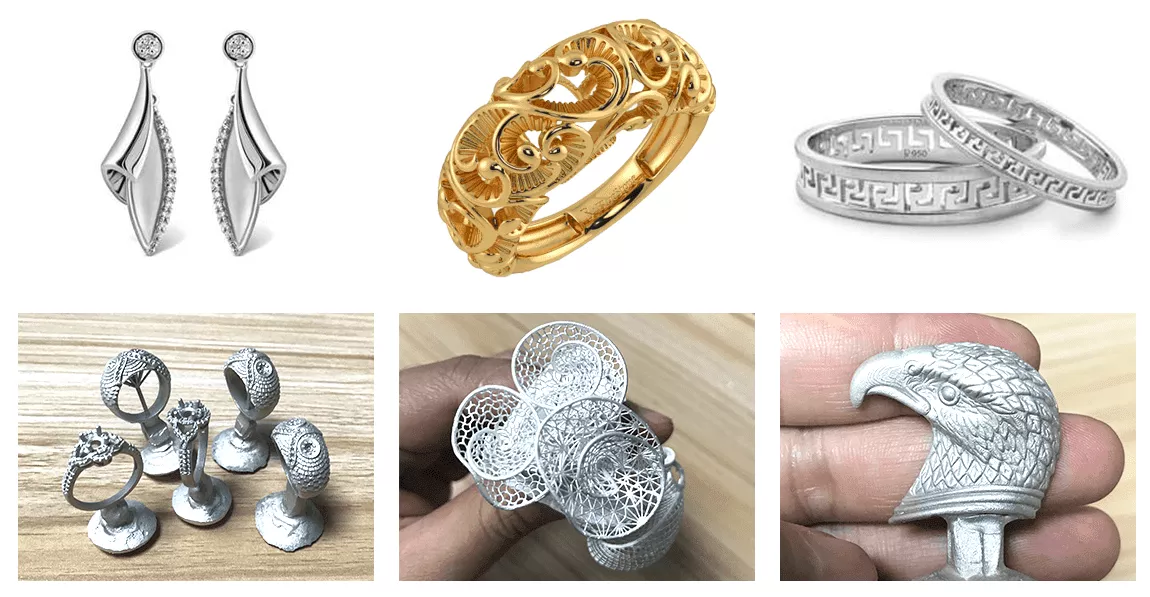

2.Our mission is to build the most innovative melting and casting equipment for jewelry and

precious metal manufacturing, providing you with the highest reliability in your daily operations that guarantees the best quality.

3. As a leading precious metal melting and casting solutions provider, the provision of timely technical support for our manufacturers is an essential part of our services. With a strong technical support team that comprises of qualified and well trained (in China) local technicians, we are committed to solving any problems that you may have.