- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PT

-

Voltage:

-

Based on Local

-

Power:

-

7KW

-

Dimension(L*W*H):

-

1100x1700x1200mm

-

Weight (KG):

-

500

-

Dimension:

-

1100x1700x1200mm

-

Model:

-

GP-881

-

Temperature:

-

RT~ 200°C

-

Diameter of outer cylinder:

-

700*560(mm)

-

Rolling speed:

-

0-50r/min

-

Spray guns:

-

Adjustable flow, air pressure and angle

-

Heating power:

-

7KW

-

Weight:

-

300kg

-

Color:

-

Blue

-

Usage:

-

Liquid painting

Quick Details

-

Machine Type:

-

Vibratory Unit, Coating Equipment

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

PCB

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PT

-

Voltage:

-

Based on Local

-

Power:

-

7KW

-

Dimension(L*W*H):

-

1100x1700x1200mm

-

Weight (KG):

-

500

-

Dimension:

-

1100x1700x1200mm

-

Model:

-

GP-881

-

Temperature:

-

RT~ 200°C

-

Diameter of outer cylinder:

-

700*560(mm)

-

Rolling speed:

-

0-50r/min

-

Spray guns:

-

Adjustable flow, air pressure and angle

-

Heating power:

-

7KW

-

Weight:

-

300kg

-

Color:

-

Blue

-

Usage:

-

Liquid painting

Product Description

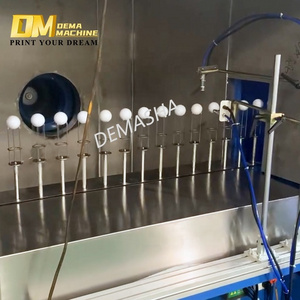

Epoxy Paint Common Vertical Slider Steel Drum Barrel Type Spray Painting Coating Machine For Eyelet Screw Beads Metal Ball

Applicable industries of automatic spraying machine Spraying process for plastic accessories, toy accessories, electronic

accessories, hardware accessories and other industries.

accessories, hardware accessories and other industries.

1. Decorative spraying: used for the decoration of fishing hooks, springs,buttons, nuts, furniture handles, bottle caps and other small parts.

2. Anti-corrosion spraying: used for surface anti-corrosion of small parts such as screws and small nails.

3. Spraying to improve sliding performance: used for spraying of O-ring water-based lubricating coating and PTFE lubricating coating.

4. Spraying of adhesive: used for spraying of oil seal frame, automobile shock absorber bushing frame, brake seal ring and engine seal ring.

5. Spraying on electrical insulation: It is used for spraying insulating coatings such as soft iron core, hard iron core and annular iron core.

Feature

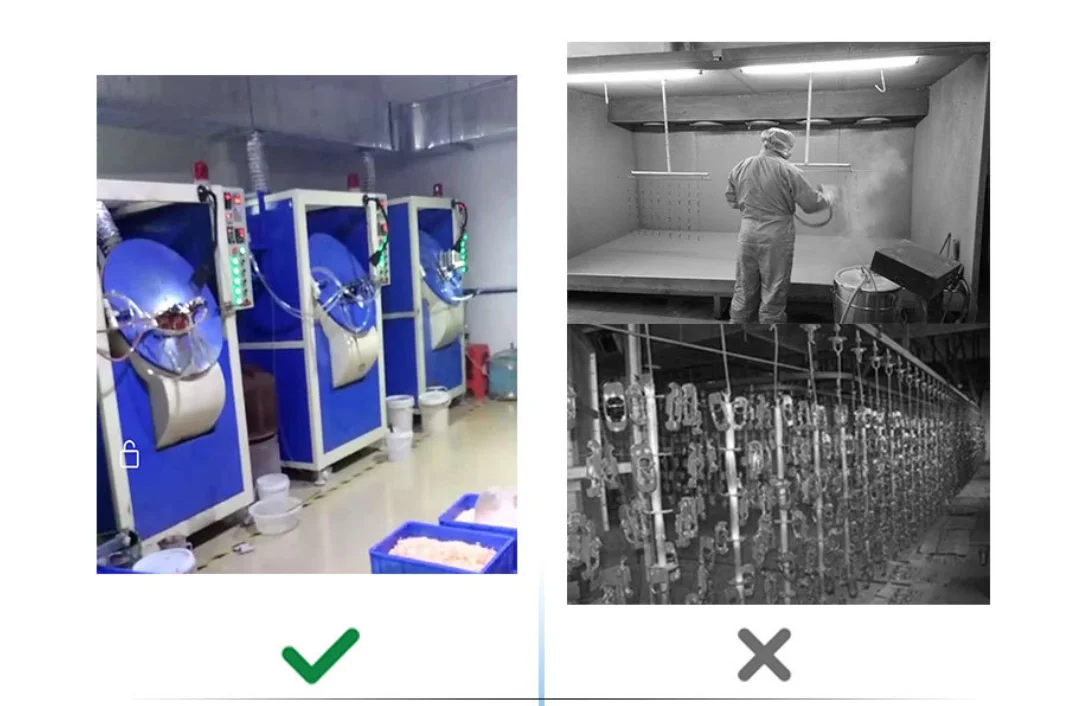

✅

High efficiency: The automatic spraying machine is an automated production that can spray 24 hours a day and has a stable production speed.

✅Stable quality: The automatic spraying equipment produces according to the set parameters when spraying, and the quality is stable.

✅Environmental protection: Automatic spraying equipment greatly reduces environmental pollution and improves the working environment of workers.

✅Reducing costs: Automatic spraying equipment can save more labor costs, with low labor costs.

❌Low efficiency: Hanging workpieces is troublesome, time-consuming and labor-intensive, and requires high technical skills for spraying workers, resulting in low output.

❌Unstable quality: Affected by the skills and status of workers, the quality of sprayed products is unstable.

❌Not environmentally friendly: Harmful gases will be emitted during spraying, polluting the environment and causing great harm to spraying workers.

❌High cost: high labor cost and difficulty in recruiting workers. It requires many more workers than automatic spraying equipment,and the labor cost is huge.

Products details

The products adopt imported technology and core components, with high precision and more perfect details. A strict quality management and assurance system has been established for all products, from raw material procurement to production and manufacturing to delivery and transportation, to ensure that each of the company's products has consistently high quality.

The equipment has advanced technology and a very high paint utilization rate. It uses more than 70% less paint than traditional spray painting. The machine body occupies a small area. The emissions of one hundred units of equipment are less than 20,000m³/h,achieving cost and emission reductions,better protecting people and the environment.

Simple human-machine operation interface,personalized setting of function parameters, and one-click operation of the spraying process. Safe, smart and easy to operate.

The equipment has reasonable structure, advanced technology, stable performance, and intelligent automated operation.

The product coating is made smooth, uniform, dense and scratch-free, which greatly ensures the surface effect and coating performance.

Samples

Accessory List

Specifications

|

No.

|

Item

|

Parameter

|

|

1

|

Model

|

GP-881

|

|

2

|

Diameter of outer cylinder

|

700*560(mm)

|

|

3

|

Heating power

|

7kw

|

|

4

|

Temperature

|

RT~ 200°C

|

|

5

|

Machine size

|

1100x1700x1200mm

|

|

6

|

Rolling speed

|

0-50r/min

|

Packing & shipping

|

packing

|

|

|

size

|

600x600x1100mm

|

|

weight

|

150kg

|

|

Packing Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

|

|

|

|

|

Hot Searches