- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BOSEN

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

850x600x1300mm

-

Power (kW):

-

4

-

Weight (T):

-

0.3

-

Color:

-

BLUE

-

Application:

-

plastic film recycle production

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Shaft Design:

-

Single

-

Weight:

-

300kg

-

Certification:

-

CE ISO

-

Capacity:

-

60-100kg/h

-

Power:

-

4kw,4kw

Quick Details

-

Max.Production Capacity (kg/h):

-

100kg/h

-

Place of Origin:

-

Zhejiang, China

-

Production Capacity (kg/h):

-

60 - 100 kg/h

-

Brand Name:

-

BOSEN

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

850x600x1300mm

-

Power (kW):

-

4

-

Weight (T):

-

0.3

-

Color:

-

BLUE

-

Application:

-

plastic film recycle production

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Shaft Design:

-

Single

-

Weight:

-

300kg

-

Certification:

-

CE ISO

-

Capacity:

-

60-100kg/h

-

Power:

-

4kw,4kw

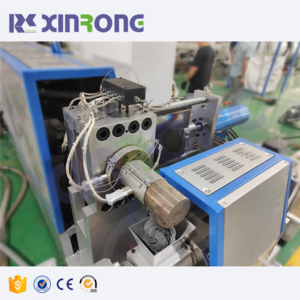

Recycle HDPE LDPE PP ABS PE Plastic Film Grind Crusher Machine

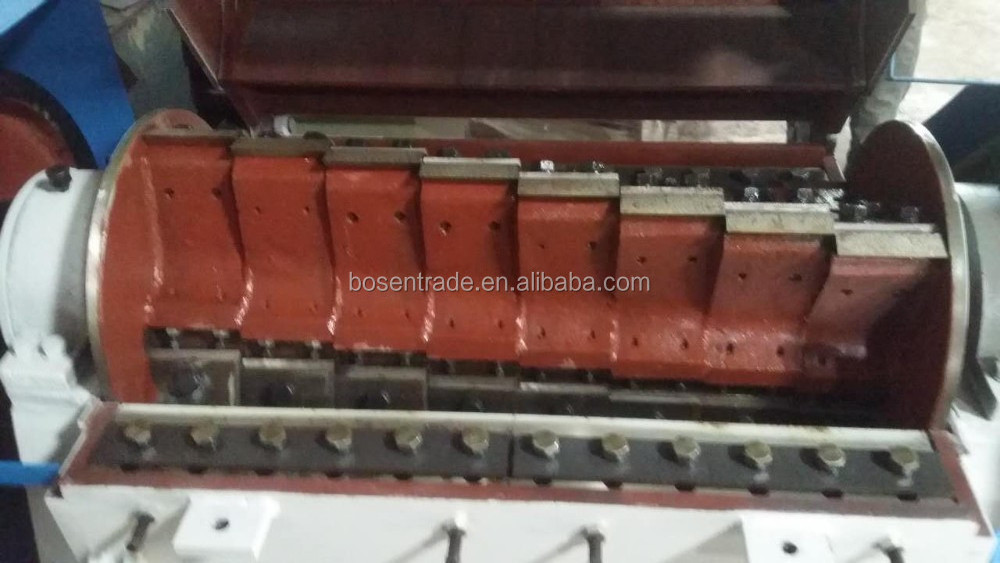

For crushing waste silk, waste film scrap recycling, crushed material diameter can replace the filter can be different depending on your requirements。

We have different size and different ouput type for your choice.

|

Type

|

Output

|

Mouth size

|

Knives quantity

|

Motor

|

Machine size

|

|

F1

|

60-100kg/h

|

250x200mm

|

5pcs

|

4kw

|

850x600x1300

|

|

F2

|

120-200kg/h

|

400x300mm

|

5pcs

|

7.5kw

|

1000x750x1400

|

|

F3

|

200-280kg/h

|

500x350mm

|

8pc

|

11kw

|

1500x900x1700

|

|

F4

|

250-350kg/h

|

650x400mm

|

10pcs

|

15kw

|

1700x1200x1800

|

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.