- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HIGOAL

-

Model Number:

-

PANEL

-

Surface Treatment:

-

GEL COAT

-

application:

-

caravan, truck, RV, trailer walling

-

max width:

-

2750mm

-

length:

-

customized

-

Thickness:

-

1.2mm to 3mm

-

Color:

-

White and others

-

Advantage:

-

Higher Strength Light Weight

-

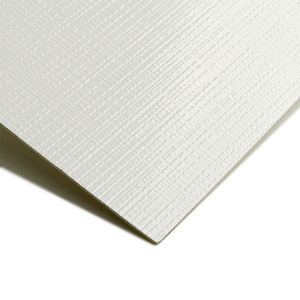

Surface:

-

300um Gel coat

-

Material:

-

Fiberglass Reinforced Polymer ( GFRP)

-

Approval test standards:

-

ISO, ROHS, SGS

-

Using temperature:

-

-38 ~ 110 degree

Quick Details

-

Application:

-

Fiberglass panels for trailers

-

Technique:

-

ROLLING

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HIGOAL

-

Model Number:

-

PANEL

-

Surface Treatment:

-

GEL COAT

-

application:

-

caravan, truck, RV, trailer walling

-

max width:

-

2750mm

-

length:

-

customized

-

Thickness:

-

1.2mm to 3mm

-

Color:

-

White and others

-

Advantage:

-

Higher Strength Light Weight

-

Surface:

-

300um Gel coat

-

Material:

-

Fiberglass Reinforced Polymer ( GFRP)

-

Approval test standards:

-

ISO, ROHS, SGS

-

Using temperature:

-

-38 ~ 110 degree

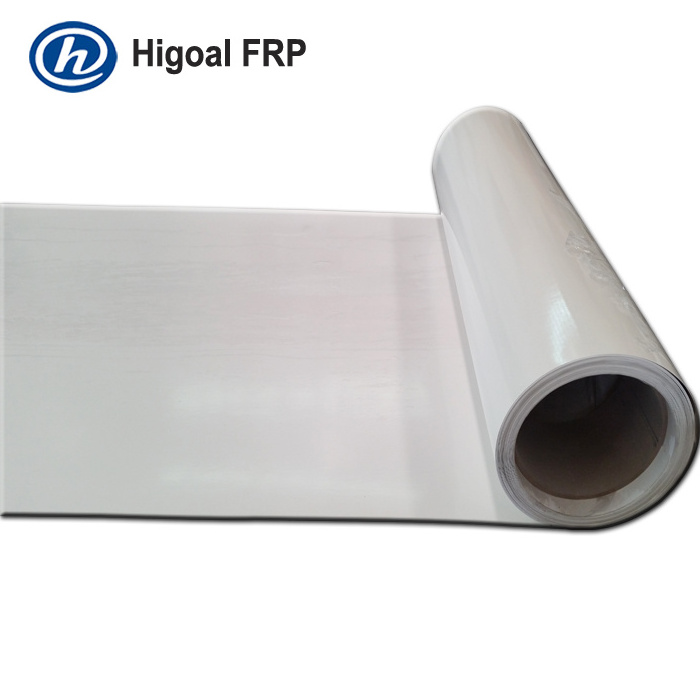

Higoal FRP Fiberglass Panel features:

1) Machine continuously made flat panels,

no limit on length

;

2)

Anti-impact

: much better stiffness and strength than plastic, due to fiberglass reinforced;

3)

Fire resistant

: made by thermosetting resin;

4)

Mildew resistant:

Effectively inhibit the growth of mildew;

5)

Easy install

: No other tools are needed except for rivet or glue only;

6)

Anti-corrosive

: stay good condition immerged into 10% Hydrochloric acid or 3% NAOH solvent for long time;

7)

Easy cleaning

: It can be easy cleaned by steam or high-pressured squirt gun;

8) Extreme

temperature resistant

: Withstand temperature at -40 -110 degree C for long time;

9) Rolled up by machine with 50-100m length as a coil, to

save shipping cost

.

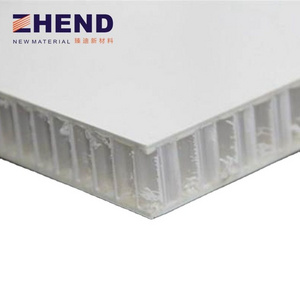

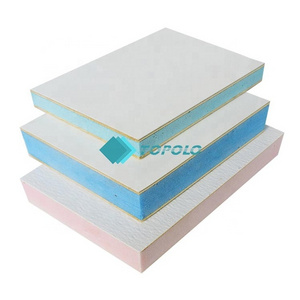

The above mentioned panels can be combined with the froth, gypsum, polywood, aluminium, PP, XPS, honeycomb ,the lsandwich panels is a more strengthen, better rigidity panel, sandwich panels will be easier to install, the installation efficiency will be improved greatly, furthermore, the requirement of wall coarseness will be reduced also.

|

Items

|

Performance

|

|

|

||

|

Material

|

Gel coating: 300um ISO-phthalic polyester gel coat

Matrix resin: unsaturated polyester resin Reinforce fiber: E-glass |

|

|

||

|

FRP panel size

|

Thickness: 1.0mm-3.0mm

Width: ≤2750mm ; Length: customer length |

|

|

||

|

Tensile strength

|

≥75MPa

|

|

|

||

|

Tensile modulus

|

≥4800MPa

|

|

|

||

|

Bending strength

|

≥120MPa

|

|

|

||

|

Bending modulus

|

≥5GPa

|

|

|

||

|

Impact strength

|

≥35KJ/m2

|

|

|

||

|

Compression strength

|

≥35MPa

|

|

|

||

|

Distortion temperature(1.8MPa)

|

>230℃

|

|

|

||

|

Thermal expansivity

|

2.4×10-5℃-1

|

|

|

||

|

Gravity

|

1.6-1.7g/cm3

|

|

|

||

|

Water Absorption

|

0.16%/24hrs, 25C

|

|

|

||

|

Stickiness

|

≥42dyne

|

|

|

||

|

Approval test standards:

|

ASTM-E84, RoHS 2002/95/EC

|

|

|

||

|

Chemical resistance

|

Can be used in foggy environment of 10% HCl and 3% NaOH solvent for long. For usage in other solvent, please contact our engineer.

|

|

|

||

|

UV resistant and impact resistant FRP panels for trailer camper RV body

|

|

|

|

|||

|

Packing

|

1. Protected by stretch film;

|

|

|

|||

|

|

2. Fasten by packing banding and packed on pallet;

|

|

|

|||

|

|

3. Grating corners are protected by FRP angle or thick papercard.

|

|

|

|||

|

Delivery

|

1. Stock grating: 3-5 working days.

|

|

|

|||

|

|

2. Manufacturing: 1-2 weeks, or depends on the order quantity.

|

|

|

|||

Higoal Fiberglass Manufacturer

Higoal FRP Plant

Engineering Support

.