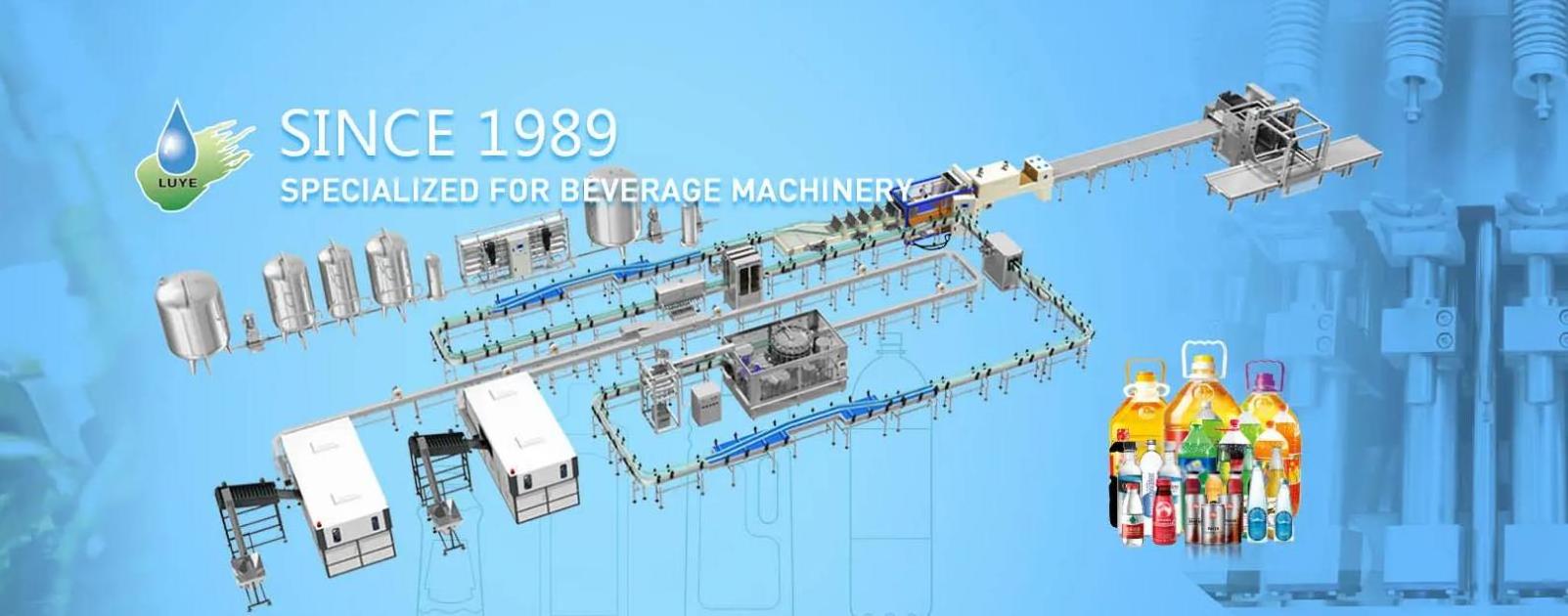

LUYE More than

30

years Professional Manufacturer of Turn-key Beverage Machinery.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

According to Customer requests

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LUYE

-

Dimension(L*W*H):

-

By Model

-

Weight:

-

3000 KG

-

Supply:

-

water filling machinery plant

-

Name:

-

water bottle filling machine

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

SUS304/316(Meet GMP Standard)

-

Filling volume:

-

200ml-2000ml

-

Structure:

-

Rotary 3 in 1

-

Filling precision:

-

within 2mm

-

Product:

-

bottle filling machine

-

Product Keywords:

-

water filling equipment

-

Advantage:

-

20 Years Experiences

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water

-

Filling Accuracy:

-

99%

-

Voltage:

-

According to Customer requests

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LUYE

-

Dimension(L*W*H):

-

By Model

-

Weight:

-

3000 KG

-

Supply:

-

water filling machinery plant

-

Name:

-

water bottle filling machine

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

SUS304/316(Meet GMP Standard)

-

Filling volume:

-

200ml-2000ml

-

Structure:

-

Rotary 3 in 1

-

Filling precision:

-

within 2mm

-

Product:

-

bottle filling machine

-

Product Keywords:

-

water filling equipment

-

Advantage:

-

20 Years Experiences

SINCE 1989

Own water factory

Success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety and cost optimisation. Whether you're producing still or sparkling water, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

With over 30 years experience in designing and implementing customized complete PET line solutions for water, we can help you reach your production targets. Over the years, we have significantly reduced the weight of water bottles while retaining their durability and expanding design opportunities.

Our company also have our owned drinking water plant with 5 complete production lines, all using our own factory machines, if you have interest in it, you are welcome to visit our owned drinking water factory.

With over 30 years experience in designing and implementing customized complete PET line solutions for water, we can help you reach your production targets. Over the years, we have significantly reduced the weight of water bottles while retaining their durability and expanding design opportunities.

Our company also have our owned drinking water plant with 5 complete production lines, all using our own factory machines, if you have interest in it, you are welcome to visit our owned drinking water factory.

Machine Description

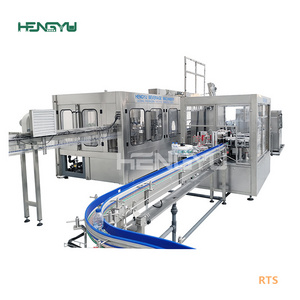

LUYE Water Bottle Filling Machine [ Washing Filling Capping 3 in 1 type ]

Product Application

: This washing filling capping machine is mainly used for Non-aerated carbon dioxide drink, such as mineral water, pure water and so on.The machine design is shorten the time for the drink material contact with outside, Increase the sanitation condition throughout economy benefit.

Capability Character

: It adopts hanging type conveying-bottle structure to make changing bottle model more convenient, faster and easier. The main machine adopts advanced PLC control technology. The key electric elements adopt international famous products.

Advantages

:

1-Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2-Optimum uptime: 30 % reduction in changeover and maintenance downtime

3-Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4-Hygiene improvement through volume control and contactless filling

5-Automatic dummy bottles: Safer, easier cleaning procedures

6-Automatic bottle changeover improves uptime Advantage:

-PLC and Touch screen full automatic control. Easy for operate

-Fastly different bottle size replacement

-Concise structure, reliable and durable, easy to maintain.

1-Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2-Optimum uptime: 30 % reduction in changeover and maintenance downtime

3-Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4-Hygiene improvement through volume control and contactless filling

5-Automatic dummy bottles: Safer, easier cleaning procedures

6-Automatic bottle changeover improves uptime Advantage:

-PLC and Touch screen full automatic control. Easy for operate

-Fastly different bottle size replacement

-Concise structure, reliable and durable, easy to maintain.

Washing part

Into bottle way is air conveyor direct connection with bottle dial.All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.304/316 stainless steel washing pump make the machine more durable.

Filling part

Mainly composes of bottling barrel, bottling valve, guide rail, lifting device, bottle clamping lift device etc.

Bottle is conveyed to the bottling machine with the clamp plate of starwheel drive IV, bottling bottle clamp plate supports the bottle neck and rotates together with the bottling, and ascend along the guide rail and then open the bottling valve for bottling,after finishing bottling, it descend and loose the bottling valve, bottling valve may automatically close. Bottle is discharged from the bottling machine along the clamp plate of starwheel drive V.

Bottle is conveyed to the bottling machine with the clamp plate of starwheel drive IV, bottling bottle clamp plate supports the bottle neck and rotates together with the bottling, and ascend along the guide rail and then open the bottling valve for bottling,after finishing bottling, it descend and loose the bottling valve, bottling valve may automatically close. Bottle is discharged from the bottling machine along the clamp plate of starwheel drive V.

Capping part

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Hot Searches