- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±1%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

600 mm*800 mm*1550 mm, 600 mm*800 mm*1550 mm

-

Weight:

-

200 KG

-

Product name:

-

weighing filling machine

-

Rated pressure:

-

0.5-0.7Mpa

-

Function:

-

Filing

-

Usage:

-

Liquid paste quantitative canning

-

Filling speed:

-

20barrels/min

-

Filling range:

-

1-20KG

-

Total weight:

-

200kg

-

Can fill the range:

-

1-5000ml

Quick Details

-

Machinery Capacity:

-

1000BPH, 1200BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Filling Material:

-

Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≤±1%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

600 mm*800 mm*1550 mm, 600 mm*800 mm*1550 mm

-

Weight:

-

200 KG

-

Product name:

-

weighing filling machine

-

Rated pressure:

-

0.5-0.7Mpa

-

Function:

-

Filing

-

Usage:

-

Liquid paste quantitative canning

-

Filling speed:

-

20barrels/min

-

Filling range:

-

1-20KG

-

Total weight:

-

200kg

-

Can fill the range:

-

1-5000ml

Product Overview

|

Model

|

auto weighing filling machine

|

|

Voltage/powe

|

380V/According to the feed pump

|

|

housing

|

all contacted pipe adopts SS304

|

|

Pressure

|

0.5-0.7Mpa

|

|

Stainless steel pate thickness

|

1.5mm

|

|

fililing nozzle

|

filling range

|

capacity (b/min)

|

size (mm)

|

accuracy

|

|

2

|

1-5kg

|

4-6b

|

1400*1000*1800

|

1-5g

|

|

4

|

1-5kg

|

8-12

|

2400*1000*1800

|

1-5g

|

|

6

|

1-5kg

|

12-18

|

2800*1000*1800

|

1-5g

|

|

8

|

1-5kg

|

16-24

|

3200*1000*1800

|

1-5g

|

PRODUCT SPECIFICATIONS

18L automatic filling machine

Automatic capping machine

Automatic filling machine for big volumes

Automatic filling machine for big volumes

We provide all the equipment required for the production line equipment

Contact us for more information

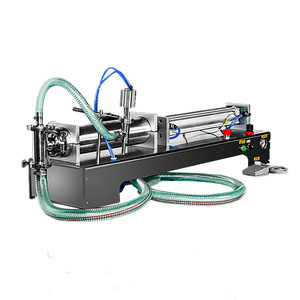

Automatic liquid filling machine

Product

Introduction:

Whole machine adopts human-computer interface, auto filling, easy to operate, high accuracy,fast speed.

304 stainless steel-- surface,

316 stainless steel-- material contact part

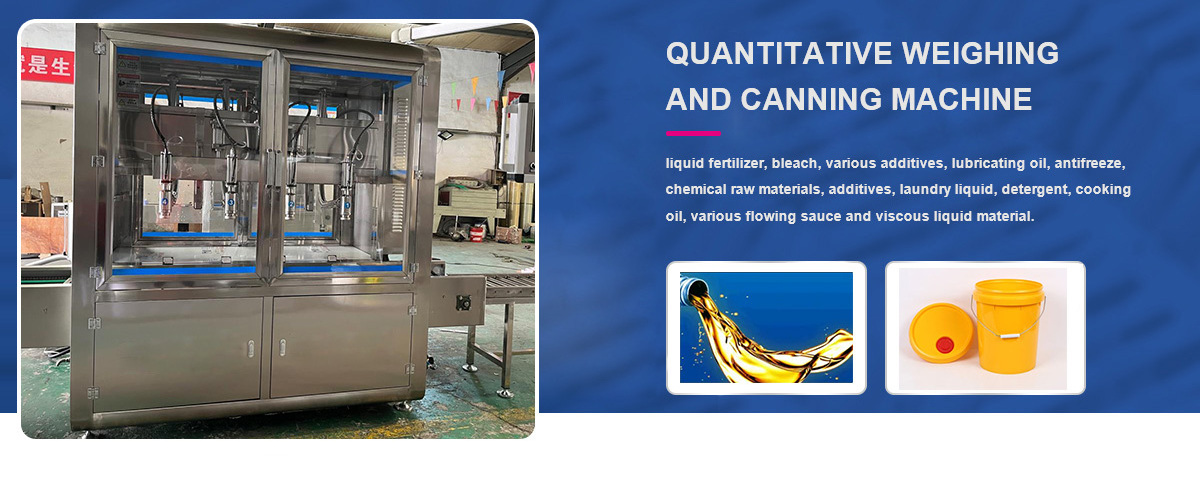

Application:

liquid fertilizer, bleach, various additives, lubricating oil, antifreeze, chemical raw materials, additives, laundry liquid, detergent, cooking oil, various flowing sauce and viscous liquid material.

Advantage:

The machine adopts the computer touch screen to input the filling weight directly, so that the operation is simpler and more user-friendly. High precision and fast speed. All interfaces are connected by quick connection, convenient cleaning, saving time and labor , and the machine has its own discharging system, making refueling faster and cleaner. Weighing type filling machine can be used in a single head, the appearance of the whole machine is made of stainless steel, the appearance of atmosphere, beautiful, clean and sanitary. Meet industry standards.

SIMILAR PRODUCTS

SALES AND SERVICE NETWORK

We provide professional customized production services

After the order is completed, it will be inspected by a third-party quality inspection agency

We offer multiple modes of transportation

Fast shipping

Install remote guidance and track after-sales service.

Q: How long will take for the delivery of product?

A: 7 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements,

usually about 30 days.

Q: What’s the insurance of after-sale service after purchase?

A: All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is

cost-effective during use, stable and reliable.

One year warranty service for all machine, please feel free to contact us if you have any questions.

Q: When the machine arrives at the work site, is it easy to install? How to solve the problem of quick installation and use?

A: All machine model with installation video, to show the installation process more intuitively, and we will provide remote video

technical support to solve your doubts and ensure that your installation is correct.

Q: During the use of the machine, how to get after-sale service?

A: We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging

with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we

will guide your workers directly.

Q: Will the accessories change frequently with machine ?

A: The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and

provide you with daily maintenance strategies.

A: 7 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements,

usually about 30 days.

Q: What’s the insurance of after-sale service after purchase?

A: All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is

cost-effective during use, stable and reliable.

One year warranty service for all machine, please feel free to contact us if you have any questions.

Q: When the machine arrives at the work site, is it easy to install? How to solve the problem of quick installation and use?

A: All machine model with installation video, to show the installation process more intuitively, and we will provide remote video

technical support to solve your doubts and ensure that your installation is correct.

Q: During the use of the machine, how to get after-sale service?

A: We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging

with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we

will guide your workers directly.

Q: Will the accessories change frequently with machine ?

A: The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and

provide you with daily maintenance strategies.

Hot Searches