- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MONA

-

Dimension(L*W*H):

-

896x745x935mm

-

Weight:

-

700 KG

-

Marketing Type:

-

Hot Product 2020

-

Product name:

-

Stone Crusher

-

Name:

-

Crusher Stone Machine

-

The Machines classification:

-

Crushing Line

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Time

-

Max feeding size:

-

250mm

-

After sale Service:

-

Life-long Service

-

Processed Materials:

-

River Stone

-

Advantage:

-

Long Lifework

Quick Details

-

Application:

-

Jaw Crusher

-

Capacity(t/h):

-

1-3

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MONA

-

Dimension(L*W*H):

-

896x745x935mm

-

Weight:

-

700 KG

-

Marketing Type:

-

Hot Product 2020

-

Product name:

-

Stone Crusher

-

Name:

-

Crusher Stone Machine

-

The Machines classification:

-

Crushing Line

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Time

-

Max feeding size:

-

250mm

-

After sale Service:

-

Life-long Service

-

Processed Materials:

-

River Stone

-

Advantage:

-

Long Lifework

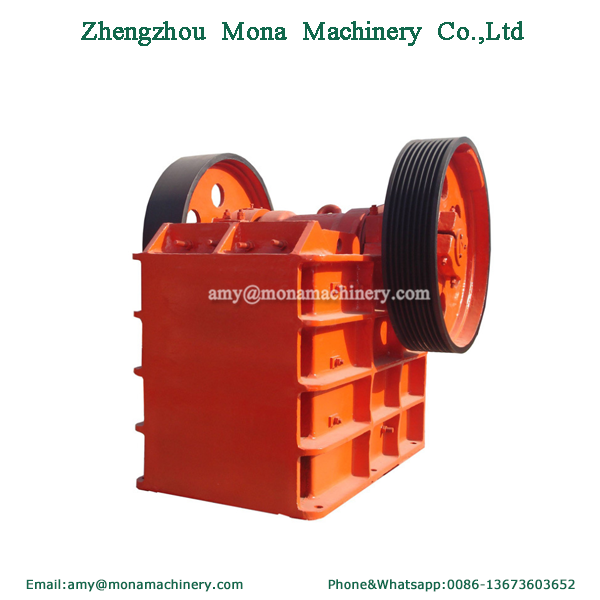

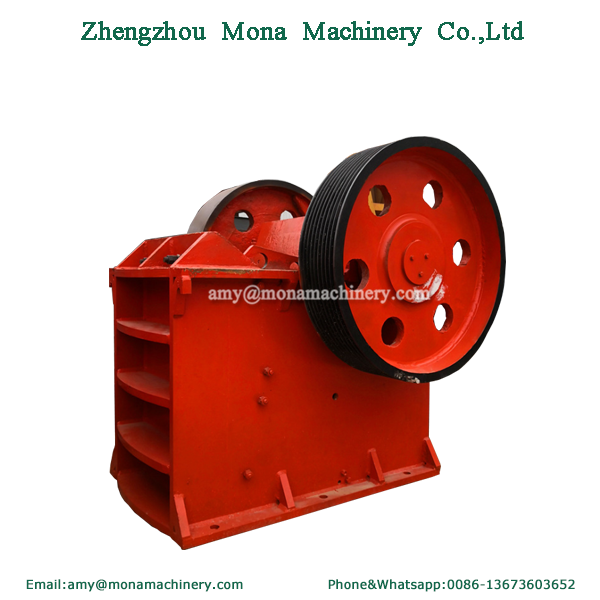

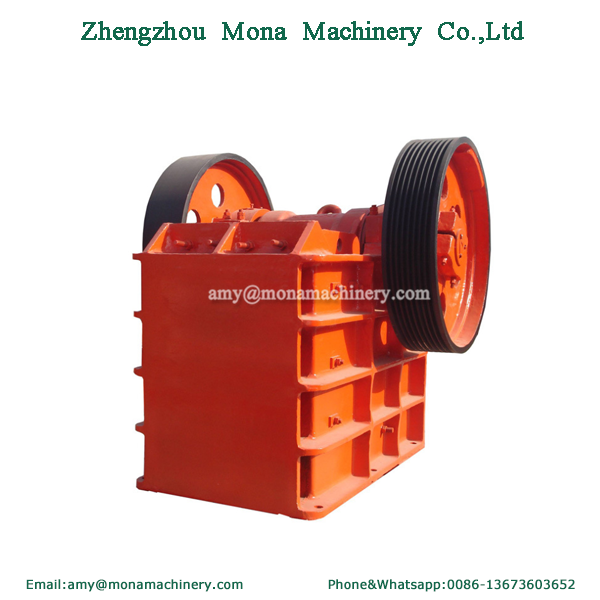

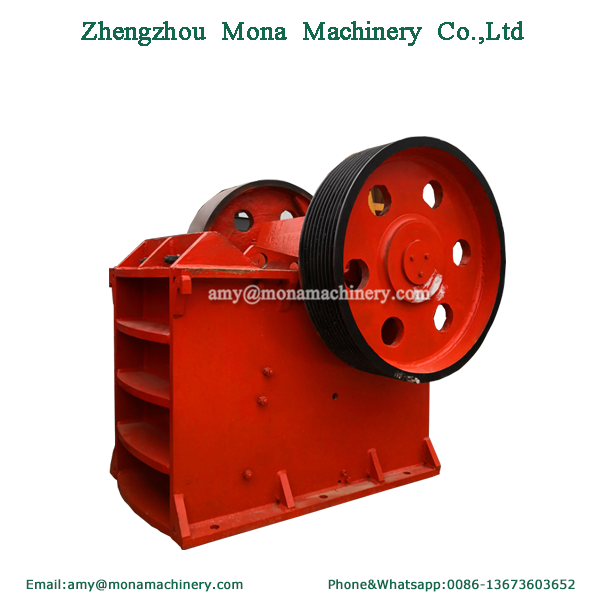

Crushing Jaw Breaking Pebble Jaw Crusher Construction Concrete Crusher for Stone Crusher Machine Factory Price Large Stone

Crushing Jaw Breaking Pebble Jaw Crusher Construction Concrete Crusher for Stone Crusher Machine Factory Price Large Stone

Intorduction of basalt crushing line jaw stone crusher primary quarry jaw crusher :

Jaw crusher are typically used as primary crushers, or the first step in the process of reducing rock. They typically crush using compression. The rock salt lump is dropped between two rigid pieces of metal, one of which then move inwards towards the rock, and the rock salt lump is crushed because it has a lower breaking point than the opposing metal piece.Jaw crusher movement is obtained by using a pivot point located at one end of the “swing jaw”, and an eccentric motion located at the opposite end.

Working principle of basalt crushing line jaw stone crusher primary quarry jaw crusher:

When the motor rotates the eccentric shaft through the belt, the vertical link moves upward and downward, when the vertical connecting rod to drive the two block, the toggle plate gradually stretched flat, forcing the movable jaw plate push toggle plate to the fixed jaw plate, By the fixed jaw plate and moving jaw space in the ore by the extrusion, splitting, folding and broken.

Application rock salt jaw crusher:

1. Jaw crusher is mainly used for the medium and fine crushing of hard ores and rocks in metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry and ceramic industry and other sectors.

2. Jaw crusher suitable for crushing all kinds of hard and soft ores with less than 300MPa compressive strength, such as pebble, calcite, granite, quartz, concrete, dolomite, blue stone, iron ore, limestone, iron ore, coal gaungue, construction waste, ferrosilicon, basalt, sandstone, ore, glass, cement clinker, rock salt lump and etc.

Advantages of rock salt jaw crusher:

1. The deep crushing cavity increases the feeding capacity and output capacity;

2. High ratio of crushing, homogeneous final product size;

3. Adjust the discharge opening through gasket, more convenient, it can meet different customers’ requirement;

4. Lubrication system is safe and reliable, easy to change the spare parts;

5. Simple structure, easy maintenance, consumption cost is lower;

6. Energy-saving, for one set saving about 15%-30%;

7. Little noise and dust;

Technical parameters of basalt crushing line jaw stone crusher primary quarry jaw crusher :

|

Model |

Feed opening size(mm) |

Max.Feeding size(mm |

Adjusting range of discharge opening(mm) |

Processing capacity (t/h) |

Mixing power(kw) |

Total weight(T) |

|

PE-150*250 |

150*250 |

125 |

10-40 |

1-3 |

5.5 |

0.8 |

|

PE-200*300 |

200*300 |

180 |

15-50 |

2-6 |

7.5 |

1.2 |

|

PE-200*350 |

200*350 |

180 |

18-70 |

3-10 |

11 |

1.5 |

|

PE-250*400 |

250*400 |

210 |

20-60 |

5-10 |

15 |

2.8 |

|

PE-400*600 |

400*600 |

340 |

40-100 |

16-60 |

30 |

7 |

|

PE-500*750 |

500*750 |

425 |

50-100 |

40-110 |

55 |

12 |

Raw material: