- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Application:

-

Chalk machine

-

Name:

-

Chalk Making Machine

-

Product name:

-

chalk moulding machine

-

Function:

-

chalk making machine price

-

Usage:

-

manual chalk making machine

-

Type:

-

Semi-automatic

-

Color:

-

Customer Requirement

-

Voltage:

-

380v/50HZ(as Customers' Request )

-

Weight:

-

45kg

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Shuliy

-

Weight (KG):

-

100

-

Marketing Type:

-

Hot Product 2021

-

Application:

-

Chalk machine

-

Name:

-

Chalk Making Machine

-

Product name:

-

chalk moulding machine

-

Function:

-

chalk making machine price

-

Usage:

-

manual chalk making machine

-

Type:

-

Semi-automatic

-

Color:

-

Customer Requirement

-

Voltage:

-

380v/50HZ(as Customers' Request )

-

Weight:

-

45kg

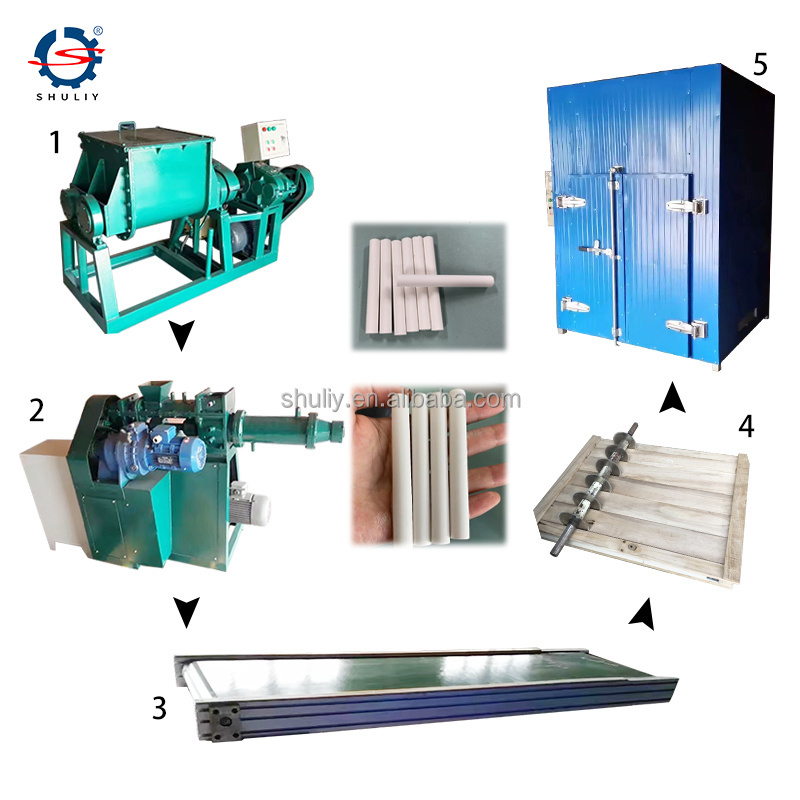

Brief Introduction of Chalk Making Machine

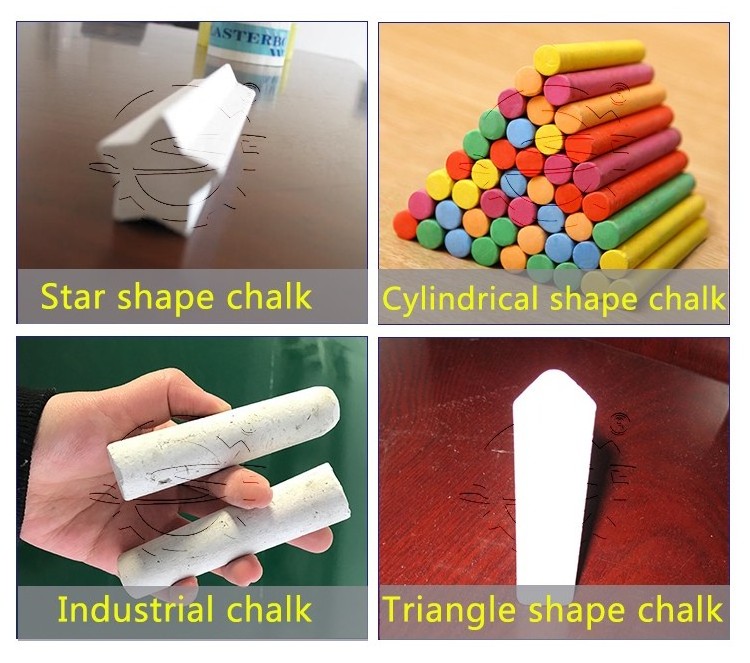

This machine is chalk making machine, also known as a chalk machine, chalk moulding machine. According to the customer's needs, we have different output chalk machines, mainly divided into manual chalk machine and electric chalk machine. The output of the electric chalk making machine is large, and there are 800 holes on each mold. It adopt electric beating, automatic water supply, which saving labor and time.The chalk moulding machine is easy to operate and only need one person.The chalk produced is beautiful in appearance, smooth in writing, not easy to break during use, and the user feeling good.Generally, the chalk is round shape, and we can also make chalks of various shapes such as square shape and star shape. We also support the customization, the customer can send us inquiry of chalk shape, after our engineer confirms, it can be produced. Customers can also add different paint to make colorful chalk in the processing according to market needs.

Feature of Chalk Making Machine

1.Big output,easy to operate.

2.It is good feeling when you use the chalk.

3.Our machine can do different chalk shape.

4.It is low electric consume when you use chalk making machine.

5.The produced chalk can keep long time.Won't change color.

Work Principle of Chalk Making Machine

The main raw material of chalk is calcium sulphate or calcium carbonate. After adding water, it needs to be stirred constantly to avoid solidification. After the mixed calcium sulphate is putted in the chalk machine mold, the mixed calcium sulphate begins to solidify in the mold, and the chalk has begun to be formed.After 10-15 minutes,the chalk in the mold can be taken out.Tap lightly when you take out the chalk.Put chalk in the sun and let it dry for two days, then you can start boxing and selling.

How to make beautiful chalk?

Step 1.Brush oil before using the chalk machine.New mold should brush more oil.

Step 2.Mix water and calcium sulfate of 8:10.

Step 3.Put the mixed calcium sulfate into the chalk mold.

Step 4.Scrape the excess mixed calcium sulfate out with a scraper.

Step 5.Take out the formed chalk after 15 minutes.

Step 6.After drying,you will get beautiful chalk.

Parameter of Chalk Making Machine

Tips

Raw Material

: calcium sulfate whiteness of more than 93%, fineness of more than 1,250 mesh. If it can't be reached,it is ok.Just affect the beauty of the chalk.Not affect the use effect.

Drying Machine

:If the local temperature is 20 degrees Celsius per day, we recommend that the chalk be dried naturally. If the customer's local temperature is too low, we offer drying machine,temperature range :30-120℃.Drying time around 12 hours.

We also offer the following services

Calcium sulfate

MOQ:10 T

Whiteness>93%, fineness >1250 mesh

Chalk Box

MOQ:100000 pcs

350g C1S material ,glossy laminated,4 color printing

Chalk Carton

MOQ :5000 pcs

49g corrugating paperboard paper.Thickness:3.5-5mm

Common chalk size

Analysis of Chalk Making Machine

Set:Output 6400 pcs/day,One box has 50 pcs chalk,One carton has 45 chalk box.One mould need 3 kg material.

Zhengzhou Shuliy Machinery Co.,Ltd ,established in 2010,is a professional manufacturer.We located in Zhengzhou city with convenient transportation. In recent years, our company has introduced a series of advanced environmental protection equipment including plastic pellet making machine,Egg tray making machine,Hydraulic Baler,Fiber Extracting machine,Fertilizer machine,Copper wire recycling machine,Shredding machine etc. In addition, we have obtained ISO,QUALITY,CE certificates.Our products are also exported to clients in such countries as Nigeria,Cameroon,Pakistan,Congo,Ghana,India,Philippines,Malaysia,Indonesia,Canada,Australia,Congo,Nigeria,Sudan,Saudi Arabia,,India,Russia,Mongolia,Kazakhstan and other countries.

We also welcome OEM and ODM orders. More request, you can talk to our customer service center about your purchasing requirements.

Q:Why Choose Us?

A:1). Several Year's Experience.We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery:We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.

Q:What should we do if we have problems during use?

A:We provide machine use video and operating manuals. At the same time, we also have after-sales service 24 hours online service.

Q:Can we customized motor voltage?

A:Yes.We will transform the voltage according to the customer's needs.