- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DATONG

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

3500 KG

-

Name:

-

PET bottle beer filling capping line

-

Product name:

-

soda water filling machine

-

Function:

-

Washing Filling Capping

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Material:

-

Stainless Steel

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-30000bph

-

Operation:

-

Automatic Operation

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

carbonated drink

-

Filling Accuracy:

-

99%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DATONG

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

3500 KG

-

Name:

-

PET bottle beer filling capping line

-

Product name:

-

soda water filling machine

-

Function:

-

Washing Filling Capping

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Material:

-

Stainless Steel

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-30000bph

-

Operation:

-

Automatic Operation

Products Description

Standard type of DCGF series hot filling machine is "3-in-1".aiming .

The bottles are sent to the bottle washing machine, the filling machine, the capping machine and finally through the conveyor chain. In this process, there are many protective alarm devices such as stuck bottles, lost bottles, lost lids and overloads.

Feature of carbonated drink filling machine.

Full filling avoids the bottle distorted after cooling and reduces dissolved oxygen at the maximum degree.product storage hopper and feed system adopts reasonable product feed design(constant flow,constant pressure,no foaming).product hopper with reasonable structure(exhaust,fully close,temperature can be detected).medium and high speed line adopts product distributor instead of large liquid carousel,which can be cleaned completely by pressure cleaning with CIP.sanitary filling valve system umbrella-flow type structure,high speed.perfect hot filling temperature control system.product recycle tank system with automatic product feed startup.perfect CIP system.

Technical Parameters

|

Model

|

DCGF14-12-5

|

DCGF16-16-6

|

DCGF18-18-6

|

DCGF24-24-8

|

DCGF32-32-10

|

DCGF40-40-12

|

DCGF50-50-15

|

DCGF60-60-15

|

|||||||

|

Production Capacity (b/h)

|

2000

|

3500

|

5000

|

7000

|

10000

|

15000

|

20000

|

24000

|

|||||||

|

Suitable bottle shape

|

Circular or square

|

|

|

|

|

|

|

|

|||||||

|

Bottle diameter (mm)

|

Φ50-Φ95

|

|

|

|

|

|

|

|

|||||||

|

Bottle height (mm)

|

150-310

|

|

|

|

|

|

|

|

|||||||

|

washing medium

|

aseptic water

|

|

|

|

|

|

|

|

|||||||

|

Total power (kw)

|

3

|

3.5

|

4

|

5.5

|

7.5

|

11

|

15

|

20

|

|||||||

|

weight(kg)

|

2200

|

2800

|

3000

|

4500

|

6000

|

9000

|

15000

|

18000

|

|||||||

|

Overall dimensions (mm)

|

2050*1550*2200

|

2400*1750*2200

|

2550*1850*2200

|

3000*2150*2200

|

4200*2700*2400

|

4700*3200*2400

|

6500*3350*2400

|

7200*3650*2600

|

|||||||

Details Images

Washing Part

Specially designed stainless steel bottle gripper does not contact the thread parts of the bottle neck,avoiding the second contamination. With stainless steel washing tube.

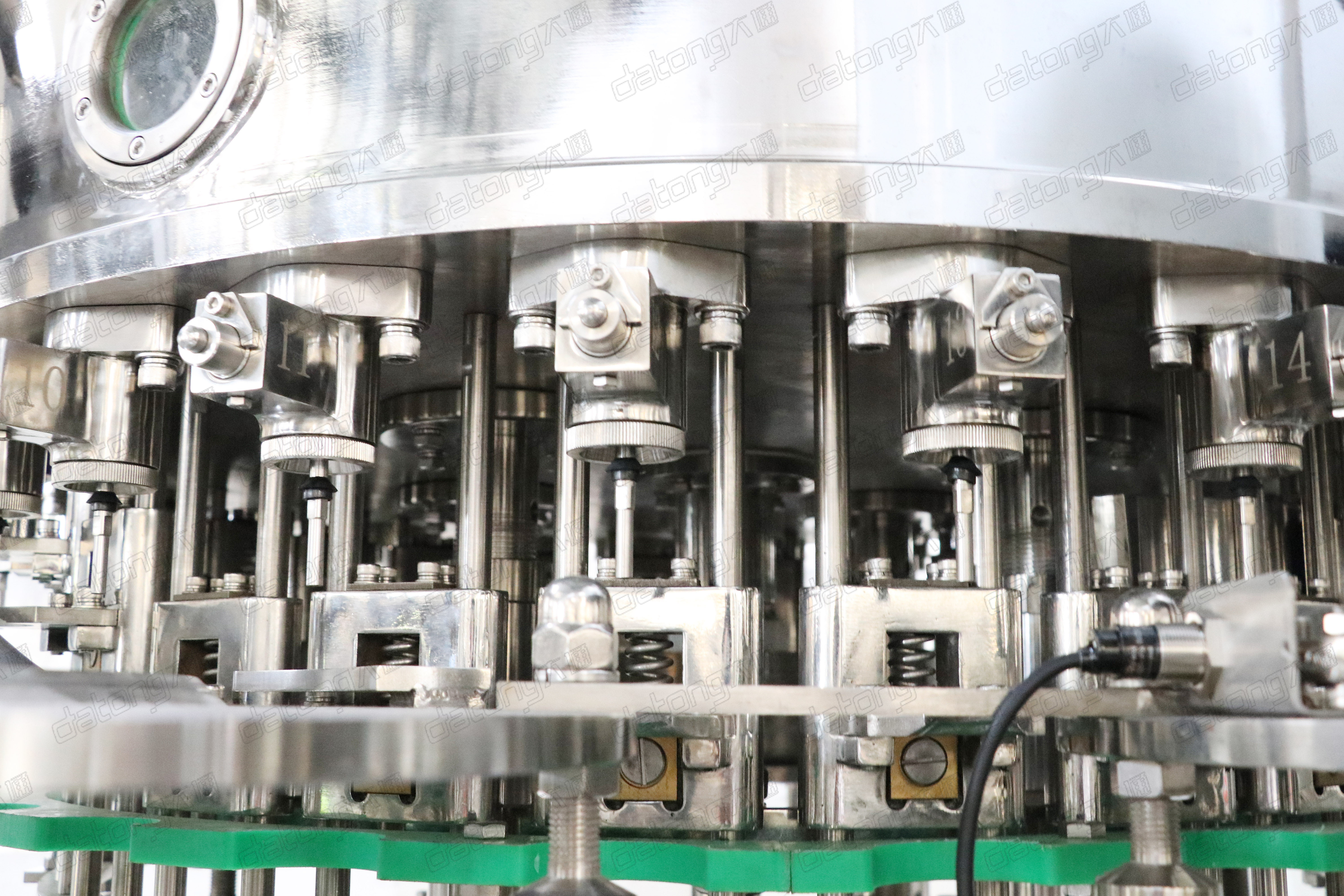

Filling Part

Filling valve have itself reflux device,Vacuum device increase the liquid level.High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

Capping Part

The capping system applies advanced French technology,when clamp the cap will screw immediately and magnetic torque type capping head capping, itself has scale.Easier adjust and count.

About DaTong

Before Sales

1.Answer your any question on us within 24 hours.

2.Supply all information you required.

3.Machines video for reference

4.Welcome to visit factory

On Sales

1.Update production progress each week

2.Sending machines pictures on production

3.Machines testing running over 8 hours, and sending testing videos

After Sales

1.engineer arranged to install machines

2.Spare Parts provided

3.After sales hotline: 0086-512-5866208.

1.Answer your any question on us within 24 hours.

2.Supply all information you required.

3.Machines video for reference

4.Welcome to visit factory

On Sales

1.Update production progress each week

2.Sending machines pictures on production

3.Machines testing running over 8 hours, and sending testing videos

After Sales

1.engineer arranged to install machines

2.Spare Parts provided

3.After sales hotline: 0086-512-5866208.

Certifications

Exhibition

DaTong With Customer & Service

Product packaging

The machine are packed in wooden case to protect the machine from impact and friction,the size is accord -ing to the machine.We will choose good public praise shipping company to transport your machines that makes the transportation time be short and make sure that your machine are safe.

FAQ

Q1:Are you a factory or trading company?

A1:We are a factory, professional water treatment equipment manufacturer and small bottle water production line with about 20 years experience. Factory covers an area of 6000 square. There have been more than 40 countries use our products.

Q2:What is the features of your company?

A: We provide turnkey project for customers, including pre-sale and after-sale service; complete production line equipment supply;bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas;installation and commissioning; operator training; etc

Q3:How long is the warranty of your equipment?

A3: years warranty after receipt check upon delivery.And we will comprehensively provide you all kinds of technical support.services in after-sale !

Q4: Why is your prices higher than others?

A4: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q5: What is your delivery time?

A5: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

A1:We are a factory, professional water treatment equipment manufacturer and small bottle water production line with about 20 years experience. Factory covers an area of 6000 square. There have been more than 40 countries use our products.

Q2:What is the features of your company?

A: We provide turnkey project for customers, including pre-sale and after-sale service; complete production line equipment supply;bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas;installation and commissioning; operator training; etc

Q3:How long is the warranty of your equipment?

A3: years warranty after receipt check upon delivery.And we will comprehensively provide you all kinds of technical support.services in after-sale !

Q4: Why is your prices higher than others?

A4: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q5: What is your delivery time?

A5: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q6: What is your payment term?

A6: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

A6: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Hot Searches