We utilize a number of molding process technologies such as: transfer compression molding, spin casting, open casting and vacuum casting to low pressure injection molding. We manufacture products ranging from wheels to wipers in sizes from 1 gram to 2,000lbs. We use state-of-the-art casting machines with outputs ranging from 200 grams per minute to 125 pounds per minute. We carry awide array of urethane material systems and additives which allow us to not only meet performance requirements of our customers,but accomodate pricing as well.For more information on the typical processing methods that we use in our manufacturing process, or to view more of the cast

products we manufacture, please visit the pages below.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

6985

-

Product name:

-

Excellent impact resistance plastic pu tube

-

Material:

-

PU

-

Color:

-

Customized Colors

-

Certification:

-

ISO9001

-

Size:

-

Customer Size Accepted

-

Service:

-

ODM OEM

-

Drawing Format:

-

CAD

-

Application:

-

Industrial Plastic Parts

-

Surface treatment:

-

Customers' Detailed Request

-

Package:

-

Wooden Box

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GZ engineering plastics

-

Model Number:

-

6985

-

Product name:

-

Excellent impact resistance plastic pu tube

-

Material:

-

PU

-

Color:

-

Customized Colors

-

Certification:

-

ISO9001

-

Size:

-

Customer Size Accepted

-

Service:

-

ODM OEM

-

Drawing Format:

-

CAD

-

Application:

-

Industrial Plastic Parts

-

Surface treatment:

-

Customers' Detailed Request

-

Package:

-

Wooden Box

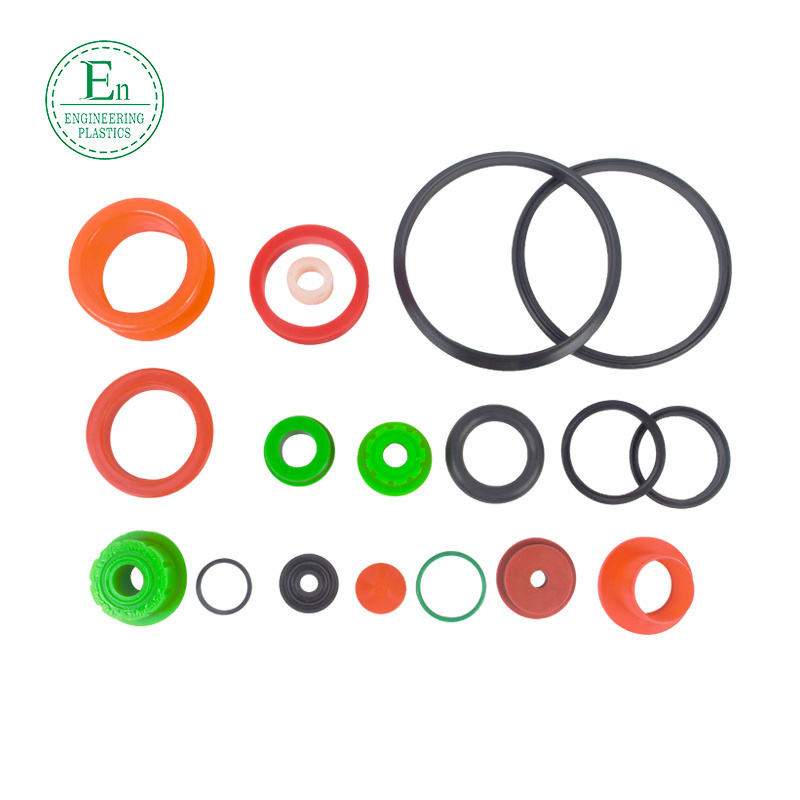

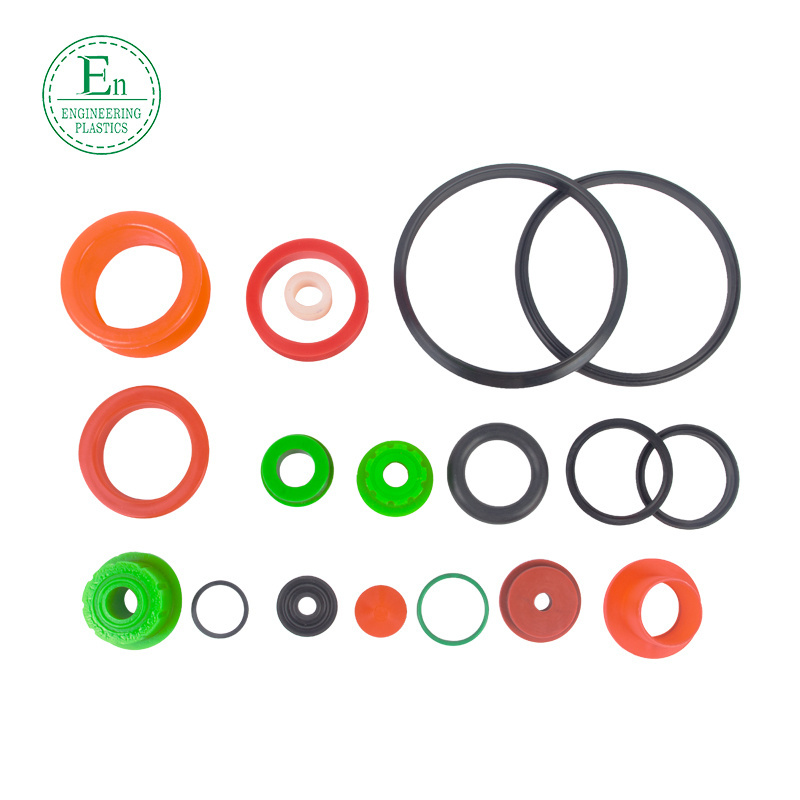

High pressure resistance cast urethane oring PU Polyurethane O Ring Seals Ring URETHANE O-RINGS

Product Display

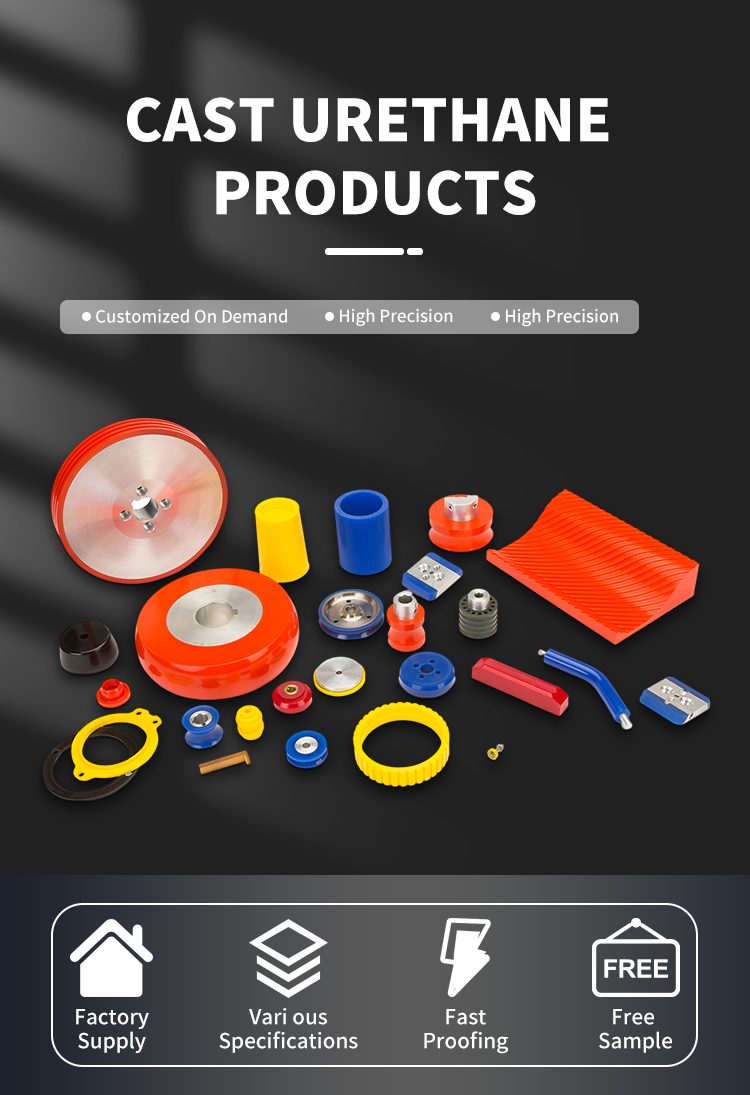

CAST URETHANE PRODUCTS

CUSTOMIZED SOLUTIONS

Precision Urethane has manufactured countless urethane parts and products used in many industries worldwide. We provide cast polyurethane manufacturing solutions for high and low volume production. Manufactured using high-performance resins, curatives and

additives, our cast polyurethane products can be manufactured in almost any hardness or shape. This is possible through a number of manufacturing processes which employ state-of-the-art technology at each processing step. With experience in highly customized

products, we welcome complicated projects and difficult applications.

additives, our cast polyurethane products can be manufactured in almost any hardness or shape. This is possible through a number of manufacturing processes which employ state-of-the-art technology at each processing step. With experience in highly customized

products, we welcome complicated projects and difficult applications.

|

Advantages of Polyurethane When Compared to Conventional Materials

|

|

|

||

|

vs. Rubber

|

vs. Metal

|

vs. Plastic

|

||

|

High abrasion resistance

|

Lightweight

|

High impact resistance

|

||

|

High cut & tear resistance

|

Noise reduction

|

Elastic memory

|

||

|

Superior load bearing

|

Abrasion resistance

|

Abrasion resistance

|

||

|

Thick section molding

|

Less expensive fabrication

|

Noise reduction

|

||

|

Colorability

|

Corrosion resistance

|

Variable coefficient of friction

|

||

|

Oil resistance

|

Resilience

|

Resilience

|

||

|

Ozone resistance

|

Impact resistance

|

Thick section molding

|

||

|

Radiation resistance

|

Flexibility

|

Lower cost tooling

|

||

|

Broader hardness range

|

Easily moldable

|

Low temperature resistance

|

||

|

Castable nature

|

Non-conductive

|

Cold flow resistance

|

||

|

Low pressure tooling

|

Non-sparking

|

Radiation resistance

|

||

POLYURETHANE ROLLERS & WHEELS

Polyurethane rollers are one of Precision Urethane's most popular product lines. We have over 15+ years of experience as a urethane roller manufacturer and have accumulated a large selection of tooling which allows us to cast most customer orders with little or no tooling cost. With a full service CNC machining division to support new core machining or recovering / repair of existing rollers, we are able to provide a turnkey solution while controlling lead times and overall product quality.

URETHANE & POLYURETHANE BUSHINGS

At Precision Urethane, our focus is our customers and we strive to find ways to save them money when they choose a polyurethane bushing. Our cast polyurethane bushings and bearings are used in frictional or corrosive environments and can eliminate down time and reduce replacement costs. We cast low and high volume production runs with economical tooling costs and typical lead times are 2-4 weeks from start to finish including tooling. We offer large polyurethane bushings in excess of 2000 lbs with custom formulated options.

Custom cast urethane bushings and bearings are often used in automotive parts or industrial equipment because of their benefits over rubber products and the way they can be molded into unique designs to suit your needs. Since rubber is biodegradable, it is

more susceptible to deterioration over time caused by environmental factors, whereas polyurethane is stronger and can last for the lifetime of your application.

Custom cast urethane bushings and bearings are often used in automotive parts or industrial equipment because of their benefits over rubber products and the way they can be molded into unique designs to suit your needs. Since rubber is biodegradable, it is

more susceptible to deterioration over time caused by environmental factors, whereas polyurethane is stronger and can last for the lifetime of your application.

POLYURETHANE RINGS

We can isolate specific physical properties needed for any application that may be subject to dynamic loads which include hydraulics, pneumatics and in a wide range of other critical areas. Our polyurethane rings are manufactured from high performance

prepolymers and will meet or exceed the highest standards, which in turn reduces down time and replacement costs. We maintain complete sets of tooling for many standard sizes and can grind our rings to very tight tolerances.

Advantages of Polyurethane Rings

* Available in multiple hardness ranges to meet performance and cost requirements

* Excellent tear and abrasion resistance, which prevents fast aging

* Resistant to a wide range of chemical agents such as: ozone, hydraulic oil and gasoline, pure aliphatic hydrocarbons (propane,butane, fuel) and silicone oils and greases

prepolymers and will meet or exceed the highest standards, which in turn reduces down time and replacement costs. We maintain complete sets of tooling for many standard sizes and can grind our rings to very tight tolerances.

Advantages of Polyurethane Rings

* Available in multiple hardness ranges to meet performance and cost requirements

* Excellent tear and abrasion resistance, which prevents fast aging

* Resistant to a wide range of chemical agents such as: ozone, hydraulic oil and gasoline, pure aliphatic hydrocarbons (propane,butane, fuel) and silicone oils and greases

URETHANE SHEAVES & PULLEYS

The cast urethane sheave and pulley products we manufacture range from 1” to over 48” diameter polyurethane sheaves. With our large machining capacity, we have the ability to machine cores and the profiles in house or mold them for volume production. We offer a variety of formulations that are engineered to perform in applications ranging from subsea to subzero.

* In-House Machining Services

* Cost-Effective Prototyping

* Application Specific Formulations

* In-House Machining Services

* Cost-Effective Prototyping

* Application Specific Formulations

POLYURETHANE GEARS & SPROCKETS

Our large cast polyurethane gears offer solutions to problems other materials cannot. They are impact, chemical and abrasion resistant, yielding properties that cannot be achieved using rubber or steel. The teeth flex allowing for slight misalignment yet

retain the rigidity to perform. If requested, We can design custom polyurethane gears using a specific durometer so they will sheer, saving more expensive parts of equipment.

retain the rigidity to perform. If requested, We can design custom polyurethane gears using a specific durometer so they will sheer, saving more expensive parts of equipment.

Product Paramenter

|

Company Name

|

Guangdong Engineering plastics Industries(Group)Co,Ltd

|

|

|

|

|||

|

Brand

|

Guangdong Engineering plastics

|

|

|

|

|||

|

Main Product

|

Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc

|

|

|

|

|||

|

Injection Machine

(Double Color)

|

88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T

|

|

|

|

|||

|

Application

|

Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc

|

|

|

|

|||

|

Mould Base

|

LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc.

|

|

|

|

|||

|

Mould Material

|

718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc

|

|

|

|

|||

|

Moud Precision

|

+/-0.01mm

|

|

|

|

|||

|

Mould Life

|

100k-1000K shots

|

|

|

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity

|

|

|

|

|||

|

Runner System

|

Hot runner and cold runner

|

|

|

|

|||

|

Manufacturing Equipments

|

Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc

|

|

|

|

|||

|

Plastic Raw Material

|

Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

|

|

|

|

|||

|

Color

|

white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc

|

|

|

|

|||

|

Surface Treatment Tech

|

Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting…

|

|

|

|

|||

|

Product Drawings

|

2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures

|

|

|

|

|||

|

Lead time

|

15-30 working days for injection moulds,plastic products according to quantity

|

|

|

|

|||

|

Quanlity System

|

ISO 9001, RoHS Srandard, etc

|

|

|

|

|||

|

Our Spirit

|

"Engineering Plastics" can be used instead of "Steel"!

Science and technology will change the future!

Guangdong Engineering Plastics Industries Company!

|

|

|

|

|||

|

Other

|

24 hours instant and comfortable customer service!

|

|

|

|

|||

|

|

Shipping status notification during delivery!

|

|

|

|

|||

|

|

Regular notification of new styles & hot selling styles!

|

|

|

|

|||

Injection Process

Our Factory

(Our factory has 100 sets of precision processing equipment, welcome to visit our factory!)

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu

RoHS standard.

Professional Team

Guangdong Engineering Plastics Industries Co., Ltd! We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for morethan 15 years! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support

personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines.

We can customize all kinds of Engineering plastics products according to our

customers’drawings or samples.

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Our Exhibition & CCTV Interview

Application

Cooperation

FAQ

Q1. Can only samples be produced?

A1. Yes

Q2. What is the accuracy of the products processed by the drawings?

A2. Different

equipment has different accuracy, generally between 0.05-0.1

equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,

electroplating, etc.

electroplating, etc.

Hot Searches