- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Voltage:

-

380V 50Hz 3 Phrase

-

Weight:

-

3000 kg

-

Feeding width:

-

According to drawing

-

Marketing Type:

-

New Product

-

Product name:

-

Drip edge roll forming machine

-

Raw material:

-

Galvanized Steel Sheet

-

Roller material:

-

45#steel Chrome Plated

-

Material thickness:

-

0.3-0.8mm Galvanized Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(detla) System

-

Cutting type:

-

Hydraulic Cutting

-

Material of rollers:

-

45#steel Hard Chrome Coated

Quick Details

-

Type:

-

Roll forming machine

-

Tile Type:

-

galvanized sheet

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Voltage:

-

380V 50Hz 3 Phrase

-

Weight:

-

3000 kg

-

Feeding width:

-

According to drawing

-

Marketing Type:

-

New Product

-

Product name:

-

Drip edge roll forming machine

-

Raw material:

-

Galvanized Steel Sheet

-

Roller material:

-

45#steel Chrome Plated

-

Material thickness:

-

0.3-0.8mm Galvanized Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(detla) System

-

Cutting type:

-

Hydraulic Cutting

-

Material of rollers:

-

45#steel Hard Chrome Coated

Product Description

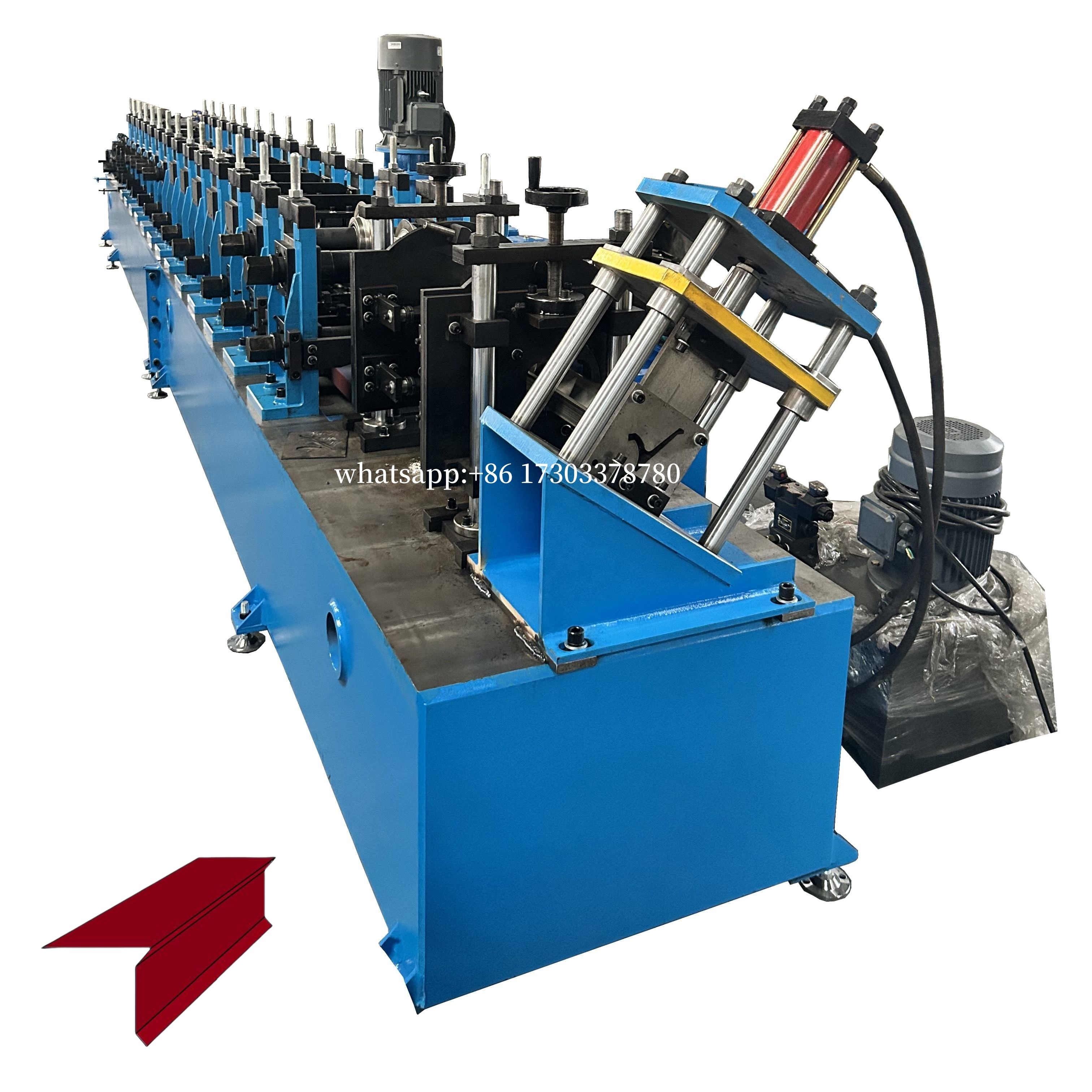

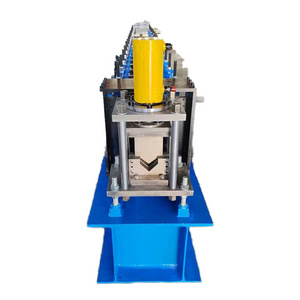

Metal Drip Edge Flashing Roll Forming Machine

A Drip Edge Roll Forming Machine is a specialized piece of equipment used in the construction and roofing industry to produce drip edges, which are essential components for roof installations.

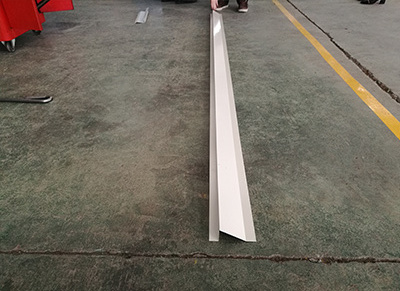

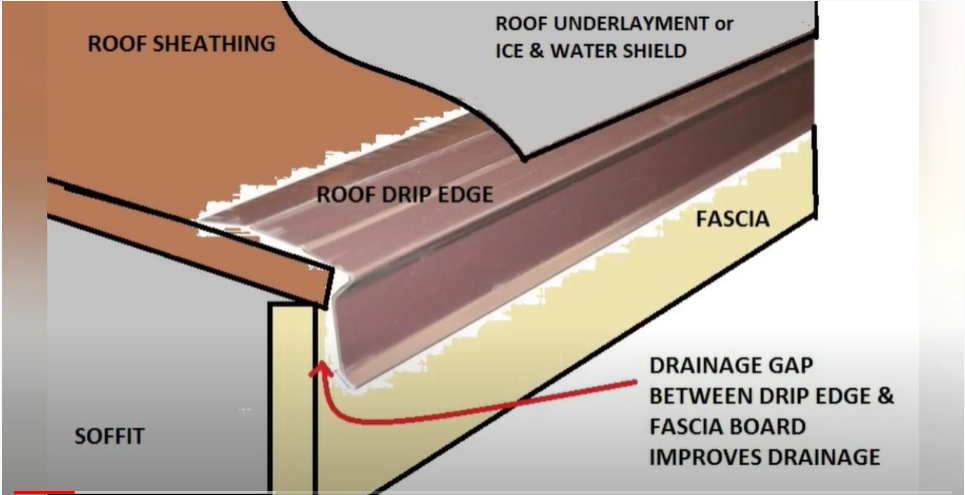

Drip edge is metal flashing installed at the edges of the roof to keep water away from your fascia and from getting underneath your roofing components.

The components of the include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receiving table.

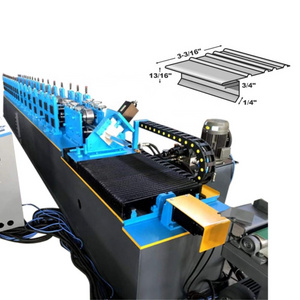

Specification

|

Material Thickness

|

0.3-0.8mm

|

|

Rolling Speed

|

8-12m/min

|

|

Roller Material

|

Gcr15 coated with chrome

|

|

Power

|

4kw

|

|

Material Of Cutting

|

CR12mov with quench treatment

|

|

Control System

|

PLC (Delta) as list in the note

|

|

Way Of Drive

|

By chain

|

Application

Shingle or slate roof flashing with an overhanging component and outward projecting lower edge intended to protect the eave by diverting water away from the building and into the gutters. Hemmed edges to provide strength.

Drip edges are metal strips that are installed along the edges of a roof to protect it from water damage and help direct rainwater away from the structure. These machines automate the process of manufacturing drip edges by continuously forming and shaping metal sheets into the desired profiles.

Drawing of drip edge roll forming machine

Related products

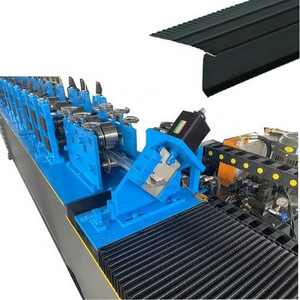

Corrugated roofing sheet roll forming machine

The tile pressing machine is economical and affordable, which can combine different models of equipment into one, saving space and the cost of the tile pressing machine is much lower than that of two single-layer machines.

Trapezoidal ibr roofing tile iron sheet roll forming machine

The tile pressing machine is mainly suitable for civil buildings of large and medium-sized enterprises, such as factories, sports venues, locomotive hangars, aircraft hangars, exhibition halls, cinemas, etc.

Glazed roofing sheet roll forming machine

This type of machine is commonly used in the construction industry to produce roofing sheets that are durable, weather-resistant, and aesthetically pleasing. Glazed roofing sheets are often used in commercial and residential buildings to provide a stylish and functional roofing solution.

Our Advantages

Hot Searches