- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2600

-

Application:

-

Polishing

-

Product name:

-

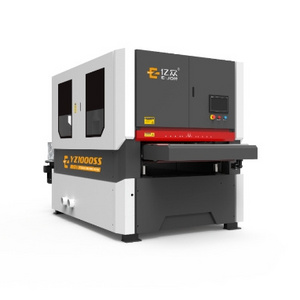

Automatic Metal Polishing Machine

-

After-sales Service Provided:

-

Video Technical Support

-

Usage:

-

Workpieces Surface Deburring Polishing

-

Function:

-

Metal Surface Grinding Polishing

-

Keyword:

-

Metal Surface Polishing Machine

-

Machine Type:

-

Automatic Grinding Polishing

-

Advantage:

-

Polishing Brighter

-

Type:

-

Fully Automatic

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

XINREBON/OEM

-

Power (kW):

-

36

-

Weight (KG):

-

2600

-

Application:

-

Polishing

-

Product name:

-

Automatic Metal Polishing Machine

-

After-sales Service Provided:

-

Video Technical Support

-

Usage:

-

Workpieces Surface Deburring Polishing

-

Function:

-

Metal Surface Grinding Polishing

-

Keyword:

-

Metal Surface Polishing Machine

-

Machine Type:

-

Automatic Grinding Polishing

-

Advantage:

-

Polishing Brighter

-

Type:

-

Fully Automatic

-

Certification:

-

CE ISO

You can send samples to test whether the performance of the machine meets the requirements

We can help you test for free

And record the whole video and send it to you

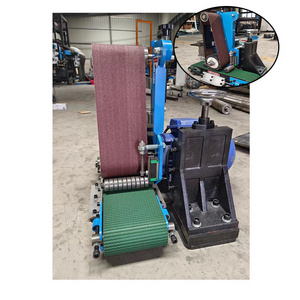

Equipment usage:

They support laser cutting machines, CNC stamping, various CNC processing or other machining deburring front production lines. The equipment is processed in a straight line, and multiple sets of grinding wheels rotate, revolve, and alternate, which can genuinely and uniformly remove the burrs on the surface, contour edge, and hole edge of the part at one time and even chamfer.

|

model

|

A variety of models are available at favorable prices

|

|

Equipment processing width

|

100-1300mm

|

|

Optional feeding method

|

(1) Conveyor belt feeding (suitable for common workpieces. Workpiece length ≥ 150mm) Rubber roller test feeding (suitable for

common workpieces. Workpiece length ≥ 300mm) (2) Powerful permanent magnetic adsorption conveying and feeding (suitable for carbon steel workpieces. Workpiece size ≥ 10mmx 10mm) (3) Vacuum negative pressure adsorption conveying material (suitable for stainless steel plates, copper plates, aluminum plates, etc. not to be magnetically adsorbed. Workpiece size ≥ 50mmx 50mm) (4) Abrasive belt line speed: 18m/s (optional frequency conversion speed regulation) (5) Brush wheel linear speed 8-20m/s (optional frequency conversion speed regulation) (6) Conveying and feeding speed: 1-10m/min (frequency conversion speed regulation) (7) Adjust the processing parameters on the CNC PLC touch screen of the whole machine It is equipped with a wet vacuum cleaner or an industrial pulse vacuum cleaner to handle grinding dust to achieve environmentally friendly production. |

Equipment performance and characteristics:

9) The equipment is equipped with a dust collector interface to suck away the dust, metal chips and dust generated during the working process of the equipment. You can choose a separate dust removal equipment or link the existing equipment in the factory.

Qingdao XINREBON CNC Technology CO., LTD

XINREBON CNC TECHNOLOGY CO., LTD, we are a professional manufacturing company. The factory is located in Shandong province, 20 km from Qingdao port and only 10 km from the high speed railway station. Based on efficient transportation, our machines can reach consumers directly and easily. We always walk on the road of technological innovation and our products are constantly upgraded. Currently, our machines serve consumers in more than 20 provinces in China and more than 30 countries abroad, enjoying high reputation and acclaim. Combined with years of experience, we have won the trust and praise of our customers. Now we produce all kinds of woodworking machines, including edge banding machines, cold/hot presses, planers, sanding machines, polishing machines, CNC routers, CNC panel cutting saws, horizontal band saws, multi-row drilling machines, precision push table sawing machines, various solid wood processing machines, etc. Our philosophy: professional, efficient and loyal, our mission: to create core value for our customers, our employees and our company..

Q1: Can you provide OEM or ODM services?

A: Of course, we have our own design department, and we can provide OEM or ODM services for you.

Q2: What is your minimum order quantity?

A: Hello, the minimum order quantity we support is one.

Q3: How long is the warranty period of your machine and what kind of warranty service can I get?

A: Our machines are provided with a one-year after-sales warranty and lifelong service. If there is any problem with the machine, please contact us. We guarantee to solve the problem for you within 24-48 hours, and if the machine parts are damaged for non-human reasons during the warranty period, we can send you free parts, except for consumables.

Q4: If I pay for the goods, when will you deliver the goods?

A: Hello, the normal machines are in stock. We will deliver the goods to the shipping company within 5-7 days to achieve fast shipment, but the shipping time depends on the shipping company.

A: Of course, we have our own design department, and we can provide OEM or ODM services for you.

Q2: What is your minimum order quantity?

A: Hello, the minimum order quantity we support is one.

Q3: How long is the warranty period of your machine and what kind of warranty service can I get?

A: Our machines are provided with a one-year after-sales warranty and lifelong service. If there is any problem with the machine, please contact us. We guarantee to solve the problem for you within 24-48 hours, and if the machine parts are damaged for non-human reasons during the warranty period, we can send you free parts, except for consumables.

Q4: If I pay for the goods, when will you deliver the goods?

A: Hello, the normal machines are in stock. We will deliver the goods to the shipping company within 5-7 days to achieve fast shipment, but the shipping time depends on the shipping company.

Hot Searches