- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

twilight

-

Use:

-

FTTH

-

Warranty Time:

-

1

-

Products::

-

Fiber optic Curing Oven

-

jig Type::

-

LC SC FC ST MU mtrj

-

Power:

-

AC220V ,200W

-

Transport Package::

-

Wooden Packaging

-

Max Heating temperature:

-

200℃

-

Normal Curing Temperature:

-

80~120℃

-

Normal curing period:

-

30~45min

Quick Details

-

Type:

-

Fiber Optic Production Machine

-

Model Number:

-

TW-CO

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

twilight

-

Use:

-

FTTH

-

Warranty Time:

-

1

-

Products::

-

Fiber optic Curing Oven

-

jig Type::

-

LC SC FC ST MU mtrj

-

Power:

-

AC220V ,200W

-

Transport Package::

-

Wooden Packaging

-

Max Heating temperature:

-

200℃

-

Normal Curing Temperature:

-

80~120℃

-

Normal curing period:

-

30~45min

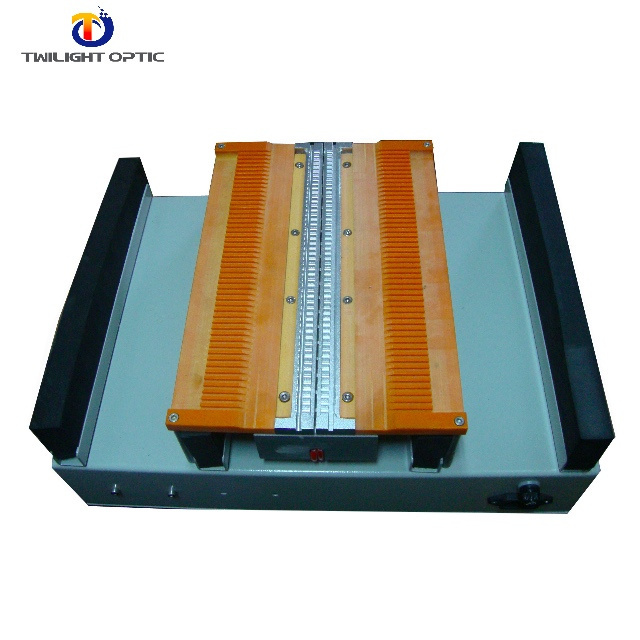

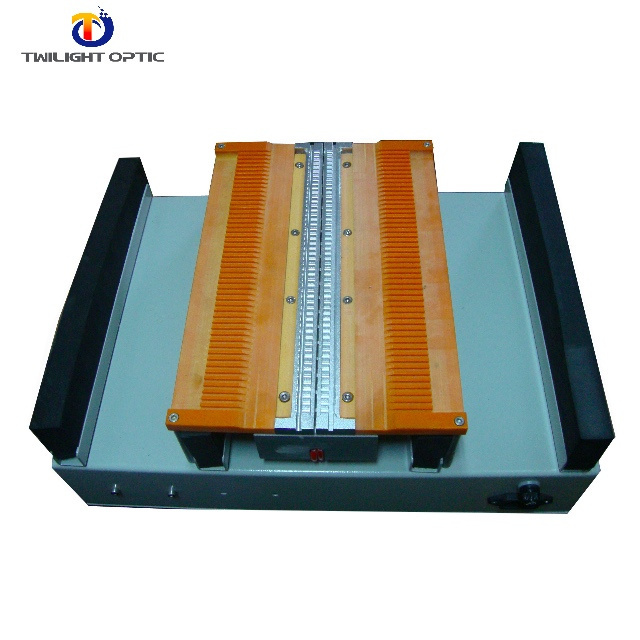

Fiber Optic Connector Hot Curing Ovens

The fiber curing oven for engineering has excellent performance comparing to the command of fiber curing process.

Product Detail

| Products: | Fiber optic Curing Oven |

| jig Type: | LC SC FC ST MU mtrj |

| Power | AC220V ,200W |

| Transport Package: | Wooden Packaging |

| Max Heating temperature | 200℃ |

| Normal Curing Temperature | 80~120℃ |

| Normal curing period | 30~45min |

| Product Keywords | Fiber Optic Connector Hot Curing Ovens |

Features:

Heating for almost kind of fiber optic ,such as FC,SC,LC,MU,MT,ST etc.

Two independence control system , 48 ferrules can be heated at the same time at most.

High productivity.

Heat even to exhaust the least.

Precise control system , adjustable temperature 60~150℃ , fluctuation ±1℃ only.

Control the heating time by designation.

Easy to use and dependable.

Technical parameters:

Power : 220V, 600W

The highest heating temperature: 200 degrees

Curing temperature: 80 ~ 120 degrees

Curing time: 30 to 45 minutes.

Capacity: 1 ~ 48 connectors

Optical fiber curing process procedures:

1.Power

2.Set temperature, curing time, equipment automatic preheating.

3.Wear the fiber core to the board, holding to solidify as:

4.When the temperature of equipment reaches the preset temperature , after the full optical fiber connectors install to cure oven , position the picture below:

5.As the timer switch, equipment and automatic core timing starts.

6.When curing ,in another side of curing board can install pacth cord connetcor ,save time, improve efficiency.

7.Equipment to set curing time, when it is over, it will automatic alarm equipment.

8.Press the switch, alarm clock, automatic stop under the curing furnace has been good, and another installed on board,

9.Press the timer switch again , for the next