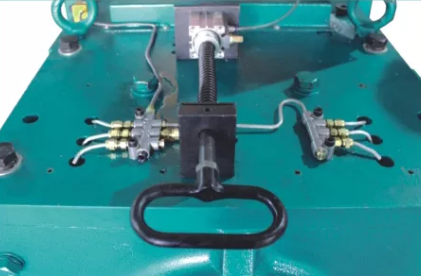

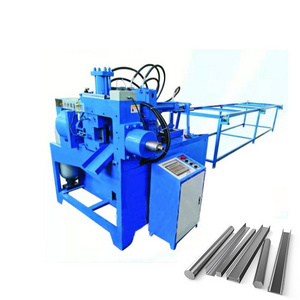

The automatic lubrication system consists of CNC lubricating oil pump and oil separator.It can automatically and accurately refuel

to each refueling point, which is convenient and practical, and eliminates the hidden danger of wear caused by lack of oil.