- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

cgy

-

Voltage:

-

380

-

Year:

-

2023

-

Power (kW):

-

37

-

Weight (KG):

-

7600 KG

-

Name:

-

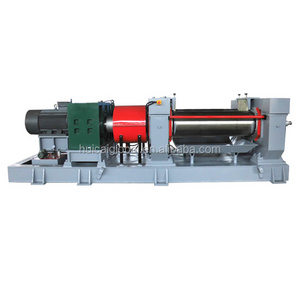

open roller mill mixing machine

-

After-sales Service Provided1:

-

Engineers available to service machinery overseas

-

The material of the roll:

-

Chilled cast Iron

-

Two kind of bush:

-

Nylonbush,bearing bush

-

Weight:

-

1t-22t

-

Power:

-

1.5KW - 75 KW

-

After-sales Service Provided2:

-

Online support

-

After Warranty Service:

-

Online support

-

Certification:

-

CE ISO

-

COLOR:

-

Customers' Demand

Quick Details

-

Diameter of Roll(mm):

-

400 mm

-

Length of Roll(mm):

-

1000 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

cgy

-

Voltage:

-

380

-

Year:

-

2023

-

Power (kW):

-

37

-

Weight (KG):

-

7600 KG

-

Name:

-

open roller mill mixing machine

-

After-sales Service Provided1:

-

Engineers available to service machinery overseas

-

The material of the roll:

-

Chilled cast Iron

-

Two kind of bush:

-

Nylonbush,bearing bush

-

Weight:

-

1t-22t

-

Power:

-

1.5KW - 75 KW

-

After-sales Service Provided2:

-

Online support

-

After Warranty Service:

-

Online support

-

Certification:

-

CE ISO

-

COLOR:

-

Customers' Demand

open roller mill mixing machine

1- Main features:

1.Materials of Rolls : The roller are made of cast iron alloy (LTGH), whose surface is 75HS, harder than other company,(they are usually 72HS ) .The working surface is well grinded and machined.

2. Reducer: The speed reducer is hardened tooth with class 6 precision, no noise and vibration, safety with higher transmission efficiency.

3.Motor: We always use OMRON,SIMENS ect brand electric parts or you can choice the ordinary brand.

4.Cooling system : (with rotating joint) Universal rotary joints with inner spray pipes with hoses and headers. Piping is complete up to supply pipe terminal , which reduces energy consumption by 40% and high efficiency.

5.E mergency brake device : (brake,emergency button,pull rod) The machine is also equipped with an emergency brake device. When an emergent arises, just draw the safety pull rod or press the emergency button and the machine will stop immediately. It is safe and reliable.

6.Stock bender: it for direct rubber sheet and knife to cut as your need to assemble.then improve the quality of mixing ,and reduce the energy consumption.

XK-160 lab rubber mixing mill

XK-250

XK-360

XK-400

XK-450

XK-560

XK-660

1. The machine is applicable for plasticizing,warming and mixing rubber.

2. The rolls are made of chilled cast iron with vanadium and titanium alloys.The roll face is hard and anti-wear.The internal cavity is processed to make temperature well proportioned on the roll surface.

3. The machine is equipped with an overload protection device to prevent the major components from being damaged due to overloading.

4. The machine is also equipped with an emergency device.When an emergent accident happens,just draw the pull rod,and the machine will stop immediately.It ’ s safe and reliable.

5. The transmission system adopts a hard facing gear reducer,which has a compacted structure with higher transmission efficiency,lower noise and longer service life.

6. The base frame is a complete framework,which is convenient for installation.

| Model | XK-160 | XK-250 | XK-300 | XK-360 | XK-400 | XK-450 | XK-560 | XK-610 |

| Working diameter of F.&B.rolls(mm) | 160 | 250 | 300 | 360 | 400 | 450 | 560 | 610 |

| Working length of F.&B. rolls(mm) | 320 | 620 | 750 | 900 | 1000 | 1200 | 1500 | 2000 |

| Linear speed of F.roll(m/min) | 8.95 | 14.9 | 15.1 | 17.4 | 19.3 | 23 | 28.8 | 27 |

| Linear speed ratio of F.&B. rolls | 1:1.35 | 1:1.1 | 1:1.27 | 1:1.27 | 1:1.27 | 1:1.27 | 1:1.19 | 1:1.23 |

| Maximum Nip(mm) | 4.5 | 10 | 10 | 10 | 10 | 10 | 15 | 15 |

| Nip regulating mode | Manual or electric | |||||||

| Batch capacity(kg/batch) | 1-2 | 10-15 | 15-20 | 20-25 | 25-35 | 30-50 | 50-60 | 120-140 |

| Main motor power(kw) | 5.5 | 15 | 22 | 30 | 45 | 55 | 90/110 | 160 |

| Speed reducer | NGW planetary hardened-gear speed reducer | |||||||

| Overall dimension(mm) |

1120*920 *1350 |

3400*1270 *1620 |

3450*1500 *1550 |

4140*1770 *1700 |

4490*1770 *1750 |

5570*1900 *1750 |

6290*2330 *1780 |

6947*2505 *2494 |

| Weight(kg) | 1200 | 4200 | 5200 | 7600 | 9000 | 11500 | 20400 | 26500 |

1.Q:Are you a trading company or a factory?

A:We are 100% real manufacturer,we have more than 30000 square meters of factory buildings and workshops for producing machines,welcome to visit our factory.

2.Q:Do you have machine warranty?

A:Yes,we have 2 years warranty,however,the using life of our machines is usually more than 10 years.

3.Q:I have special requirement about machines,such as length,diameter,or others,can you meet it?

A:Yes,we can manufacture various non-standard specifications of machines,if you have special requirement,please contact us.

4.Q:I want to purchase your company's machine,can you send me a quotation?

A:Sure,please tell me the model of the machine that you need,I will provide you a suitable price.If you don't know which model suits you,contact me,I will recommend a suitable machine to you.

5.Q:What's your payment term?

A:30% of total value in advance by TT,a further 70% will be paid before loading.

6.Q:What's your MOQ?

A:The MOQ is 1 set,but if you order more than 1 machine,you will get different discounts according to the quantity.

If you have any questions about our machines,

please contact me any time and I'm glad to provide service to you!

How to contact us?

Send your inquiry details in the below,click "Send" now!