- Product Details

- {{item.text}}

Quick Details

-

Design Style:

-

Traditional

-

Place of Origin:

-

Hebei, China

-

Product name:

-

Steel Grating

-

Surface treatment:

-

Zinc Coated

-

Raw material:

-

Carton Steel

-

Advantage:

-

Long Service Life

-

Feature:

-

Durable

Quick Details

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design

-

Application:

-

Office Building

-

Design Style:

-

Traditional

-

Place of Origin:

-

Hebei, China

-

Product name:

-

Steel Grating

-

Surface treatment:

-

Zinc Coated

-

Raw material:

-

Carton Steel

-

Advantage:

-

Long Service Life

-

Feature:

-

Durable

Unveiling the Power of Steel Gratings: A Versatile Solution for Modern Infrastructure

Discover the versatility of steel gratings as a reliable solution for modern infrastructure. Learn about

their various applications, benefits, and frequently asked questions in this comprehensive article.

Introduction:

Steel gratings have emerged as a reliable and versatile solution for modern infrastructure projects. Whether it's for industrial,commercial, or residential use, steel gratings offer exceptional strength, durability, and versatility that make them a preferred choice for a wide range of applications. From providing safe access in industrial settings to enhancing architectural aesthetics in commercial spaces, steel gratings have become an indispensable part of modern construction and engineering.

In this article, we will delve into the world of steel gratings, exploring their various applications, benefits, and frequently

asked questions. So, let's dive in and unveil the power of steel gratings!

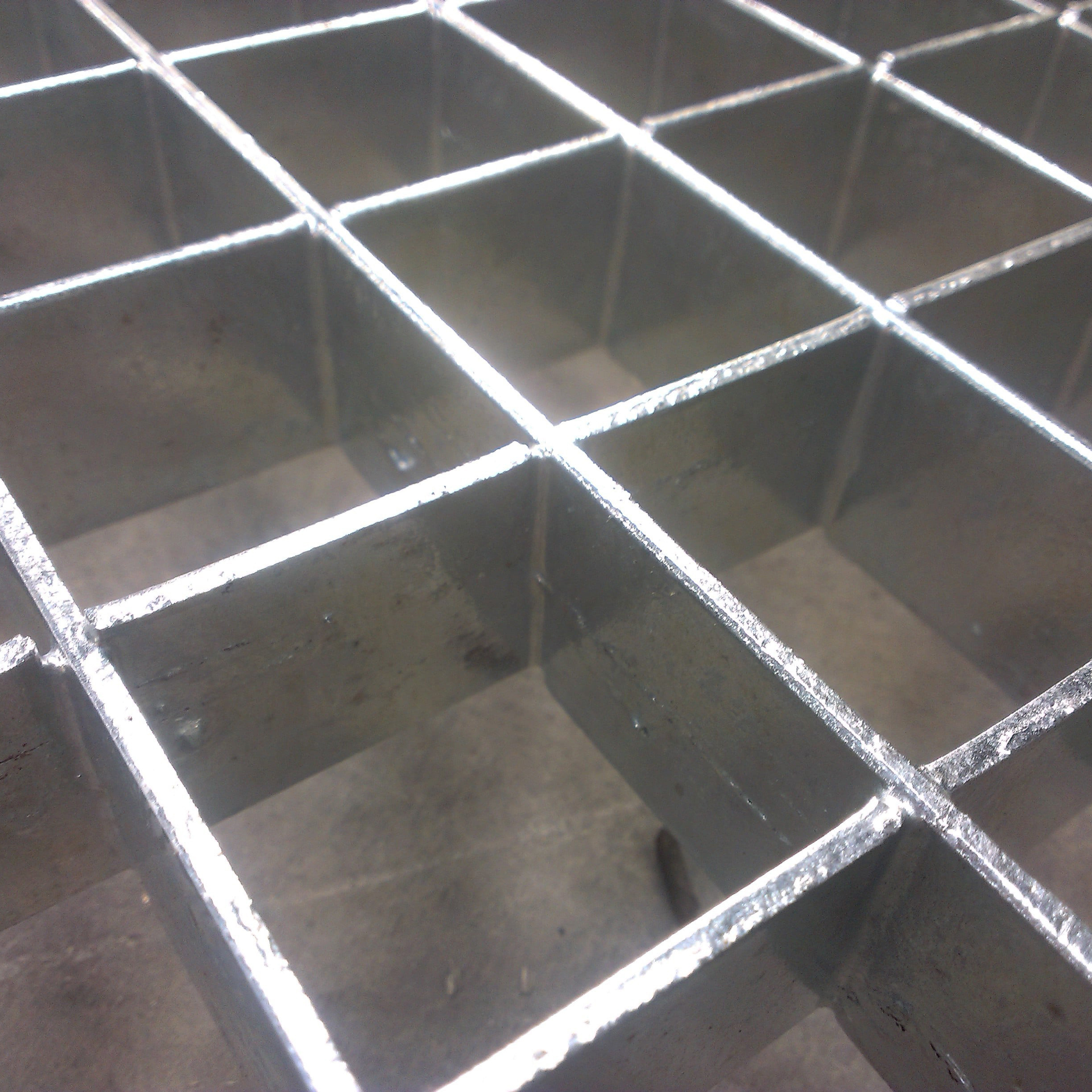

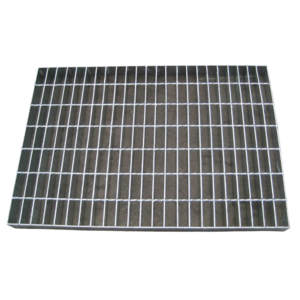

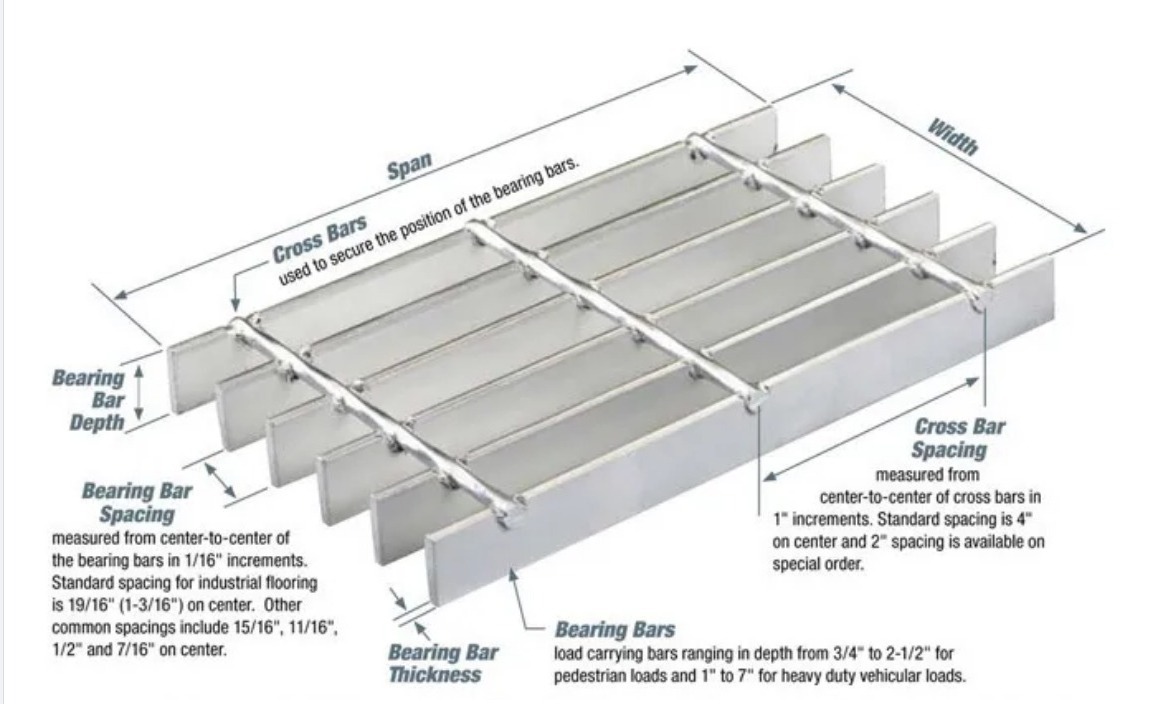

Steel gratings, also known as bar grating or metal grating, are rigid grid-like structures made from steel bars or other metals that are interconnected at regular intervals. These bars are usually welded or locked together to create a sturdy and robust structure that can withstand heavy loads, making them suitable for a wide range of applications.

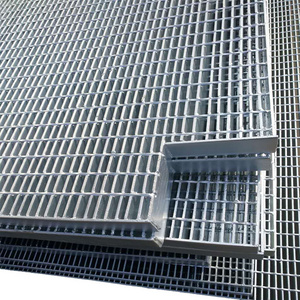

Steel gratings are typically available in various types, including welded steel grating, press-locked steel grating, and riveted

steel grating, each with its own unique features and advantages. Welded steel gratings are made by welding the steel bars together at their intersections, resulting in a strong and durable structure. Press-locked steel gratings are manufactured by interlocking the steel bars with a combination of pressure and heat, creating a smooth and sleek surface. Riveted steel gratings are assembled by riveting the steel bars together with rivets, which provides a traditional and aesthetic appearance.

their various applications, benefits, and frequently asked questions in this comprehensive article.

Introduction:

Steel gratings have emerged as a reliable and versatile solution for modern infrastructure projects. Whether it's for industrial,commercial, or residential use, steel gratings offer exceptional strength, durability, and versatility that make them a preferred choice for a wide range of applications. From providing safe access in industrial settings to enhancing architectural aesthetics in commercial spaces, steel gratings have become an indispensable part of modern construction and engineering.

In this article, we will delve into the world of steel gratings, exploring their various applications, benefits, and frequently

asked questions. So, let's dive in and unveil the power of steel gratings!

Steel gratings, also known as bar grating or metal grating, are rigid grid-like structures made from steel bars or other metals that are interconnected at regular intervals. These bars are usually welded or locked together to create a sturdy and robust structure that can withstand heavy loads, making them suitable for a wide range of applications.

Steel gratings are typically available in various types, including welded steel grating, press-locked steel grating, and riveted

steel grating, each with its own unique features and advantages. Welded steel gratings are made by welding the steel bars together at their intersections, resulting in a strong and durable structure. Press-locked steel gratings are manufactured by interlocking the steel bars with a combination of pressure and heat, creating a smooth and sleek surface. Riveted steel gratings are assembled by riveting the steel bars together with rivets, which provides a traditional and aesthetic appearance.

Applications of Steel Gratings

Steel gratings find extensive applications in various industries and infrastructure projects due to their versatility and

durability. Some of the common applications of steel gratings include:

1. Industrial Platforms and Walkways: Steel gratings are widely used in industrial settings as platforms and walkways for safe and secure access to elevated areas such as mezzanines, catwalks, and stair treads. They provide slip-resistant surfaces, excellent drainage, and ventilation, making them ideal for use in heavy-duty environments such as factories, warehouses, and refineries.

2. Commercial and Architectural: Steel gratings are also used in commercial spaces for architectural purposes to enhance

aesthetics and provide functional solutions. They are commonly used in building facades, sunshades, cladding, and landscaping features to create modern and contemporary designs.

3. Drainage Systems: Steel gratings are used in drainage systems to allow water to flow through while preventing debris and solid particles from entering the system. They are commonly used in trenches, catch basins, stormwater grates, and other applications where effective drainage is required.

4. Transportation: Steel gratings are used in transportation infrastructure such as bridges, highways, and airports for their

high load-bearing capacity and durability. They provide safe and reliable access for vehicles and pedestrians, making them an essential component of modern transportation infrastructure.

5. Security Fencing: Steel gratings are used in security fencing applications where high-security and anti-climbing features are required. They are commonly used in prisons, military bases, airports, and other sensitive areas to provide a robust and

secure barrier.

6. Oil and Gas Industry: Steel gratings are used in the oil and gas industry for various applications, including offshore

platforms, refineries, and petrochemical plants. They are resistant to corrosion and offer high strength and and walkway

solutions. They provide a safe and sturdy walking surface, allowing workers to access elevated areas and traverse

across platforms with ease. Steel gratings are commonly used in industries such as manufacturing, oil and gas, chemical

processing, and transportation, where heavy machinery and equipment are often present.

7. Commercial and architectural applications: Steel gratings are also popular in commercial and architectural spaces for their aesthetic appeal and versatility. They can be used as decorative elements in building facades, sunshades, and screening applications. Steel gratings can also be used as infill panels for railing systems, providing both safety and an attractive design feature.

8. Drainage and trench covers: Steel gratings are frequently used as drainage covers and trench covers in various settings,

including sidewalks, parking lots, airports, and industrial sites. They allow water to drain through while providing a stable

surface for pedestrians and vehicles. Steel gratings used for drainage and trench covers are designed with specialized

patterns and spacing to prevent debris from clogging the drains.

9. Security and safety applications: Steel gratings are often used in security and safety applications, such as perimeter

fencing, machine guarding, and anti-slip flooring. They provide a durable and secure barrier, protecting valuable assets and

preventing unauthorized access to restricted areas. Steel gratings with anti-slip features are commonly used in areas where slip and fall accidents are a concern, such as ramps, staircases, and industrial floors.

10. Customized applications: Steel gratings can also be customized to suit specific project requirements. They can be fabricated in various sizes, shapes, and configurations to fit unique spaces and applications. Customized steel gratings are commonly used in architectural and artistic installations, where aesthetics and design play a crucial role.

Galvanized Steel Grating

Galvanized grating, also called galvanized steel grating or galvanized steel bar grating, refers to the steel bar grating made of mild carbon steel through hot dipped galvanized surface treatment.

Mild carbon steel provides an economical, high strength for uses in most industrial and commercial applications. And hot dipped galvanized surface treatment supplies excellent corrosion resistance performance for durability.

Steel grating is available in various material, such as stainless steel, aluminum, and galvanized steel. Among them, the galvanized steel grating is the most cost effective and economical type with long service life and high load. And it is the most widely used in both industrial, commercial and residential applications.

Mild carbon steel provides an economical, high strength for uses in most industrial and commercial applications. And hot dipped galvanized surface treatment supplies excellent corrosion resistance performance for durability.

Steel grating is available in various material, such as stainless steel, aluminum, and galvanized steel. Among them, the galvanized steel grating is the most cost effective and economical type with long service life and high load. And it is the most widely used in both industrial, commercial and residential applications.

Stainless Steel Grating

Stainless steel grating is regarded as industrial grade bar grating, which is extremely strong, durable and corrosive resistant for all load bearing applications and is primarily used for pedestrian and light vehicle traffic.

* Both in Smooth or serrated surface.

* 304 or 316 grade for choice.

* Wide range of bearing bar sizes and pitches.

* Special discount for large orders.

* Project reference can be supplied for your bid.

* ISO Certificated factory.

* CAD or 3D drawing can be supplied for your design and construction.

* 304 or 316 grade for choice.

* Wide range of bearing bar sizes and pitches.

* Special discount for large orders.

* Project reference can be supplied for your bid.

* ISO Certificated factory.

* CAD or 3D drawing can be supplied for your design and construction.

Aluminum Grating

Aluminum grating is an ideal choice when corrosion-resistant, lightweight materials that do not affect its load capacity and mechanical strength is required. Made of ASTM B221, 6063 or 6061 alloy, aluminum grating has great versatile and durable and is mainly used for platform ceilings and outdoor curtain walls.

* It is lighter than steel grating and has high load carrying capacity.

* Aluminum gratings are made of aluminum alloy featured by cheap, economical and practical.

* Smooth and serrated surfaces are available. Good anti-slip performance for safety protection.

* Excellent corrosion and rust resistance for durability.

* A variety of specifications and styles are available to meet various application environments.

* It is lighter than steel grating and has high load carrying capacity.

* Aluminum gratings are made of aluminum alloy featured by cheap, economical and practical.

* Smooth and serrated surfaces are available. Good anti-slip performance for safety protection.

* Excellent corrosion and rust resistance for durability.

* A variety of specifications and styles are available to meet various application environments.

I Bar Steel Grating

I shape bearing bars supplies lighter weight when the strength is equal to rectangular bar steel grating. I bar steel grating is suitable for both commercial and industrial applications.

* Special I shape bearing bars.

* Lighter weight and high strength.

* Carbon steel, galvanized steel or stainless steel material options.

* Ideal for both commercial and industrial applications.

* Wide range of configurations for choice.

* Special discount for large orders.

* Project reference can be supplied for your bid.

* ISO Certificated factory.

* CAD or 3D drawing can be supplied for your design and construction.

* Special I shape bearing bars.

* Lighter weight and high strength.

* Carbon steel, galvanized steel or stainless steel material options.

* Ideal for both commercial and industrial applications.

* Wide range of configurations for choice.

* Special discount for large orders.

* Project reference can be supplied for your bid.

* ISO Certificated factory.

* CAD or 3D drawing can be supplied for your design and construction.

Serrated steel grating

Serrated steel grating" is a type of steel grating that has serrated or notched edges on the bearing bars. These serrations or notches provide additional slip resistance, making the grating suitable for areas where slip and fall accidents are a concern, such as ramps, staircases, and areas with oily or wet conditions. The serrated edges help improve traction, providing a safer walking surface for pedestrians and workers. Serrated steel grating is commonly used in industrial and commercial applications

where safety is a priority.

where safety is a priority.

Louver Steel Grating

Louver steel grating is a special steel grating, it is made of low carbon steel or stainless steel. In general, it can be made in two ways: welded and press-locked. With the performance of high strength, ventilation, sunshade, not easy to fade in the sun, beautiful and easy to clean and maintain, louver steel grating is widely used in outdoors an

d indoors, such as: sun visor, building facade, walkaway, fence, partitions, railing of stairs and steps and transition between stairs or floors.

FAQ

1. What are the common applications of steel gratings?

Steel gratings are commonly used in various construction and industrial applications, such as industrial floors, platforms, walkways, bridges, ramps, stair treads, mezzanine floors, drainage covers, building facades, sunscreens, and decorative screens.

2. What are the advantages of using steel gratings over other materials?

2. What are the advantages of using steel gratings over other materials?

Steel gratings offer several advantages over other materials, such as high load-bearing capacity, excellent strength and stability, open-grid design for efficient drainage, versatility and customization options, durability and longevity, and cost-effectiveness.

3. How are steel gratings installed?

3. How are steel gratings installed?

Steel gratings are installed by preparing the site, measuring and cutting the gratings to fit the area, anchoring and fixing the gratings to the supporting structure using methods such as welding, bolting, or using clips or clamps.

4. How do I maintain steel gratings?

4. How do I maintain steel gratings?

Steel gratings require regular maintenance, including cleaning to remove dirt and debris, and periodic inspections to check for signs of wear, corrosion, or damage that may require repairs or replacements.

Hot Searches