- Product Details

- {{item.text}}

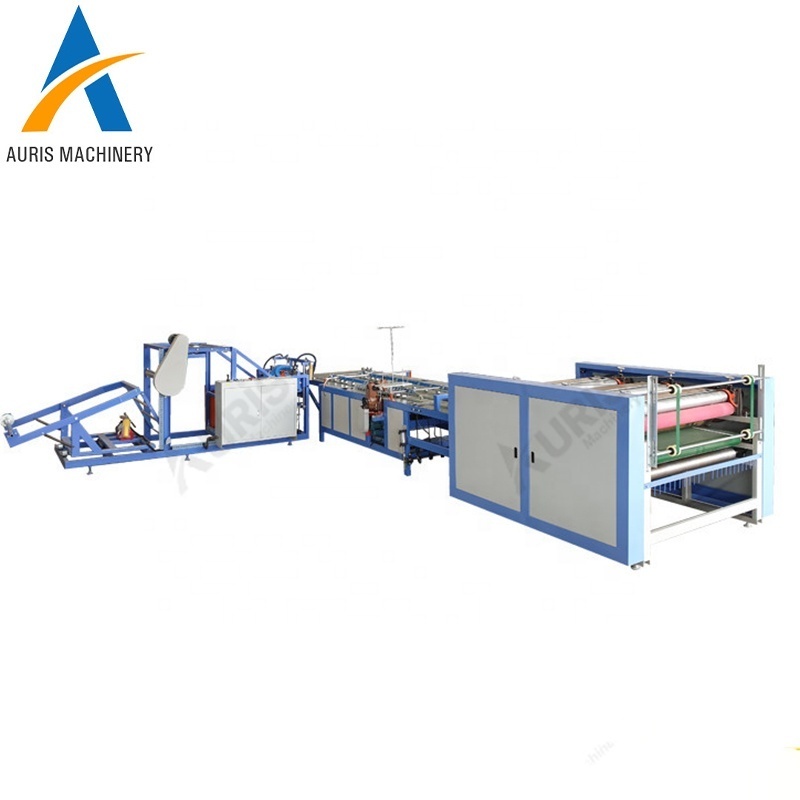

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Auris

-

Model Number:

-

AQF-800

-

Voltage:

-

380V, 50 Hz, three phases

-

Dimension(L*W*H):

-

11800x 5500x 1800mm

-

Weight:

-

3800 KG

-

Product name:

-

woven bag forming machine

-

Application:

-

Cement Bag

-

Bag width:

-

800-1300mm

-

Bag length:

-

1200mm

-

Cutting Type:

-

Heat/Cold

-

Printing colors:

-

1-6 colors

-

Sewing part:

-

Japanese NEWLONG DS-2II

-

Electrical component brand:

-

Schneider

-

Machine frame thickness:

-

10mm

-

Operation:

-

Touch screen

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Cement Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Auris

-

Model Number:

-

AQF-800

-

Voltage:

-

380V, 50 Hz, three phases

-

Dimension(L*W*H):

-

11800x 5500x 1800mm

-

Weight:

-

3800 KG

-

Product name:

-

woven bag forming machine

-

Application:

-

Cement Bag

-

Bag width:

-

800-1300mm

-

Bag length:

-

1200mm

-

Cutting Type:

-

Heat/Cold

-

Printing colors:

-

1-6 colors

-

Sewing part:

-

Japanese NEWLONG DS-2II

-

Electrical component brand:

-

Schneider

-

Machine frame thickness:

-

10mm

-

Operation:

-

Touch screen

Product Description

garbage bag making machine polythene bag cement bag making printing machine

Applicable to slitting various market bags, fertilizer bags, rice bags, is a one-time processing equipment that completes the whole roll of woven bags to finished products at one time.

The machine integrates automatic folding, automatic sewing, printing and automatic material collection. The cutting line is reliable, which can greatly reduce the labor intensity and save personnel.

It has the characteristics of fast speed, easy operation and convenient maintenance. It is an ideal equipment for various market bags and fertilizer bag manufacturers.

The machine integrates automatic folding, automatic sewing, printing and automatic material collection. The cutting line is reliable, which can greatly reduce the labor intensity and save personnel.

It has the characteristics of fast speed, easy operation and convenient maintenance. It is an ideal equipment for various market bags and fertilizer bag manufacturers.

Features of

garbage bag making machine polythene bag cement bag making printing machine

1. Applicable to the processing and packaging of various cement bags, flour bags, feed bags, sugar bags, fertilizer bags and other bags.

2. Fully automated, intelligent operation combined with one person and one machine, the production efficiency is more than doubled.

3. Integrate a variety of processing processes into one, one person can complete all the processes of feeding, feeding, folding, sewing, breaking, receiving, tidying and counting of woven bags, with close cooperation and no interference.

4. Combination with photoelectric detection equipment For the first time, the industry cooperates with photoelectric detection devices on the equipment to intuitively and accurately detect the workflow, with good safety, low consumption of electrodes and easy operation.

5. Adopt digital frequency conversion speed regulation, power electric power is converted into lighting power, and the consumption of electric electrodes is small.

6. According to customer needs, special size, can be customized .

Main parameters

|

Model

|

AMS-QFY-800

|

|

Maximum diameter of the material roll

|

1200mm

|

|

Material width

|

450-800mm

|

|

Cutting length

|

1200mm

|

|

Fold length at bottom of bag

|

20-30mm

|

|

Production capacity

|

25-45pcs/min

|

|

Stitch space

|

7-13mm

|

|

Total power

|

9kw

|

|

Printing color

|

1-4 colors

|

|

Effective print size

|

800x1200mm

|

|

Heating power

|

1kw

|

|

The air consumption

|

0.36M/Minute

|

|

Mechanical dimensions

|

11800x 5500x 1800mm

|

|

The weight of the

|

3800kg

|

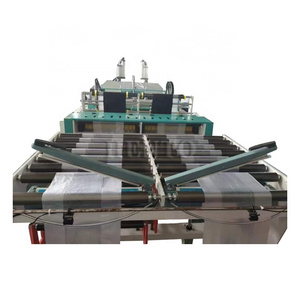

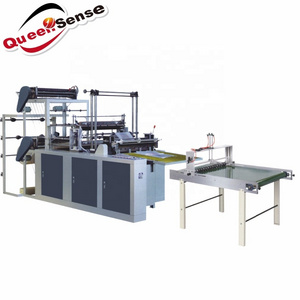

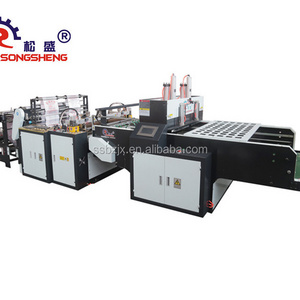

Detailed Images

hot sales product

Contact us

Hot Searches