Each batch of products requires 62 different inspections before shipment, and each item is strictly recorded and archive.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

COOWIN

-

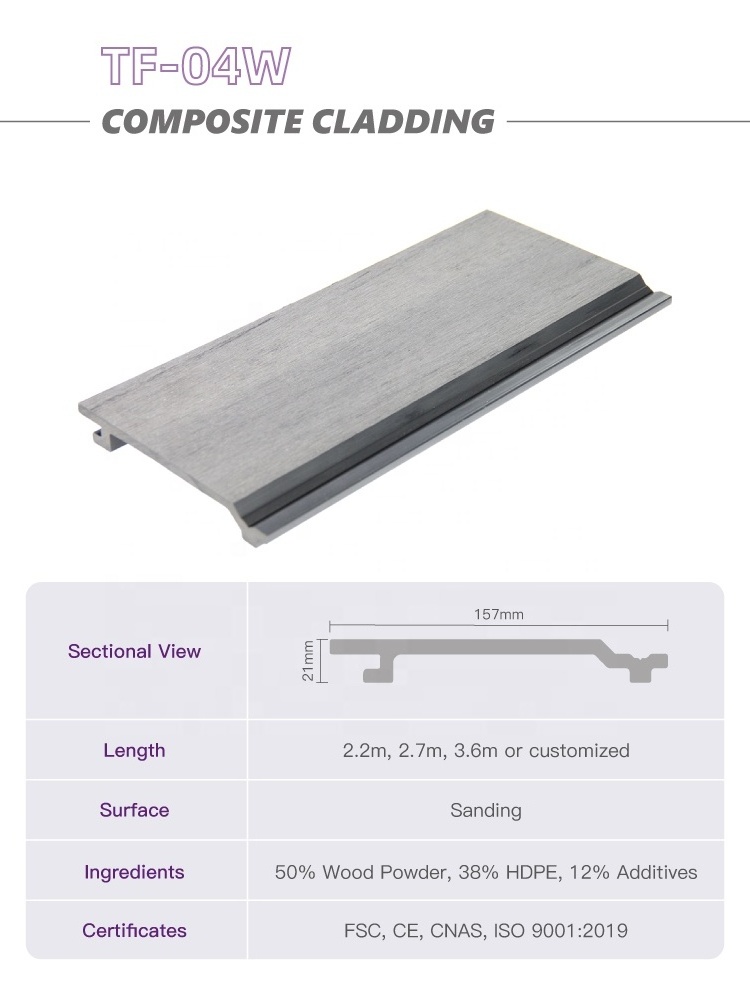

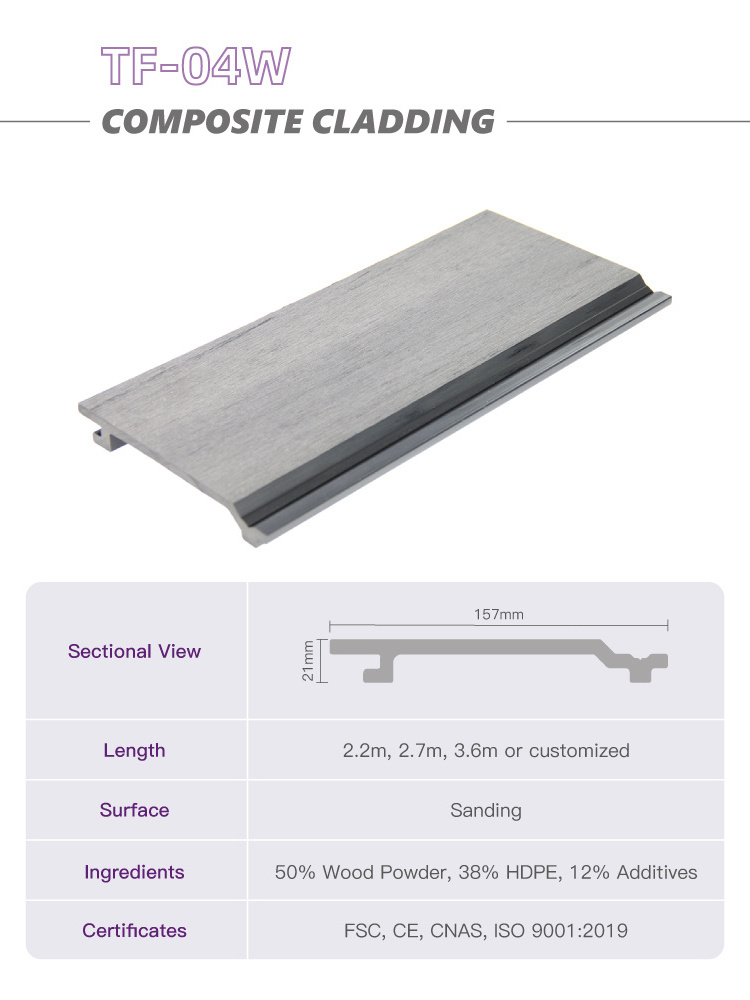

Model Number:

-

TF-04W

-

Product name:

-

Grey Color WPC Wall Panels Anti-UV Outdoor Decoration Board

-

Size:

-

157x21mm

-

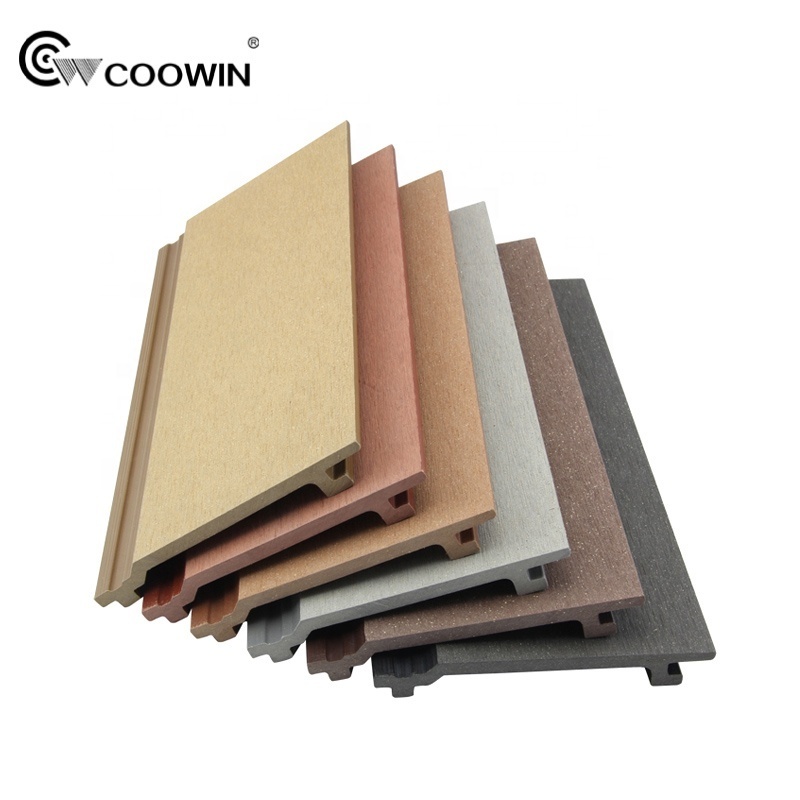

Color:

-

6 standards color, 5 art colors

-

Surface Treatment:

-

Grooved

-

Composition Material:

-

50% Grade A Wood Poplar flour, 38% HDPE, 12% Additive

-

Certificates:

-

ISO 9001:2008, CE, FSC

-

Weather Ability:

-

Weather resistant, suitable from -40℃ to 60℃..

-

Maintenance:

-

Requires no painting, no glue, low maintenance.

-

Export To:

-

North and South America, Europe , Asia, Australia, over 87 countries.

-

Surface:

-

Wood natural feel

Quick Details

-

Project Solution Capability:

-

3D model design

-

Application:

-

Mall

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

COOWIN

-

Model Number:

-

TF-04W

-

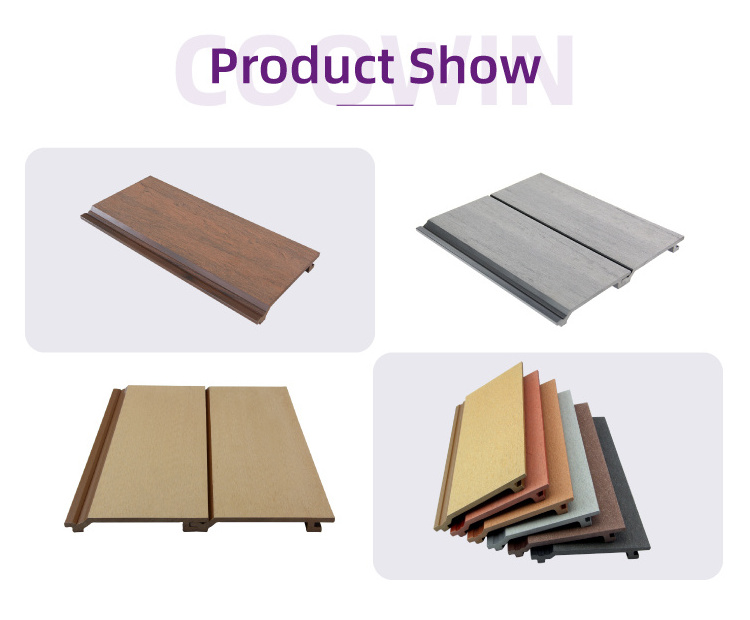

Product name:

-

Grey Color WPC Wall Panels Anti-UV Outdoor Decoration Board

-

Size:

-

157x21mm

-

Color:

-

6 standards color, 5 art colors

-

Surface Treatment:

-

Grooved

-

Composition Material:

-

50% Grade A Wood Poplar flour, 38% HDPE, 12% Additive

-

Certificates:

-

ISO 9001:2008, CE, FSC

-

Weather Ability:

-

Weather resistant, suitable from -40℃ to 60℃..

-

Maintenance:

-

Requires no painting, no glue, low maintenance.

-

Export To:

-

North and South America, Europe , Asia, Australia, over 87 countries.

-

Surface:

-

Wood natural feel

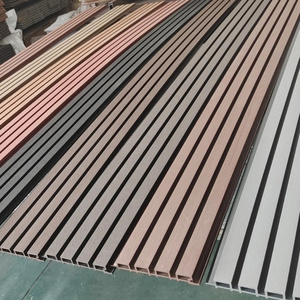

WPC outdoor wall panels WPC wall Siding exterior decoration Cladding

Product Information

Advantage

The advantages of WPC Decking compared from raw wood.

1. Environmental friendly, non-pollution, no toxic chemicals.

2. Waterproof, mildew resistant, corrosion resistant.

3. WPC have good workability and can be shaped using conventional woodworking tools.

4. Recyclable.

5. Good appearance, Look like natural wood.

6. Colorful, less maintenance.

2. Waterproof, mildew resistant, corrosion resistant.

3. WPC have good workability and can be shaped using conventional woodworking tools.

4. Recyclable.

5. Good appearance, Look like natural wood.

6. Colorful, less maintenance.

The contrast of WPC and Timber:

|

Characteristic

|

|

Coowin WPC

|

Timber

|

|

|

Using property

|

Resistance to moisture

|

Waterproof

|

Not Waterproof

|

|

|

|

Resistance to rot

|

Antisepsis

|

Easy to rot,need special treating

|

|

|

|

Resistance to split

|

Never split generally

|

Certin to split ate the effect of weathering

|

|

|

|

Resistance to disortion

|

Infrequent to distort

|

Easy t distort especially outdoor

|

|

|

Application to outdoor

|

——

|

Vary adaptive

|

A few treated-wood is adaptive

|

|

|

Maintenance

|

Painting

|

Need not paint

|

Need to paint periodically to maintain

|

|

|

|

Coloring

|

Have many types of color itself,needn't paint

|

Need paint sometimes

|

|

|

Lifespan

|

——

|

No maintance,Longer life-time

|

Exist with maintance

|

|

|

Form

|

——

|

Can be extruded to many types of forms,and can be made by order

|

Form is simplex

|

|

|

Environmental effects

|

——

|

Can be recycled in 100%

|

Consume woods

|

|

|

Summing-up

|

——

|

The retio of capability to price is large

|

The retio of capability to price is less

|

|

Reliable Performance

RELIABLE PERFORMANCE

As a product for outdoor use, COOWIN has high requirements for product performance. In addition to meeting the basic needs of most of the world, COOWIN’s R&D department has developed special wood-plastic products for extreme weather such as extreme temperatures, high humidity and strong corrosiveness to meet the needs of special application.

|

Physical and Chemical Properties

|

|

|

||

|

Item(s)

|

Test Result(s)

|

Test Method(s)

|

||

|

Density

|

1.33g/cm3

|

ASTM D792-00

|

||

|

Moisture Content

|

0.2%

|

ASTM D7031-11 Section 5.15

ASTM D4442-16 Method B |

||

|

Screw withdrawal test

|

3353N

|

ASTM D7032-17 Section 5.5

ASTM D1761-12 |

||

|

Impact Resistance

|

>133J

|

ASTM D4495-16

|

||

|

Specific Gravity

|

1.31

|

ASTM D7031-11 Section 5.14

ASTM D792-13 Method A |

||

|

Shore Hardness

|

D/70/1

|

ASTM D2240-15

|

||

|

Mouldproof level

|

0[1]

|

ASTM G 21-15

|

||

|

Formaldehyde Emission

|

0.02ppm[2]

|

ASTM D6007 -14

|

||

|

Soluble heavy metal

|

ND[3]

|

ASTM F963- 16(Clause 8.3)

|

||

|

Fire-Proof Level

|

Bf1

|

EN ISO 9239-1:2010

EN ISO 11925-2:2010+AC:2011 |

||

|

[1] Mold rating standard: 0 — No mildew or discoloration on the surface

[2] 1 ppm = 1 mg/kg = 0.0001% [3] ND = Not detected ( < Method detection limit ) |

|

|

||

Quality Control

Product physico-chemical properties, treatment processes standard, package completeness and cleanliness......

COOWIN products all have passed

SGS, CE, ISO9001, FSC

certification.

Packing and Shipment

Sample

FAQ

Q

:

Is the wall/decking installlation difficult?

A:

Actually the installation is quite easy, both wall panel and decking, only require simple tool like electric drill, clips and screws. Customers can finish the installation quite quickly, usually 2 person can finish

about 50 sqm wall panel/decking.

Q:

What is your deliver time?

A

:Usually 10-15 days for one 20ft container(nearly 850 sqm goods), this time can be reduced to 7 days if the order is regular, so that we could arrange the product works in advance.

Q:

Can I mix 2 color in one order?

A:

Yes, you can! But if the quantity less than 100 sqm for one color, we have to charge extra set-up fee. We are a direct factory and the more colors we choose, the more cost including materials and labour we have to add, we have to control the product cost and hope customer can understand this.

Q:

Are wood plastic composite products environmentally friendly?

A:

Yes. Because WPC will not splinter, warp or fade the way wood does, it dramatically reduces the wasteful cycle of repair and replacement and eliminates the frequent application of environmentally harmful paint, sealers and stains.

Why Choose Us

COOWIN GROUP has been in wood plastic composite material industry since 2000.

The manufacture base concentrate product R&D, production and supporting service.

Product series includes composite decking, wall cladding, fence, railing, gallery, etc which have exported to more than 90 countries and regions around the world.

The manufacture base concentrate product R&D, production and supporting service.

Product series includes composite decking, wall cladding, fence, railing, gallery, etc which have exported to more than 90 countries and regions around the world.

In order to ensure high-quality standard continuous production and R&D of new products, COOWIN's granulation, extrusion and post-processing workshops have adopted customized advanced production equipment and implement professional production processes.

From material selection to finished product, the product will be screened and recorded through various processes, and packaged after dust-free treatment. COOWIN has a professional cargo loading and transport team that guarantees the smooth delivery of every shipment.

COOWIN has complete and rigorous testing methods and processes. Every member of quality control team is strictly selected and has more than 10 years work experience .

From raw materials to finished product shipments, the COOWIN quality control team never missed any detail.

Good quality is not only for appearance, but also for every innermost part of the product. That’s what COOWIN quality control team always insist on.

From raw materials to finished product shipments, the COOWIN quality control team never missed any detail.

Good quality is not only for appearance, but also for every innermost part of the product. That’s what COOWIN quality control team always insist on.

Hot Searches