- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1.5

-

Voltage:

-

380V 220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Chunlai

-

Dimension(L*W*H):

-

2000x900x2000mm

-

Weight:

-

700 KG

-

Filling range:

-

100-1000ml, customize

-

Filling speed:

-

30-40bottles/min, customize

-

filling equipment:

-

bottle filling machine

-

Filling material:

-

liquid, paste, cream

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

500-3000 bottles per hour

-

Packaging Material:

-

Plastic, Paper

-

Filling Material:

-

Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

1.5

-

Voltage:

-

380V 220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Chunlai

-

Dimension(L*W*H):

-

2000x900x2000mm

-

Weight:

-

700 KG

-

Filling range:

-

100-1000ml, customize

-

Filling speed:

-

30-40bottles/min, customize

-

filling equipment:

-

bottle filling machine

-

Filling material:

-

liquid, paste, cream

-

Certification:

-

CE

Product Description

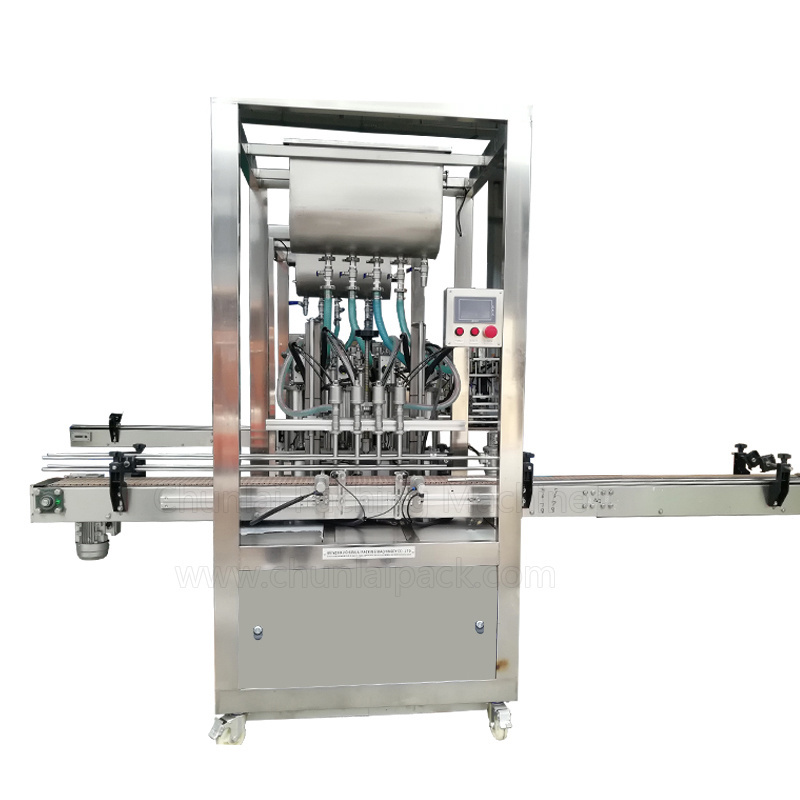

Automatic Filling Machine

Milk Water Juice Chocolate Beverage Liquid Flow Gravity Linear Pressure Bottle Filling Machine

Application:

ZX Series filling machine is widely used for filling all kinds of fluid daily chemical industry, food, medicine, oil. For example liquid, milk, juice, water, shampoo, shower gel, edible oil, pesticides, fruit juice, Lubricating oil, liquid soap, disinfectant, detergent,honey, not very sticky liquid or other materials.

Operating principle

By the reciprocating motion of the pistons in the material cylinders of the Filling Machine, negative

pressure produces in the front chamber of the cylinder so that material could be pumped. The stroke of the cylinder is controlled by a signal valve so as to adjust filing amount and to achieve accurate filling results.

pressure produces in the front chamber of the cylinder so that material could be pumped. The stroke of the cylinder is controlled by a signal valve so as to adjust filing amount and to achieve accurate filling results.

Features:

The Filling Machine with extra functions is designed and manufactured by our factory with reference to the same kind of foreign machines. This machine is simpler and easier in operation, error correction, adjustment, cleaning and maintenance.

With automatic transmission, automatic filling, no bottle no filling, bottle positioning, prevent drip, lifting filling, and other functions. Can be equipped with protective cover.

The part contacting materials is made of 304 stainless steel.

Material contact parts can be customized SS316.

can install hopper. Hopper can be installed liquid level automatic control system

Line include following:

1. Workflow: bottle unscrambling→bottle washing (optional)→filling→adding dropper/(adding plug, adding cap)→screw capping→self adhesive labeling→ribbon printing (optional)→shrink sleeve labeling (optional)→inkjet printing (optional)→bottle collecting (optional)→cartoning (optional)

1. Workflow: bottle unscrambling→bottle washing (optional)→filling→adding dropper/(adding plug, adding cap)→screw capping→self adhesive labeling→ribbon printing (optional)→shrink sleeve labeling (optional)→inkjet printing (optional)→bottle collecting (optional)→cartoning (optional)

|

Model

|

ZX-2

|

ZX-4

|

ZX-6

|

||

|

Filling heads

|

2

|

4

|

6

|

||

|

|

can be customized 8, 10, 12 heads

|

|

|

||

|

Powe supply

|

220/110V 50/60Hz

|

|

|

||

|

Power

|

500W

|

800W

|

1000W

|

||

|

Air pressure

|

0.4-0.6 MPa

|

|

|

||

|

Filling speed

|

4-16 bottles/min

|

8-32 bottles/min

|

12-48 bottles/min

|

||

|

Filling accuracy

|

≤±1.5

|

|

|

||

|

Filling volumes range

|

5-15ml 20-50ml 50-500ml 500-1000ml 1000-3000ml 1000-5000ml

|

|

|

||

|

Conveyor line length

|

1.5-2M

|

|

|

||

Optional Configuration

Options:

Mixing tank

Level control for tank

Double jacket tank

Plastic lid applicator or screw-on lid capper

Discharge conveyor

Inkjet coder for batch, lot number or date coding

Color ribbon date printer for roll film

Plexiglass cover

Servo-Drives

Clean-in-Place (CIP) system

Mixing tank

Level control for tank

Double jacket tank

Plastic lid applicator or screw-on lid capper

Discharge conveyor

Inkjet coder for batch, lot number or date coding

Color ribbon date printer for roll film

Plexiglass cover

Servo-Drives

Clean-in-Place (CIP) system

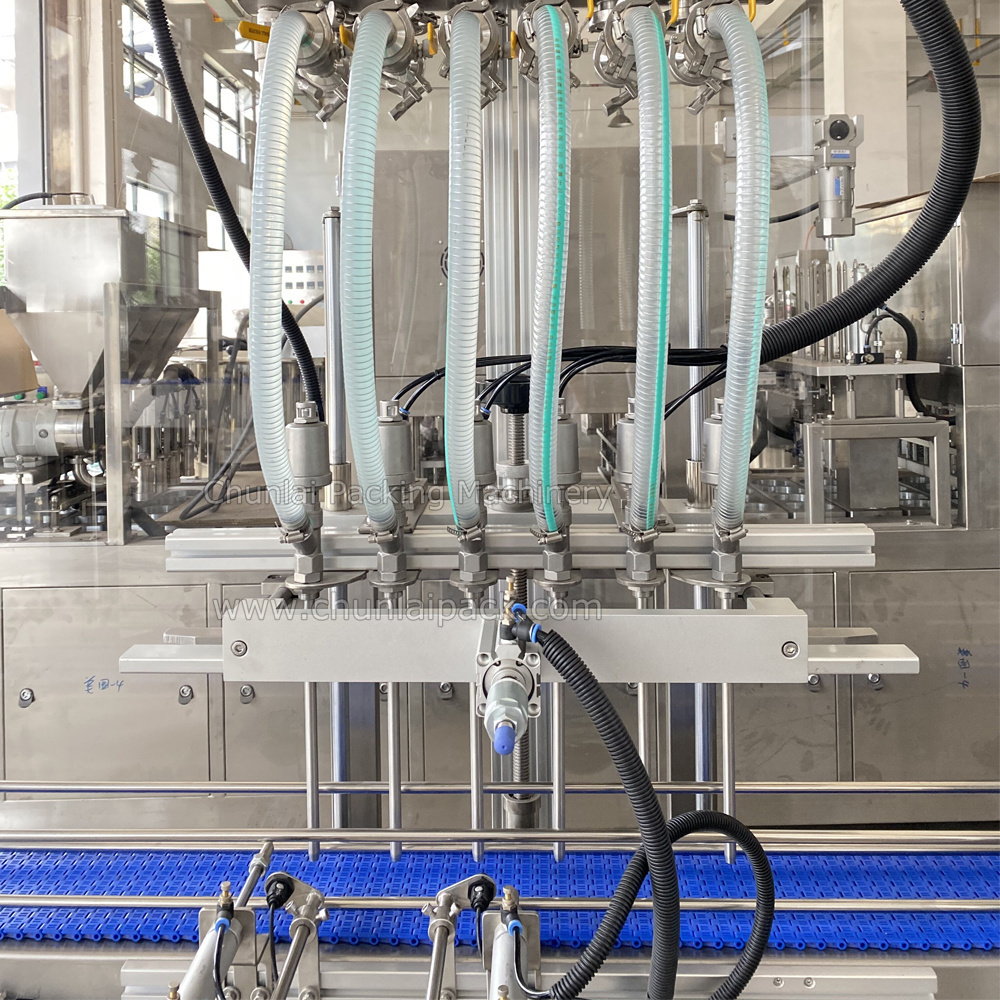

Details Images

without plexi-glass cover

with plexi-glass cover

2 heads piston filling

4 heads piston filling

6 heads gravity filling

6 heads piston filling

8 heads piston filling

10 heads gravity filling

Can be equipped with bottle collection table, capping, labeling machine

rotary feeding table

capping machine

labeling machine

|

Scope Of Application

|

Scope Of Application

|

|

||

|

Filling for liquid ,paste,granule,powder,and so on.

Sealing for cup,bottle,bowl,tray,can,jar,bucket etc...

|

|

|

||

|

Yogurt /Milk/Chocolate

Filling Sealing Machine |

Water

Filling Sealing Machine |

Juice

Filling Sealing Machine |

||

|

Jelly/Pudding

Filling Sealing Machine |

Jam

Filling Sealing Machine |

Sauce

Filling Sealing Machine |

||

|

Instant Noodles

Sealing Machine |

Tofu/Beancurd

Sealing Machine |

Coffee

Filling Sealing Machine

|

||

|

Lunch box

Sealing Machine |

Frozen Food/MAP

Packaging Machine |

Potato Chips Canister

Sealing Machine |

||

|

Porridge

Filling Sealing Machine |

Plastic Jar

Sealing Machine |

Plastic Bucket

Sealing Machine |

||

|

Wet Wipe Can

Sealing Machine |

Dehumidifier Box

Filling Sealing Machine |

Cosmetic/Detergent

Filling Sealing Machine |

||

Hot Searches