Full operation is finished. One worker for one machine.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

3kw/h

-

Dimension(L*W*H):

-

2.2m*1.2m*2.5m

-

Weight:

-

1000 kg

-

Raw material:

-

PE Coated Paper

-

Usage:

-

Food Packing

-

Machine for:

-

Paper Lunch Box PRODUCE

-

Keyword:

-

Lunch Box Forming Machine

-

Finished Products:

-

Paper Cup Paper Bowl,Lunch food box

Quick Details

-

Production Capacity:

-

30~50time/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

XIAOHAI

-

Voltage:

-

380V

-

Power:

-

3kw/h

-

Dimension(L*W*H):

-

2.2m*1.2m*2.5m

-

Weight:

-

1000 kg

-

Raw material:

-

PE Coated Paper

-

Usage:

-

Food Packing

-

Machine for:

-

Paper Lunch Box PRODUCE

-

Keyword:

-

Lunch Box Forming Machine

-

Finished Products:

-

Paper Cup Paper Bowl,Lunch food box

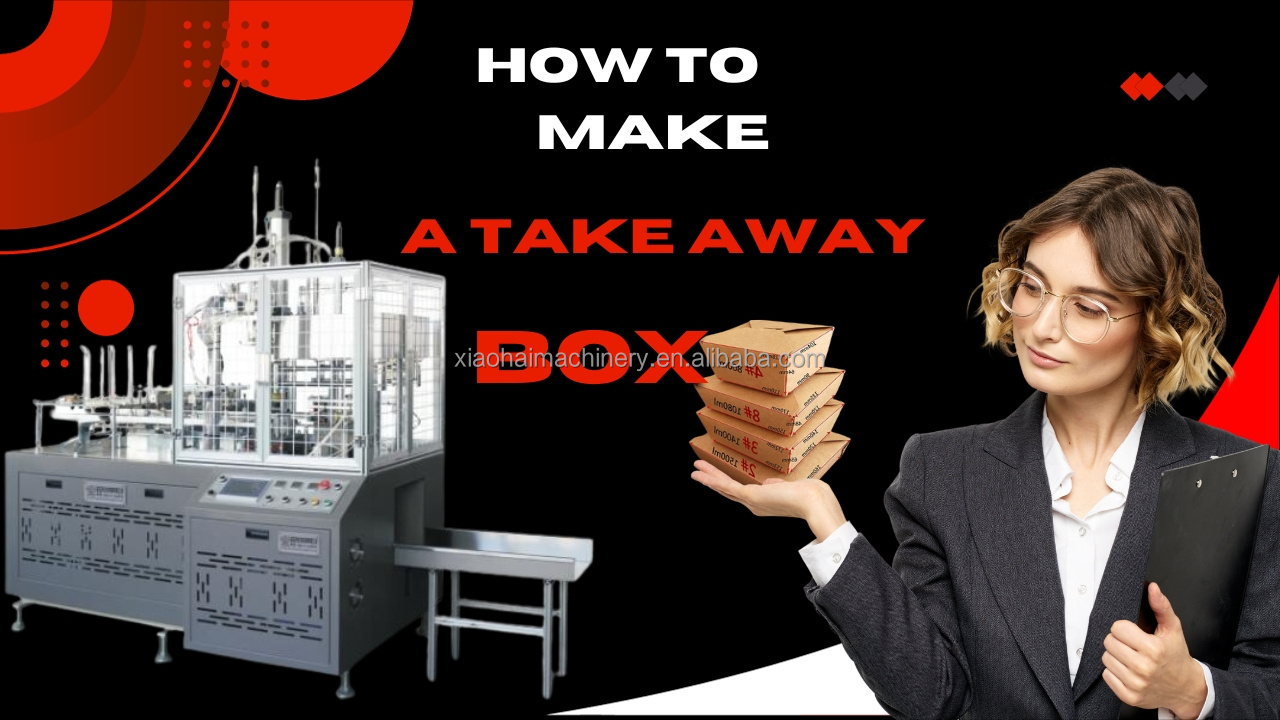

Products Description

Machine Advantages:

Fully Automatic Intelligent papepr box for max grid 2 compartment take away paper lunch fast food box forming making machine is with the advantages of high speed and convenient operation.

This model uses self-contained hot air generator for single PE coated paper. It is used to produce disposable paper lunch boxes through automatic feeding, heating (with hot air generating device), hot press forming (four corners of bonded lunch boxes), automatic collection, and microcomputer control. Paper lunch boxes, cake tray, food packaging boxes, etc.

The current working speed of the equipment is the fastest 50 times/minute. It has automatic systems such as feeding monitoring, paper feeding monitoring, forming monitoring, and collection monitoring. If there is a fault, the machine will stop and alarm.

Fully Automatic Intelligent papepr box for max grid 2 compartment take away paper lunch fast food box forming making machine is with the advantages of high speed and convenient operation.

This model uses self-contained hot air generator for single PE coated paper. It is used to produce disposable paper lunch boxes through automatic feeding, heating (with hot air generating device), hot press forming (four corners of bonded lunch boxes), automatic collection, and microcomputer control. Paper lunch boxes, cake tray, food packaging boxes, etc.

The current working speed of the equipment is the fastest 50 times/minute. It has automatic systems such as feeding monitoring, paper feeding monitoring, forming monitoring, and collection monitoring. If there is a fault, the machine will stop and alarm.

|

Model

|

ZF-B

|

|

Max size

|

600 x550mm

|

|

Production capacity

|

30-50 times/min(Actual production according to product size)

|

|

E-power voltage

|

380V 50HZ (can be changed)

|

|

Suitable Material

|

200-600g/m2 PE (PE Coated paper)

|

|

Total Power:

|

3KW

|

|

Total Weight:

|

1T

|

|

Machine Size:

|

2200x 1200 x 2500 mm

|

|

Working Air Source:

|

Air pressure 0.4-0.5Mpa (Need to buy compressor)

|

Details Images

paper feeding

HEATING BLOWER DEVICE TO HEAT THE PE COATED PAPER

BOX MOULD

FULLY ALUMINUM MOULD,CAN USE 100 YEARS

PAPER BOX AFTER MOULD FORMING

JUST SO EASY

Finished box comes out by conveyor belt

Hot Searches

![[XUANHAI] ZF-B Full automatic multi grid 1 2 3 4 compartment take away paper lunch fast food box forming making machine](https://cdn.bestsuppliers.com/seo_products_img/xiaohaimachinery/375a9c675c9e3f449917fe9996bfb690.jpg!/rotate/180)

![[XUANHAI] ZF-B Full automatic multi grid 1 2 3 4 compartment take away paper lunch fast food box forming making machine](https://cdn.bestsuppliers.com/seo_products_img/xiaohaimachinery/36999805141d3d9e818ce99fd659e561.jpg!/rotate/180)

![[XUANHAI] ZF-B Full automatic multi grid 1 2 3 4 compartment take away paper lunch fast food box forming making machine](https://cdn.bestsuppliers.com/seo_products_img/xiaohaimachinery/9ed141dae9a73cfeaa6bd9966756e450.jpg!/rotate/180)

![[XUANHAI] ZF-B Full automatic multi grid 1 2 3 4 compartment take away paper lunch fast food box forming making machine](https://cdn.bestsuppliers.com/seo_products_img/xiaohaimachinery/546a59295d2e3493bafe8aa12ad10356.jpg!/rotate/180)