- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

4000

-

Dimension(L*W*H):

-

1158*639*1850(mm)

-

Weight:

-

309 kg, 309kg

-

Hopper capacity:

-

125L

-

Hopper Capacity:

-

75kg

-

Dehumidifying Air Quantity:

-

100cbm/hr

-

Drying Temperature:

-

70~180℃

-

Drying hopper type:

-

Double-wall stainless steel with thermal insulation material

-

Working System:

-

Drying + Dehumidifying + Loading(all in one)

-

Dehumidifier Dew Point:

-

-45℃

-

Demensions:

-

1158L*639W*1850H (mm)

-

Item Name:

-

Professional manufacture of dehumidifier humidity removing machine

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WOLTER

-

Voltage:

-

220V/380V

-

Power:

-

4000

-

Dimension(L*W*H):

-

1158*639*1850(mm)

-

Weight:

-

309 kg, 309kg

-

Hopper capacity:

-

125L

-

Hopper Capacity:

-

75kg

-

Dehumidifying Air Quantity:

-

100cbm/hr

-

Drying Temperature:

-

70~180℃

-

Drying hopper type:

-

Double-wall stainless steel with thermal insulation material

-

Working System:

-

Drying + Dehumidifying + Loading(all in one)

-

Dehumidifier Dew Point:

-

-45℃

-

Demensions:

-

1158L*639W*1850H (mm)

-

Item Name:

-

Professional manufacture of dehumidifier humidity removing machine

plastic resin dryers / all-in-one dehumidifying dryer

1. Manufacture

2. Latest Japanese technology

3. Quality warranty

4. Easy operate

5. Different models

WDD-L series all-in-one dehumidifying dryergather dehumidifying, drying, and two-stage conveying into one single unit, is very suitable for drying engineering plastics materials with hygroscopicity such as PA, PC, PBT, PET, ABS. It has dew-point of below -45℃ ~-50℃. It is combined with honeycomb rotor and down blowing fully stainless steel euro hopper dryer, adopted P.I.D temperature control. LCD touch screen and dew point monitor as optional.

3 in 1

Features of WOLTER Dehumidifying Dryer

1. WOLTER Dehumidifier can reach a

stable dew-point of less than -45℃.

2.

Closed-loop conveying

device eliminates the possibility of moisture regain during material conveying.

3.

Hot air recycler equipped as standard,

featuring energy saving, no exhaust of hot air and dust, and environmental protection.

4.

Dual-hopper structure enhances thermal insulation

and achieves higher energy saving rate. It maintains a steady temperature and increase drying efficiency.

5. Suitable for use on

engineering plastic materials with strong absorption ability

such as PA, PC, PBT, PET, etc.

6

. Integration of three functions in one machine,

namely dehumidifying, drying and two-section material conveying. Three-section or four-section material conveying is also optional.

7. Equipped with material conveying, recycling and regenerating

imported filters

to keep the key components such as the fan and honeycomb from dust contamination.

8. The conveying system contains a

material cut-off valve

to make sure no remains in the tube.

9) A thoughtful

multiple security device

built in.

10)

Micro-computer control panel,

easy to operate and clear fault code display.

Optional

Dew-point Monitor (Real-time check)

Dew-point Monitor (Portable)

Two-stage Conveying as standard, while Multi-stage Conveying is optional.

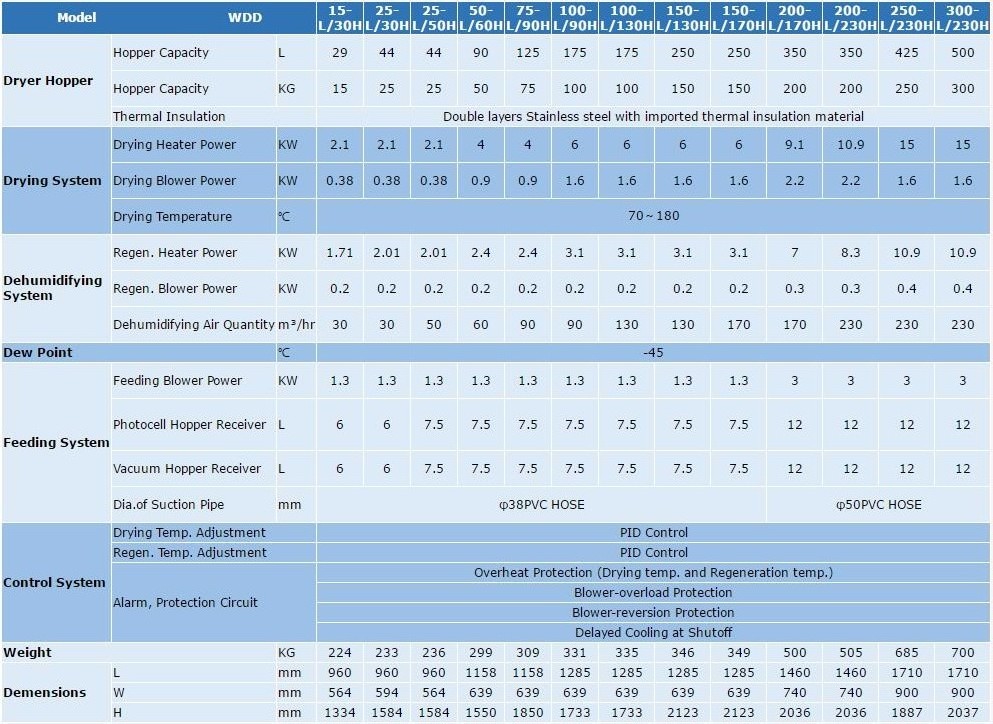

Specifications of WOLTER Dehumidifying Dryer (Full-integral design)

WOLTER all-in-one Dehumidifying Dryer (Semi-integral design)

Working Principle

Dehumidifying: damp and hot air from dry material barrel is blown into rotor after cooled. Moisture from the air is absorbed by rotor and is then adsorbed by regeneration heating air. Two strands of airflow function on the rotor. And with the rotation, moisture from the air is absorbed and expelled after absorbed regeneration air to form stable low dew-point air, which is dried to the drying temperature and then is blown into material barrel to closed circle to dry material.

Suction: material is absorbed into barrel from storage barrel or other storage containers. When the magnetic reed switch detects no material, suction motor runs to produce vacuum inside vacuum hopper. Raw material in storage barrels is absorbed into suction hopper due to air pressure difference. When the time is completed, suction motor stops. Raw materials drop into drying hopper barrel due to gravity. The dried raw material after dried from is taken out to the hopper with photosensor installed on mounding machine or other hopper form frying hopper barrel.

What is honeycomb rotor?

The main part of honeycomb rotor is made by ceramic fiber and organic additives, sintered under high temperature with molecular sieve or silica gel as basic material to bond together with inside of honeycomb to form the honeycomb-like structure. Unlike common dessicant or rotary molecular sieve, then, when aging, will produce dust, followed by process air to drying hopper, to pollute plastic material. Honeycle rotor offers unlimited long service life and can be cleaned and not like usual dessicant which is easy to get saturated or requiring regular replacement. The moisture of return air is quickly absorbed by molecular sieves when passing through numerous holes within honeycomb rotor. So when coming out of rotor, can form low dew-point dry air. Regenerating and dehumidifying have similar principle and run simultaneously. The only difference is that the two process winds are in opposite direction.

WOLTER's Honeycomb Rotors adaopt America UPO Molecular Sieve as adorption mateiral, with excellent dehumification performance.

Advantages:

1. Low dew-point

2. Pollution-free

3. Unlimited long service life.

Dew-point Comparison

Connection Diagram

For serving one machine: Two-stage Conveying System (Standard)

For serving two machines: Three-stage Conveying System (Optional)