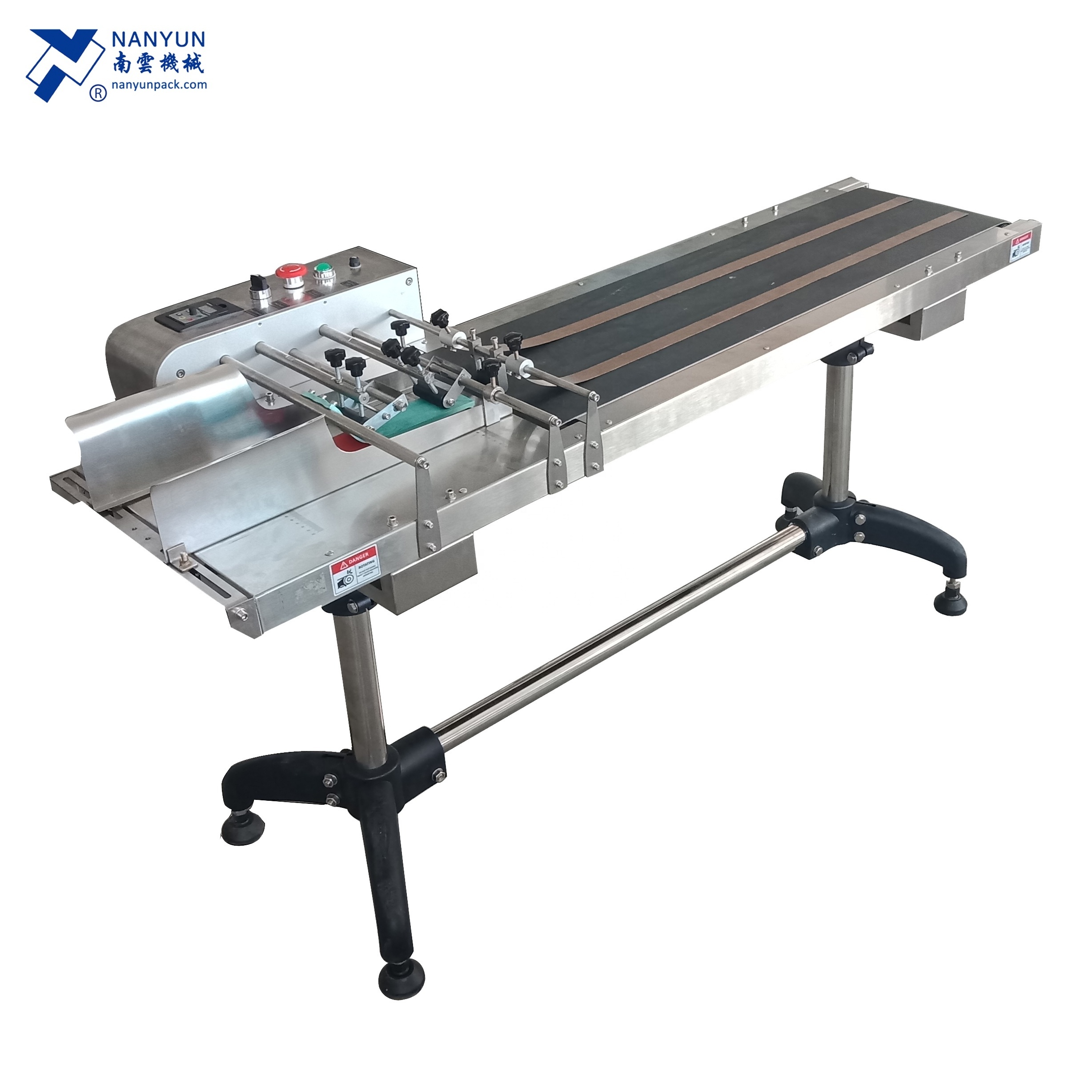

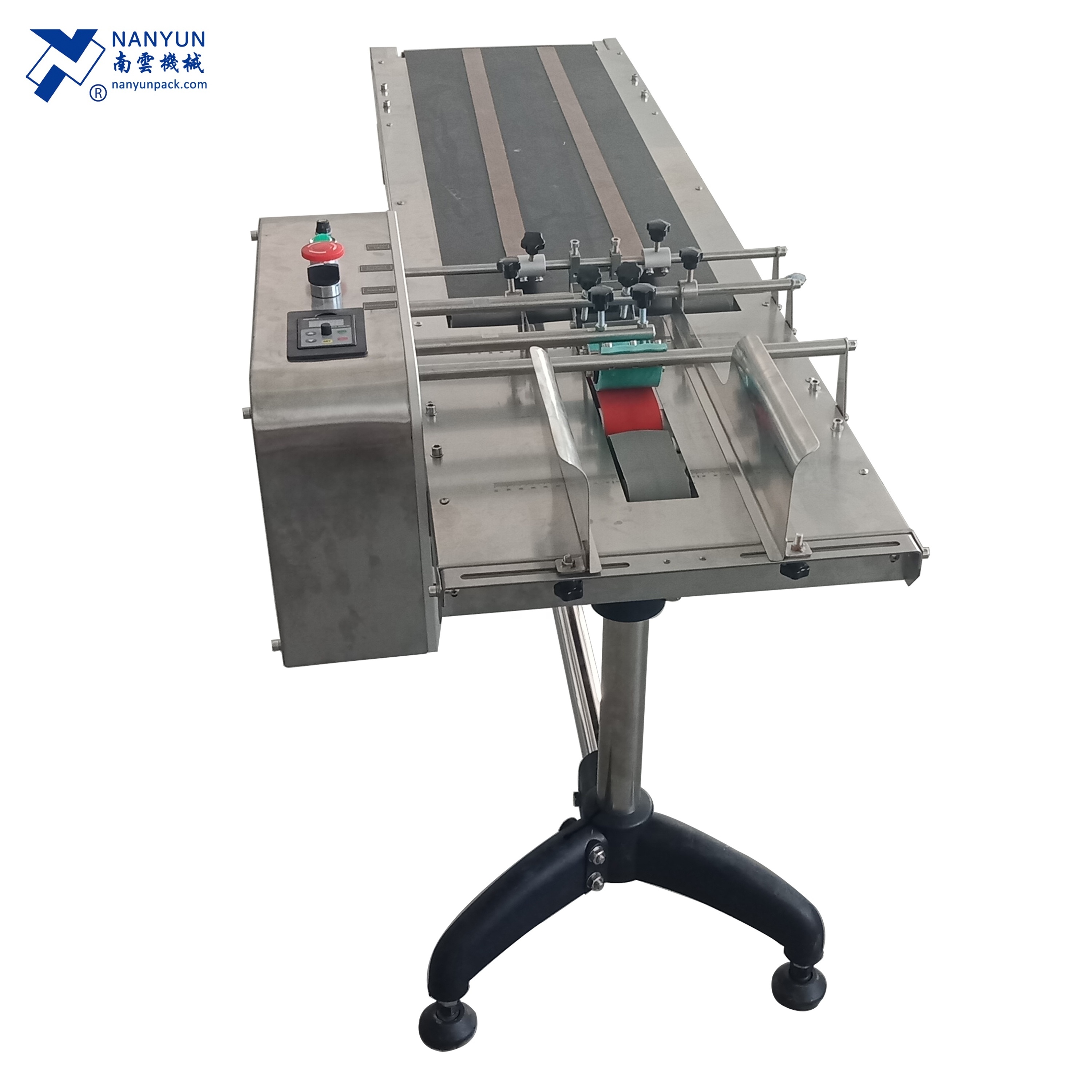

This paging system can automatically separate stacks of bags and convey single piece onto the conveyor belt so as to facilitate label applicator to stick each sticker onto bags and thus reduce the trifles of manual paging to improve labeling efficiency.

This is a feeder and dispenser system which feeds

labels, pouch, cards, plastic bags, sheet paper or other flat objects

at high speed on the conveyor. It

automatically separate/split/divide stacks

of pouches into single piece and deliver to the conveyor belt so as to facilitate ink-jet printer, laser coding machine to spray batch number, logo, anti-fake mark, pattern, QR, and bar code on packages. It also is

good auxiliary equipment for label applicator to finish accuracy and high efficiency labeling working.

How does it work?

Using the most advanced paging technology, bunch or

stack of products are placed in the feeding tray

in this machine and

get fed by a rotating friction wheel

,

the bottom bag will get fed first

. The fed bag then moved forward by chains & rubber belt from one side to the other end side.