- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/ 380V 50Hz

-

Dimension(L*W*H):

-

1360*1670*850

-

Weight:

-

450 kg

-

Marketing Type:

-

Hot sale product

-

Application:

-

Fish Farm

-

Name:

-

Fish Feed Pellet Extruder

-

Color:

-

Clients' Requirement

-

Package:

-

Wooden Case

-

Other name:

-

Animal Feed Pelletizing Machine Mill

-

Processing Types:

-

Fish Feed Processing Line

-

Spare parts:

-

Screw +Sleeve Mold

Quick Details

-

Max. Capacity:

-

150kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Chinese famous brand

-

Voltage:

-

220v/ 380V 50Hz

-

Dimension(L*W*H):

-

1360*1670*850

-

Weight:

-

450 kg

-

Marketing Type:

-

Hot sale product

-

Application:

-

Fish Farm

-

Name:

-

Fish Feed Pellet Extruder

-

Color:

-

Clients' Requirement

-

Package:

-

Wooden Case

-

Other name:

-

Animal Feed Pelletizing Machine Mill

-

Processing Types:

-

Fish Feed Processing Line

-

Spare parts:

-

Screw +Sleeve Mold

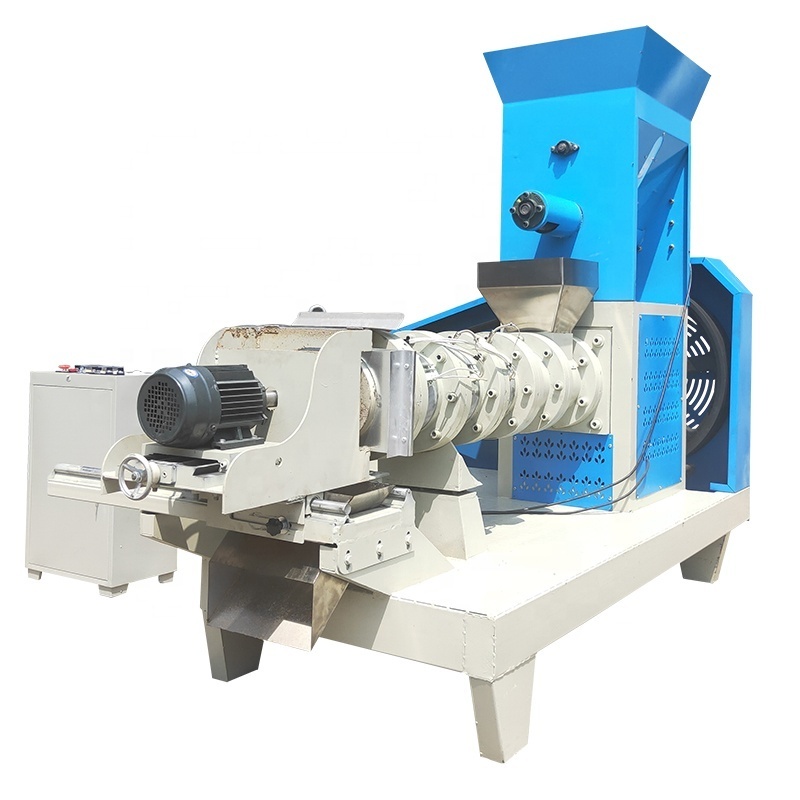

Product Overview

Feed pellet Extruder

Brief Introduction

1. This machine is applicable to frog farmers, fish farmer, pet feed farmer, small and medium feed mill factory, and research

institution.

2. It is used to produce aquatic feed.

1. This machine is applicable to frog farmers, fish farmer, pet feed farmer, small and medium feed mill factory, and research

institution.

2. It is used to produce aquatic feed.

|

Model

|

Efficiency(kg/h)

|

Power(kw)

|

Spiral diameter(mm)

|

Weight(kg)

|

Packing size

|

||||

|

DGP-40B

|

40-50

|

5.5(220V/380V)

|

Φ40

|

350

|

1.36*1.60*0.85m

|

||||

|

DGP-60B

|

120-150

|

15

|

Φ60

|

450

|

1.36*1.67*0.85m

|

||||

|

DGP-70B

|

180-200

|

18.5

|

φ70

|

490

|

1.36*1.67*0.85m

|

||||

|

DGP-80B

|

250-300

|

22

|

φ80

|

600

|

1.36*1.95*0.84m

|

||||

|

DGP-90B

|

400

|

30

|

φ90

|

800

|

1.8*2.6*1.15m

|

||||

|

DGP-100B

|

500

|

37

|

φ100

|

800

|

1.8*206*1.15m

|

||||

|

DGP-120B

|

600-700

|

55

|

Φ120

|

950

|

2.2*2.8*1.2m

|

||||

|

DGP-135B

|

750-800

|

75

|

φ133

|

950

|

2.2*2.8*1.2m

|

||||

|

DGP-160B

|

1000-1200

|

90

|

φ160

|

1200

|

2.3*3.0*1.2m

|

||||

|

DGP-200B

|

1800-2000

|

110

|

φ160

|

1450

|

2.4*3.2*1.4m

|

||||

|

NOTE

|

Screw can be added to increase output(For example, the screw output of DGP-80 3 section is 250-300kg/h, and the screw output of 4 section is 300-350kg/h)

|

|

|

|

|

||||

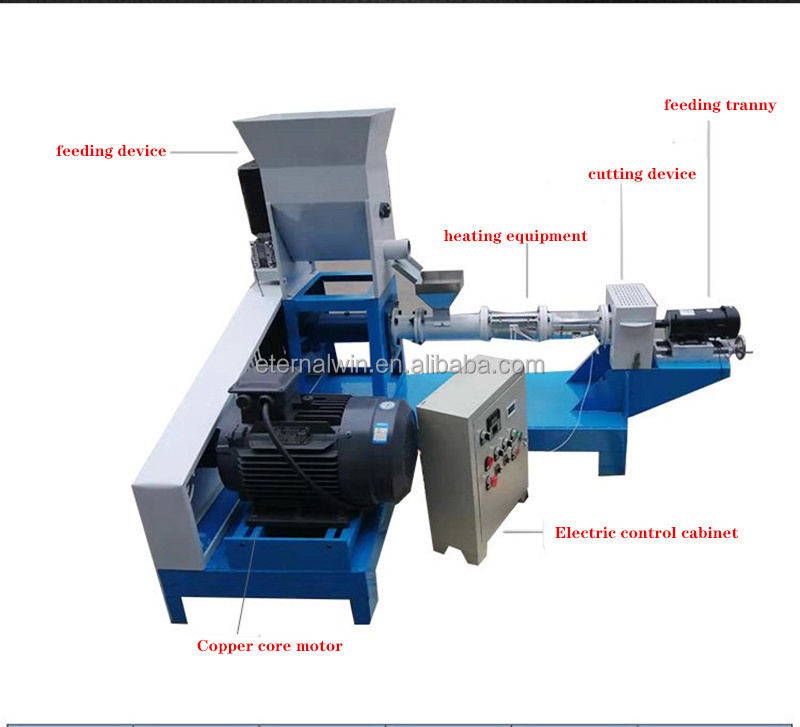

Product Details

Application

Main Features:

1. Advanced diced structure. Adopting knife shaft locating spring combined cutting form to cut the same length particle.

2. The screw adopts abrasion-resisting high temperature alloy steel, with characters of abrasion-resistance and long service.

3. There is unique pressurized die device inside to ensure the feed's production and quality.

4. Reasonable mainshaft bearing combination to ensure puffing machine's security and duration.

5. Main motor adopts high quality three-phase motor to ensure strong power.

6. The particle puffing feed produced by this machine can float in water 12 hours without dispersing. It is pollution-free and easy to be digested by fish.

7. The feed after produced through high temperature can kill escherichia coli, salmonella and other harmful bacterial , ensure the feed's hygiene.

8. It can save feed 8%-15%.

1. Advanced diced structure. Adopting knife shaft locating spring combined cutting form to cut the same length particle.

2. The screw adopts abrasion-resisting high temperature alloy steel, with characters of abrasion-resistance and long service.

3. There is unique pressurized die device inside to ensure the feed's production and quality.

4. Reasonable mainshaft bearing combination to ensure puffing machine's security and duration.

5. Main motor adopts high quality three-phase motor to ensure strong power.

6. The particle puffing feed produced by this machine can float in water 12 hours without dispersing. It is pollution-free and easy to be digested by fish.

7. The feed after produced through high temperature can kill escherichia coli, salmonella and other harmful bacterial , ensure the feed's hygiene.

8. It can save feed 8%-15%.

Hot Searches