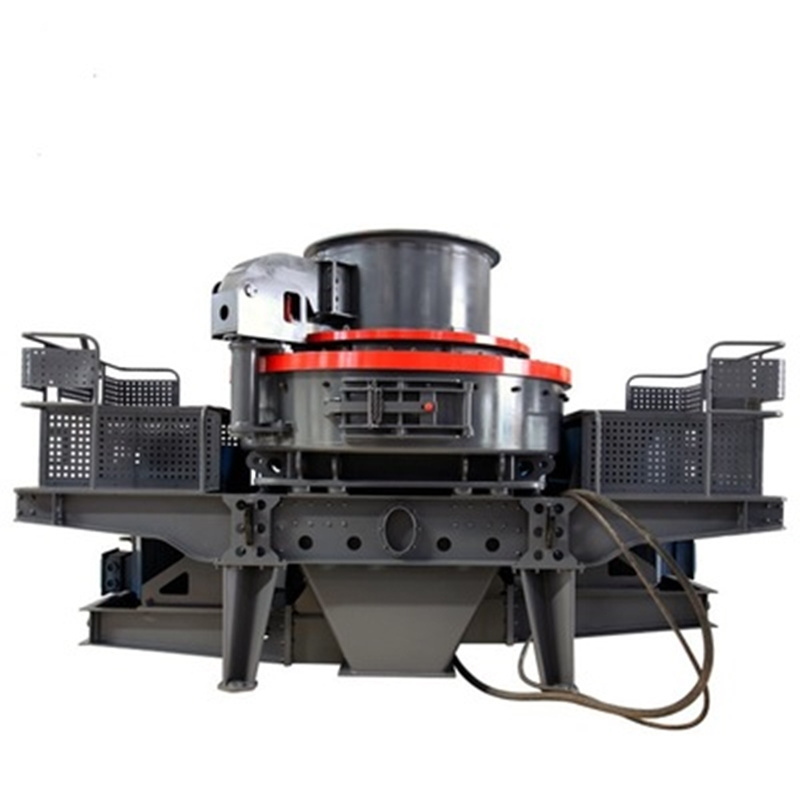

1.VSI

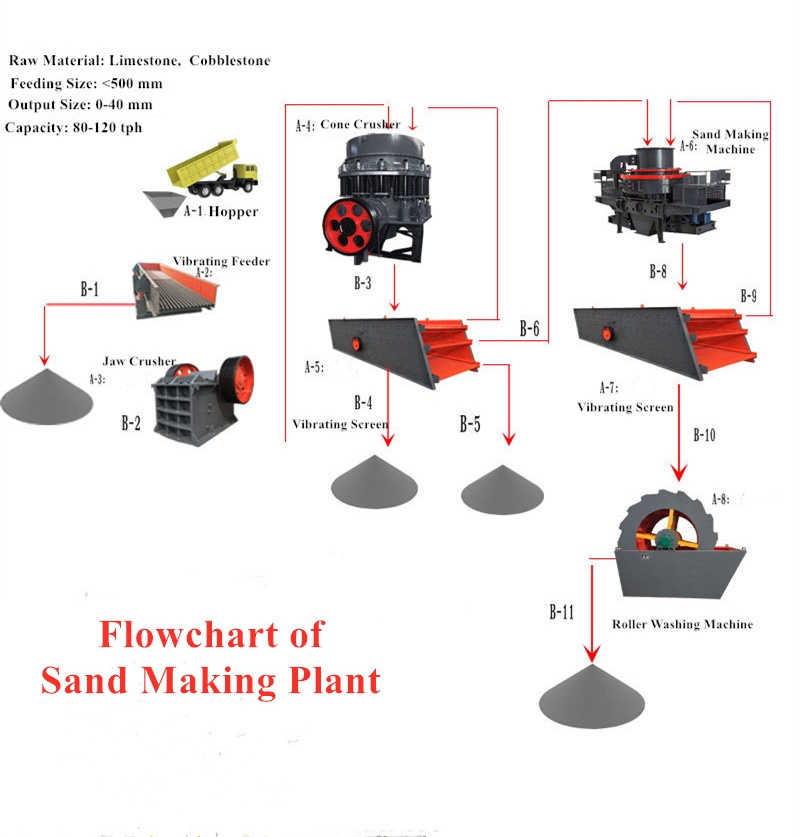

sand making plant

materials fall into the crusher and are divided into two parts.

2.One part goes into the high-speed-running impeller of the machine, and the other part goes around the impeller.

3.The two parts materials bump and crush fast during the effect of centrifugal force.

4.Then the materials run like swirl, bump and rub to each other again and again.

5.The finished products go out from the bottom of the machine, and users can get the requested products size after screening by vibrating screen.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

110-520 KW

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

6000 kg

-

Keyword:

-

Sand crusher machine

-

After-sales Service Provided:

-

Overseas service center available

-

Color:

-

Customizable

-

After-sale service:

-

Timely Solutions

-

Max feeding size:

-

50(mm)

-

Quality:

-

High-level

-

Function:

-

To make sands

-

Factory visit:

-

Warmly Welcomed

-

Spare parts supply:

-

Lifelong Provide

-

Power Source:

-

50Hz

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongke

-

Voltage:

-

380V/50HZ

-

Power:

-

110-520 KW

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

6000 kg

-

Keyword:

-

Sand crusher machine

-

After-sales Service Provided:

-

Overseas service center available

-

Color:

-

Customizable

-

After-sale service:

-

Timely Solutions

-

Max feeding size:

-

50(mm)

-

Quality:

-

High-level

-

Function:

-

To make sands

-

Factory visit:

-

Warmly Welcomed

-

Spare parts supply:

-

Lifelong Provide

-

Power Source:

-

50Hz

Quarry Granite Quartz Sand Making Machine Vsi Limestone Sand Crusher Machine Sand Making Plant Supplier

Product Description

Application Range of VSI sand making machine

1.VSI s and making plant can be used in Pebble,rock( the limestone, granite, basalt, aluminum, andesite, etc.), ore tailings,attle artificial sand production.

2.VSI sand making plant can be used in Building aggregate, highway, cushion, asphalt concrete and cement aggregate production.

3.VSI sand making plant and stone reshaping production in water conservancy and hydropower engineering

field,highway,railway,bridge,passenger line,airport runway,municipal engineering and high-rise buildings.

4.VSI sand making plant with high abrasive materials resistance and secondary disassembly, desulphuration of thermal power and metallurgy, slag and construction waste.

5.VSI sand making plant can be used in the production of glass,quartz sand and other high purity material.

1.VSI s and making plant can be used in Pebble,rock( the limestone, granite, basalt, aluminum, andesite, etc.), ore tailings,attle artificial sand production.

2.VSI sand making plant can be used in Building aggregate, highway, cushion, asphalt concrete and cement aggregate production.

3.VSI sand making plant and stone reshaping production in water conservancy and hydropower engineering

field,highway,railway,bridge,passenger line,airport runway,municipal engineering and high-rise buildings.

4.VSI sand making plant with high abrasive materials resistance and secondary disassembly, desulphuration of thermal power and metallurgy, slag and construction waste.

5.VSI sand making plant can be used in the production of glass,quartz sand and other high purity material.

|

Product Name

|

Sand Making Plant

|

|

Suitable for

|

Pebble,rock( the limestone, granite, basalt, aluminum, andesite,etc.)

|

|

Color

|

Customizable

|

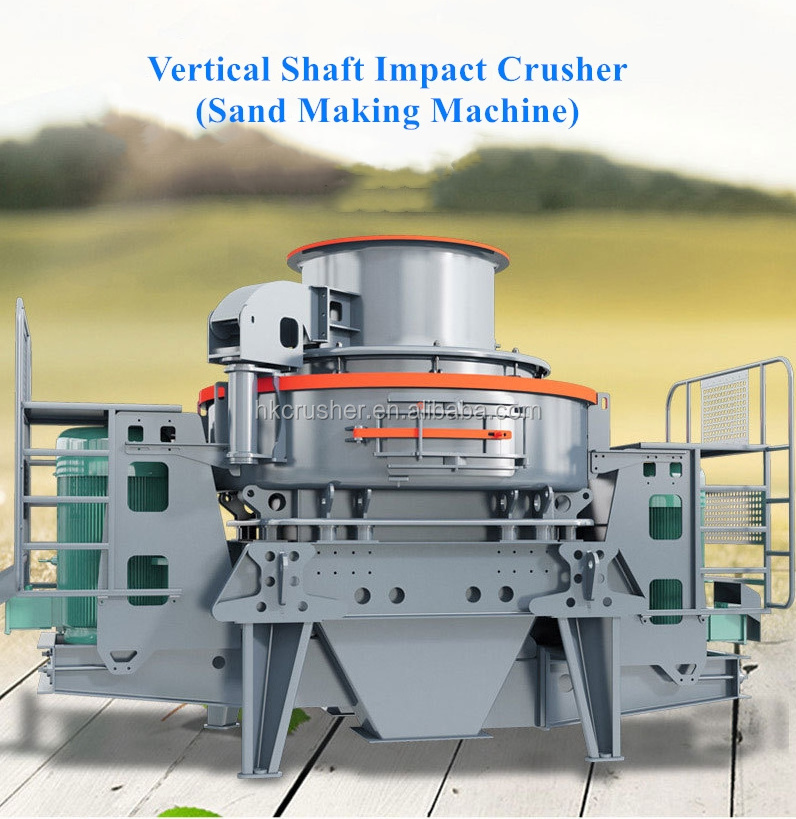

Working Prin

ciple

1.VSI

sand making plant

with Large handling capacity and High output;60-600t/h, the output of VSI has been stably increased 30%, comparing with the traditional equipment under the same motor power.

2.VSI sand making plant in Low wearing parts cost;Perfect impact angle design of the crushing cavity, less friction against the wearing parts. The operation cost reduces 40%.

3.VSI sand making plant with Perfect product shape. It fits especially man-made sand and stone reshaping.

4.VSI sand making plan t Hydraulic devices are maintained easily;Hydraulic door-opened device make the repair in the crushing cavity easily .Shorten downtime and save effort.

5.The vertical shaft impact crusher Automatic test, safe and reliable;Vibration display and warning device are set. The machine will be warned to stop working when abnormal phenomenon appears.

6.VSI sand making plan t Thinning oil lubricant and automatic maintenance;The original German thinning oil lubricant station,double-pump injection system guarantees the oil supply.

2.VSI sand making plant in Low wearing parts cost;Perfect impact angle design of the crushing cavity, less friction against the wearing parts. The operation cost reduces 40%.

3.VSI sand making plant with Perfect product shape. It fits especially man-made sand and stone reshaping.

4.VSI sand making plan t Hydraulic devices are maintained easily;Hydraulic door-opened device make the repair in the crushing cavity easily .Shorten downtime and save effort.

5.The vertical shaft impact crusher Automatic test, safe and reliable;Vibration display and warning device are set. The machine will be warned to stop working when abnormal phenomenon appears.

6.VSI sand making plan t Thinning oil lubricant and automatic maintenance;The original German thinning oil lubricant station,double-pump injection system guarantees the oil supply.

Detailed Images

Working Sites

Delivery and Packing

Size Information

|

Model

|

Max feeding size(mm)

|

Capacity(t/h)

|

Power(kw)

|

|

VSI-7611

|

35

|

60-180

|

110-150

|

|

VSI-8518

|

40

|

100-260

|

180-220

|

|

VSI-9526

|

45

|

150-380

|

264-320

|

|

VSI-1140

|

50

|

225-520

|

400-440

|

|

VSI-1145

|

50

|

250-600

|

440-520

|

|

5X7615

|

35

|

150-280

|

110-150

|

|

5X8522

|

40

|

240-380

|

180-220

|

|

5X9532

|

45

|

350-540

|

260-320

|

|

5X1145

|

50

|

500-640

|

400-440

|

|

6X1150

|

55

|

413-442

|

440-500

|

|

6X1263

|

60

|

545-583

|

600-630

|

Company Introduction

Henan Hongke Heavy Machinery Co., Ltd

. is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical

rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical

rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

Related Products

FAQ

1. What is the minimum order quantity?

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foundation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foundation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). feeding material

2). Feeding material MAX. Size (mm)

3). Final mesh size (mm)

4). Capacity (t/h)

Upon we got your message we shall give you our favorable offer in short time.

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). feeding material

2). Feeding material MAX. Size (mm)

3). Final mesh size (mm)

4). Capacity (t/h)

Upon we got your message we shall give you our favorable offer in short time.

Hot Searches