- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380v/420v

-

Dimension(L*W*H):

-

according to capacity

-

Marketing Type:

-

discount

-

Weight (KG):

-

87500 kg

-

Keywords:

-

Self insulation block machine

-

Keywords 2:

-

Self insulation block plant

-

Keywords 3:

-

Self insulating block machine

-

Product Name:

-

Self insulating block plant

-

Name:

-

Self Thermal Insulation block production line

-

Raw material:

-

sand, 425 cement, EPS polystyrene particles

-

Motor:

-

Siemens Motor

-

Autoclaved:

-

yes

-

electric control cabinet:

-

Siemens components

-

Local Service Location:

-

Russia/Kazakhstan/Uzbekistan/Egypt

Quick Details

-

Type:

-

Hollow Block Making Machine, Interlock Block Making Machine, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Fly Ash, cement, lime, sand

-

Production Capacity (Pieces/8 hours):

-

10,000~600,000 cbm per year

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380v/420v

-

Dimension(L*W*H):

-

according to capacity

-

Marketing Type:

-

discount

-

Weight (KG):

-

87500 kg

-

Keywords:

-

Self insulation block machine

-

Keywords 2:

-

Self insulation block plant

-

Keywords 3:

-

Self insulating block machine

-

Product Name:

-

Self insulating block plant

-

Name:

-

Self Thermal Insulation block production line

-

Raw material:

-

sand, 425 cement, EPS polystyrene particles

-

Motor:

-

Siemens Motor

-

Autoclaved:

-

yes

-

electric control cabinet:

-

Siemens components

-

Local Service Location:

-

Russia/Kazakhstan/Uzbekistan/Egypt

Self insulation block machine

EPS Production line

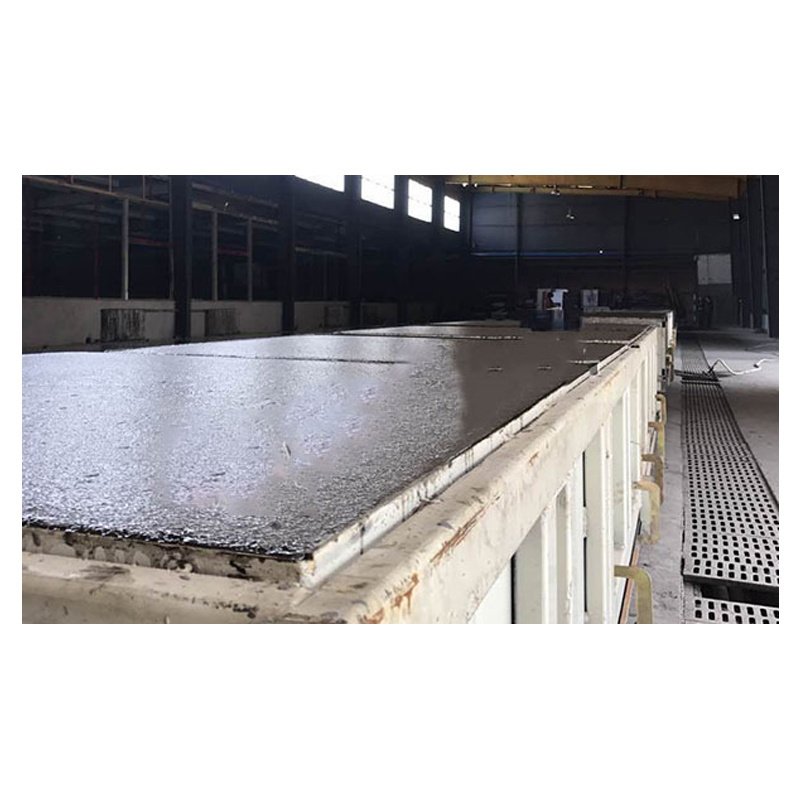

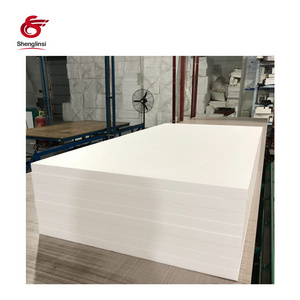

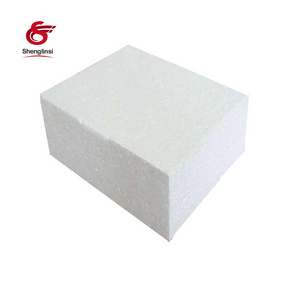

FTL Brand self insulation block contains polystyrene foam particles and foam concrete characteristics, its insulation and wall "two in one", FTL Brand self insulation block is composed of main block and polystyrene particles. FTL Brand self insulation block is made by mixing, pouring and cutting through cement foaming process. It has good thermal insulation performance, strong adhesion, good impermeability and crack resistance. The fully automatic production line of FTL Brand self insulation block equipment saves people and time, environmental protection and energy conservation. It can not only save energy and emission reduction for brick enterprises, but also recycle waste.

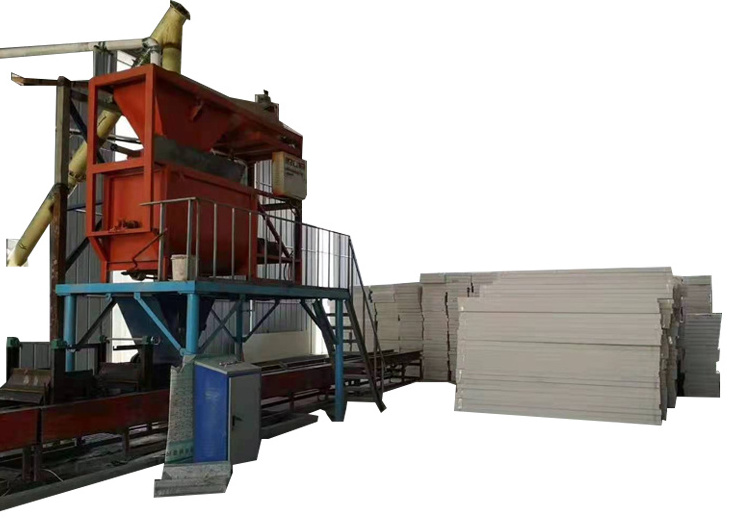

Main machine of FTL self insulation block production Line:

|

S crew conveyor |

F oaming machine |

Moulds |

C utting machine |

|

Powder measuring tank |

Mixing machine |

B ottom plate |

C utting hoist |

|

Cement measuring tank |

EPS feed system |

D emould hoist |

R otary hoist |

|

W ater storage tank |

Pouring machine |

PLC control system |

P acking machine |

Raw material of FTL self insulation block production Line

Self insulation block raw materials: sand, 425 cement, EPS polystyrene particles, foaming agent, latex powder (cellulose, powder).

Technical data of detachable integrated board

Main raw materials: quartz sand, 425 cement, extruded board, additives (rubber powder, cellulose, polypropylene fiber, etc.). Insulation nail, grid cloth;

Working Principle of FTL self insulation block production Line

Working principle of S elf I nsulation block equipment : self insulation block equipment starts from batching→ mixing → molding → demoulding → cutting → curing → inspection and deliver from factory . The whole process flow of the factory is simple and convenient, with large output and high return on investment. It is a new production equipment of environmental protection building materials. Common silicate Cement is the main cementitious material of FTL brand self insulation block , and which is add ed an appropriate amount of polystyrene particles, fibers and additives. The material has the advantages of energy saving and waste utilization, good thermal insulation performance and low cost. The production equipment of FTL Brand thermal insulation block is composed of polymer modified slurry and continuous and uniform wall hydatid cement thermal insulation board, which is mainly used to produce building fireproof exterior wall thermal insulation board, and the raw materials are cement and polymer particles. FTL Brand self insulation block is composed of main block and polystyrene particles. FTL Brand self insulation block is made by mixing, pouring and cutting through cement foaming process. It has good thermal insulation performance, strong adhesion, good impermeability and crack resistance.

The fully automatic production line of FTL Brand self-protection block equipment saves people and time, environmental protection and energy conservation. It can not only save energy and emission reduction for brick enterprises, but also recycle waste. FTL Brand self insulation block has self insulation, fire resistance, frost resistance, shrinkage resistance, crack resistance, low water absorption, sound insulation, fire resistance and light weight .

About us:

Customers' visiting: