- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3800*930*1890mm

-

Power (kW):

-

15

-

Weight (KG):

-

4800 kg

-

Product name:

-

Rubber Calender

-

After-sales Service Provided:

-

Repair Service

-

Material:

-

Metal

-

Feature:

-

Easy Operation

-

Gearbox:

-

Hardened Teeth Gearbox

-

Advantage:

-

High Precision

-

Color:

-

Customers' Demand

-

Roller type:

-

4 Rolls

-

Keywords:

-

Four Roller Rubber Calender

-

Application:

-

Put rubber on fabrics, to rubberize fabrics, or to make rubber sheet

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TOPLIT

-

Voltage:

-

380v, 415V, 420V, 440V

-

Dimension(L*W*H):

-

3800*930*1890mm

-

Power (kW):

-

15

-

Weight (KG):

-

4800 kg

-

Product name:

-

Rubber Calender

-

After-sales Service Provided:

-

Repair Service

-

Material:

-

Metal

-

Feature:

-

Easy Operation

-

Gearbox:

-

Hardened Teeth Gearbox

-

Advantage:

-

High Precision

-

Color:

-

Customers' Demand

-

Roller type:

-

4 Rolls

-

Keywords:

-

Four Roller Rubber Calender

-

Application:

-

Put rubber on fabrics, to rubberize fabrics, or to make rubber sheet

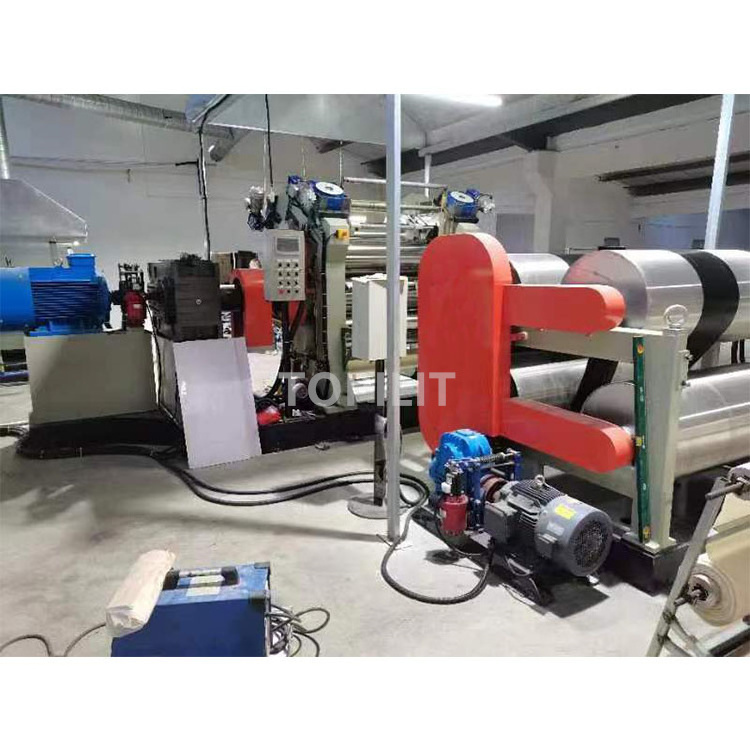

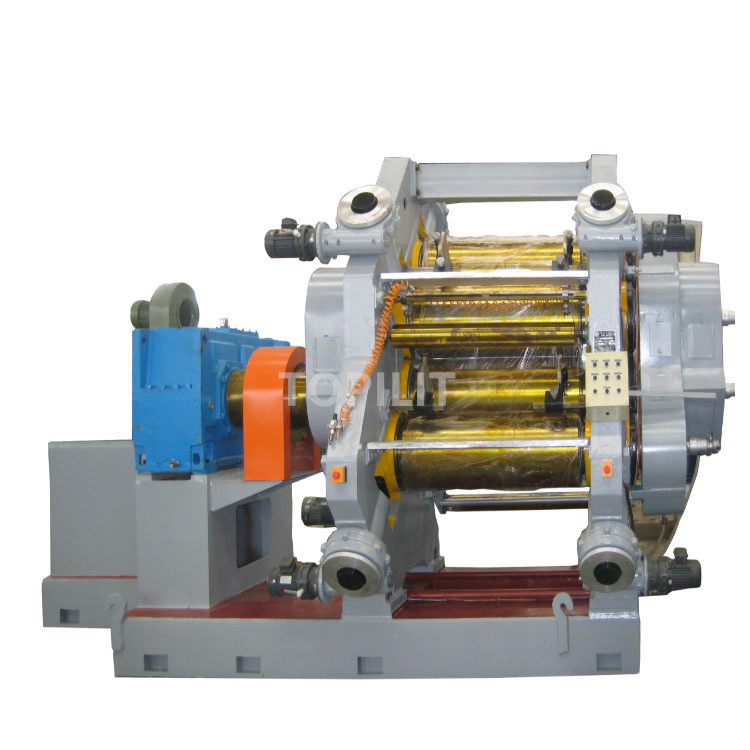

High Speed Wear-Resistant Calendering Sheet Rubber Machine 4 Rolls Rubber Calender For Fabric Coating

Equipment summary

Rubber calendering machine is mainly used for: Textile (cloth, canvas, etc.) of glue and eraser; steel cord adhesive; rubber compression and pressure type; cord attached to the fit of the isolation film and multilayer film.

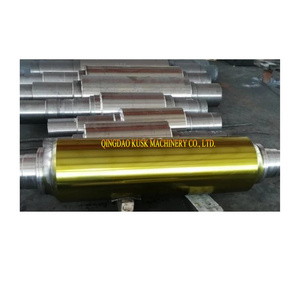

1.Rolls: chilled alloy cast iron rolls with worksurface highhardness 68~72hs, so it is wear-resistant and durable. The rolls are mirror finished & polished, duly grinding and are hollowed for cooling or heating.

2.Roll clearance adjusting unit: nip adjustment at two roller ends is done manually using two separate screws attached to the brass housing body. Roller space can be adjusted both by manual or electric mode.

3.Roll cooling: universal rotary joints with inner spray pipes with hoses and headers. piping is complete up to supply pipe terminal.

4.Journal bearing housing: heavy duty steel casting housing fitted with anti friction roller bearings.

5.Lubrication: full automatic grease lubrication pump for anti friction roller bearings fitted in dust sealed housing.

6.Stand frame & apron: heavy duty steel casting.

7.Gearbox: hard-tooth reduction gearbox, GUOMAO brand.

8.Base frame: common base frame heavy duty, steel channel and ms plate fabricated accurately machined on which whole machine with gearbox and motor are fitted.

9.Electric panel: star delta electric operating panel with auto reversing, voltmeter, ampere, overload protection relay, 3 phase indicator and emergency stop switch.

While using, the steem, cooling water and heat-conducting oil can be passed into the roller's cavity, so that the working temparature can be adjusted in order to meet the technological requirement.

Structure description:

1. Body

1) Frame: Welded and formed, annealed, fully processed by precision machine tools, strong rigidity, no deformation, smooth sliding surface, flat and wear-resistant.

2) Base: Welded base, machined after annealing treatment, with good rigidity and no deformation.

2. Roller and bearing set

1) Roller structure: hollow smooth roller.

2) Material: alloy chilled cast iron LTH-H.

3) Hardness: 68-72HSD.

4) Chill layer: 10-20mm.

5) Main bearing: four-row cylindrical roller bearing

6) Bearing seat: cast by tempering, with lubricating oil hole.

7) Roll temperature adjustment adopts high-quality rotary joint and stainless steel metal hose.

3. Pitch adjustment device

1) Adjusting speed: 1.59-40m/min.

2) Drive motor power: 15-220KW.

3) The gap adjustment is used for 1#, 2#, 4# rollers. Both ends can be adjusted simultaneously or individually.

4. Rubber stopper

Adjust the distance: 800-1300mm, manual adjustment.

5. The width of the rubber cutter is adjusted manually, and the clutch between the rubber cutter and the roller is driven by the air cylinder.

6. Reducer

1) Type: One motor input, one shaft output.

2) Lubrication device: oil bath lubrication.

3) Input coupling: flexible coupling.

7. Rod pin coupling

The output shaft of the reducer is connected with the main machine roller by a rod-pin coupling, which makes the operation smooth and flexible, no noise, and simple maintenance.

8. Lubrication system

1) Bearing lubrication: This system contains an oil tank, including flow adjustment, oil temperature gauge, cooler, filter, etc., to control the flow and reduce the lubricating oil temperature and ensure the cleanliness of the lubricating oil.

2) Thin oil lubrication pipeline.

1. Body

1) Frame: Welded and formed, annealed, fully processed by precision machine tools, strong rigidity, no deformation, smooth sliding surface, flat and wear-resistant.

2) Base: Welded base, machined after annealing treatment, with good rigidity and no deformation.

2. Roller and bearing set

1) Roller structure: hollow smooth roller.

2) Material: alloy chilled cast iron LTH-H.

3) Hardness: 68-72HSD.

4) Chill layer: 10-20mm.

5) Main bearing: four-row cylindrical roller bearing

6) Bearing seat: cast by tempering, with lubricating oil hole.

7) Roll temperature adjustment adopts high-quality rotary joint and stainless steel metal hose.

3. Pitch adjustment device

1) Adjusting speed: 1.59-40m/min.

2) Drive motor power: 15-220KW.

3) The gap adjustment is used for 1#, 2#, 4# rollers. Both ends can be adjusted simultaneously or individually.

4. Rubber stopper

Adjust the distance: 800-1300mm, manual adjustment.

5. The width of the rubber cutter is adjusted manually, and the clutch between the rubber cutter and the roller is driven by the air cylinder.

6. Reducer

1) Type: One motor input, one shaft output.

2) Lubrication device: oil bath lubrication.

3) Input coupling: flexible coupling.

7. Rod pin coupling

The output shaft of the reducer is connected with the main machine roller by a rod-pin coupling, which makes the operation smooth and flexible, no noise, and simple maintenance.

8. Lubrication system

1) Bearing lubrication: This system contains an oil tank, including flow adjustment, oil temperature gauge, cooler, filter, etc., to control the flow and reduce the lubricating oil temperature and ensure the cleanliness of the lubricating oil.

2) Thin oil lubrication pipeline.

|

Model

|

XY-4I(Γ)

230*630 |

XY-4I(Γ)

252*720 |

XY-4I(Γ)

300*900 |

XY-4I(Γ/S)

360*1120 |

|

Roll diameter(mm)

|

230

|

252

|

300

|

360

|

|

Working length of rolls(mm)

|

630

|

720

|

900

|

1120

|

|

linear speed of middle roll(m/min)

|

2.1-

21 |

1.59-15.9

|

1.8-18

|

2-20.1

|

|

Speed ratio

|

1:1:1:1

|

1:1:1:1

|

1:1:1:1

|

0.733:1:1:0.733

|

|

Adjusting nip range (mm)

|

0-10

|

10

|

10

|

0-10

|

|

Min. calendaring product thickness(mm)

|

0.2

|

0.2

|

0.2

|

0.2

|

|

Calendaring product width(mm)

|

500

|

580

|

700

|

920

|

|

Driving motor power(kw)

|

15

|

22

|

45

|

55

|

|

Overall size(L*W*H) mm

|

3800*930*1890

|

2950*990*1645

|

4400*1650*2200

|

3330*1940*2350

|

|

weight(ton)

|

4.8

|

5

|

12

|

16

|

|

XY-4I(Γ)

400*1200 |

XY-4I(Γ)

450*1400 |

XY-4I(Γ/S)

550*1500 |

XY-4I(Γ/S)

610*1730 |

XY-4I(Γ/S)

700*1850 |

XY-4I(Γ/S)

710*2130 |

|

400

|

450

|

550

|

610

|

700

|

710

|

|

1200

|

1400

|

1500

|

1730

|

1850

|

2130

|

|

3-36.3

|

2.5-25

|

3-30

|

8-50

|

4-40

|

3-30

|

|

1:1.383:1.383:1

|

1:1.5:1.5:1

|

1:1.5:1.5:1

|

1:1.4:1.4:1

1:1.4:1.4:1.4 |

0.5-1 adjustable

|

1:1.5:1.5:1

|

|

0-10

|

0-10

|

0-10

|

0-20

|

0-30

|

0-20

|

|

0.2

|

0.2

|

0.2

|

0.15

|

0.2

|

0.15

|

|

1000

|

1220

|

1300

|

1500

|

1600

|

1900

|

|

75

|

110

|

160

|

185

|

90kw * 2

110kw*2 |

220

|

|

6400*1620*2490

|

6500*1970*2740

|

7550*2400*3400

|

6580*2460*2920

|

9950*3600*4870

|

7010*4150*3730

|

|

20

|

23

|

45

|

50

|

110

|

100

|

Qingdao TOPLIT Industry Co.,Ltd

is a professional provider of rubber machine.

Our products mainly include kneader, banbury mixer, mixing mill, refiner, calender, extruder, batch off cooler, plate curing press, microwave curing machine, cracker mill, skiving machine, extruder, tire reclaimed rubber machines, butyl reclaimed rubber machines, EPDM reclaimed rubber machines, rubber powder machines, and so on.

We enjoy good reputation with reasonable price, best quality and good delivery. And we sincerely welcome clients from home and abroad to establish long and steady business relations and develop domestic and international market jointly on the base of equality and mutual benefit.

Q1.WHO ARE YOU?

A: We are Professional Provider of Rubber Machine in China for many years.

Q2.ARE YOU AN COMPREHENSIVE SUPPLIER FOR RUBBER&PLASTIC MACHINE?

A: Yes, we can provide the complete solution line to customer according to customer's requirement.

Q3. HOW ABOUT THE QUALITY CONTROL IN YOUR FACTORY?

A: We has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP.

Q4. WHAT ABOUT THE AFTER-SERVICE? WILL YOU SEND YOUR ENGINEER TO MY COUNTRY TO HELP COMMISSION AND INSTALL THE MACHINE?

A: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers.

Q5. WHAT IS THE DELIVERY TIME OF THE MACHINE?

A: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within10-60 days.

Q6. WHAT IS THE WARRANTY OF THE MACHINE?

A: The whole machine's warranty period is 12 months and spare parts will be depended.

Hot Searches