- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

xufang

-

Model Number:

-

6(61788-97-4)(25)

-

Type:

-

epoxy resin

-

Storage:

-

12 months

-

Purity:

-

99%

-

Condition:

-

100% Tested and working

-

Packing:

-

20kg/metal barrel

-

Product name:

-

Epoxy resin

-

Feature:

-

Non VOC,Non Odour,100% Solid, Solvent Free

-

MOQ:

-

1 Ton

-

Sample:

-

Available

-

Appearance:

-

Clear liquid

-

Molecular weight:

-

375.864

Quick Details

-

CAS No.:

-

61788-97-4

-

Other Names:

-

epoxy resin

-

MF:

-

(C11H12O3)n

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

xufang

-

Model Number:

-

6(61788-97-4)(25)

-

Type:

-

epoxy resin

-

Storage:

-

12 months

-

Purity:

-

99%

-

Condition:

-

100% Tested and working

-

Packing:

-

20kg/metal barrel

-

Product name:

-

Epoxy resin

-

Feature:

-

Non VOC,Non Odour,100% Solid, Solvent Free

-

MOQ:

-

1 Ton

-

Sample:

-

Available

-

Appearance:

-

Clear liquid

-

Molecular weight:

-

375.864

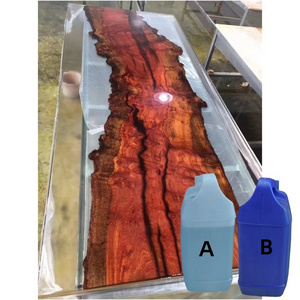

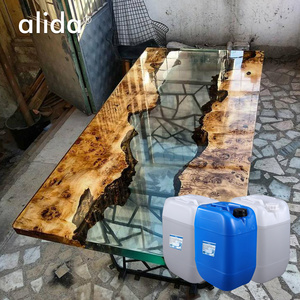

Best Selling

Product Description

Epoxy resins are a class of thermosetting polymers made from monomers that contain at least two epoxide groups. They provide strong adhesion, chemical resistance and other specialized properties. Due to these qualities, epoxy resins are used in a variety of consumer and industrial products.

“Uncured” epoxy resins refer to the polymer containing multiple epoxy groups produced from a reactive process. “Cured” epoxy resins (also known as epoxies) have undergone a chemical reaction which “cross-linked” polymer chains. This process uses a variety curing agents, also known as hardeners. The term “epoxy resins” can refer to both the cured end product and the uncured resin.

Epoxy resins can be solid, liquid or dissolved in a solvent. At room temperature, these resins are generally solid but revert to a viscous liquid (one with a thick, sticky consistency) when heated. When cross-linked, epoxy resins are hard, abrasion and chemically resistant, dimensionally stable, with strong electrical and insulation properties.

“Uncured” epoxy resins refer to the polymer containing multiple epoxy groups produced from a reactive process. “Cured” epoxy resins (also known as epoxies) have undergone a chemical reaction which “cross-linked” polymer chains. This process uses a variety curing agents, also known as hardeners. The term “epoxy resins” can refer to both the cured end product and the uncured resin.

Epoxy resins can be solid, liquid or dissolved in a solvent. At room temperature, these resins are generally solid but revert to a viscous liquid (one with a thick, sticky consistency) when heated. When cross-linked, epoxy resins are hard, abrasion and chemically resistant, dimensionally stable, with strong electrical and insulation properties.

1. Various forms.:

Various resin, curing agent, and modifier systems can almost meet the requirements of various applications for form, ranging from extremely low viscosity to high melting point solids.

2. Convenient solidification:

By using various curing agents, the epoxy resin system can almost cure within the temperature range of 0-180 ℃.

3. Strong adhesion:

The presence of inherent polar hydroxyl and ether bonds in the molecular chain of epoxy resin gives it high adhesion to various substances. The shrinkage of epoxy resin during curing is low, resulting in low internal stress, which also helps to improve adhesion strength.

4. Low contractility:

The reaction between epoxy resin and the curing agent used is carried out through direct addition reaction or ring opening polymerization reaction of epoxy groups in resin molecules, without the release of water or other volatile by-products. Compared with unsaturated polyester resin and phenolic resin, they exhibit very low shrinkage (less than 2%) during the curing process.

5. Mechanical properties:

The cured epoxy resin system exhibits excellent mechanical properties.

6. Electrical performance:

The cured epoxy resin system is an excellent insulation material with high dielectric properties, surface leakage resistance, and arc resistance.

7. Chemical stability:

Usually, cured epoxy resin systems have excellent alkali resistance, acid resistance, and solvent resistance. Like other properties of cured epoxy systems, chemical stability also depends on the selected resin and curing agent. Proper selection of epoxy resin and curing agent can give it special chemical stability properties.

8. Dimensional stability:

The combination of many of the above properties gives the epoxy resin system outstanding dimensional stability and durability.

9. Resistant to mold:

The cured epoxy resin system is resistant to most fungi and can be used under harsh tropical conditions.

The excellent physical, mechanical, and electrical insulation properties, adhesive properties with various materials, as well as the flexibility of its usage process of epoxy resin are not possessed by other thermosetting plastics. Therefore, it can be made into coatings, composite materials, casting materials, adhesives, molding materials, and injection molding materials, and is widely used in various fields of the national economy.

1. Application of coatings:

Epoxy resin accounts for a large proportion of applications in coatings, and it can be made into various varieties with unique characteristics and different uses.

2. Adhesive application:

In addition to poor adhesion to non-polar plastics such as polyolefins, epoxy resin is also suitable for various metal materials such as aluminum, iron, and copper; Non metallic materials such as glass, wood, concrete, etc; And thermosetting plastics such as phenolic, amino, unsaturated polyester, etc. have excellent adhesive properties, hence they are called versatile adhesives. Epoxy adhesive is an important type of structural adhesive.

3. Electronic appliances:

Due to the unique advantages of epoxy resin such as high insulation performance, strong structural strength, and good sealing performance, it has been widely used in the insulation and packaging of high and low voltage electrical appliances, motors, and electronic components, and has developed rapidly.

In addition, epoxy insulation coatings, insulation adhesives, and electrical adhesives are also widely used.

Paints and Coatings

Adhesive

Flooring

Aerospace

Specification

Epoxy resin and epoxy resin adhesives themselves are non-toxic, but due to the addition of solvents and other toxic substances during the preparation process, many epoxy resins are "toxic." The domestic epoxy resin industry is maintaining the "non-toxic" nature of epoxy resins through water-based modification and avoiding additives.

Epoxy resin is generally used together with additives to obtain application value. Additives can be selected according to different uses, and commonly used additives include the following categories: (1) curing agents; (2) Modifying agent; (3) Filler; (4) Diluent; (5) Other.

Curing agent is an essential additive, whether used as an adhesive, coating, or pouring material, it is necessary to add curing agent, otherwise the epoxy resin cannot cure. Due to different performance requirements, there are also different requirements for additives such as epoxy resin, curing agents, modifiers, fillers, and diluents.

|

Product Name

|

Epoxy Equivalent

(g/eq) |

Dissolved Viscosity(25℃)*

|

I.C.I Viscosity

(cps/150℃)** |

Softening Point(℃)

|

Hue

(G) |

Description

|

|

E44

|

210~230

|

-

|

20000~24000

|

14~23

|

1.0max

|

Used for pipeline anti-corrosion coating

|

|

E51

|

210~244

|

-

|

10000~16000

|

15~23

|

1.0max

|

Used for pipeline anti-corrosion coating

|

|

NPES-901

|

450~500

|

D~F

|

-

|

64~74

|

1.0max

|

Vinyl ester, CFRP,

Used for coatings and adhesives |

|

NPES-901H

|

580~610

|

I~L

|

-

|

80~85

|

1.0max

|

Vinyl ester, CFRP,

Used for coatings |

|

NPES-902

|

600~650

|

I~M

|

-

|

82~92

|

1.0max

|

Used for coatings

|

|

NPES-902H

|

680~710

|

K~P

|

2000~4500

|

90~95

|

1.0max

|

Used for coatings

|

|

NPES-903

|

700~750

|

N~R

|

3000~5000

|

90~98

|

1.0max

|

Used for powder coatings

|

|

NPES-903H

|

740~780

|

P~S

|

3500~6000

|

92~100

|

1.0max

|

Used for powder coatings

|

|

NPES-903K

|

670~700

|

K~P

|

2000~4000

|

88~95

|

1.0max

|

Used for powder coatings

|

|

NPES-904

|

780~850

|

S~W

|

4500~8000

|

96~107

|

1.0max

|

Used for powder coatings and epoxy polyester,also can be used for electronic sealing adhesive and other materials

|

|

NPES-904H

|

840~900

|

V~X

|

6000~9000

|

100~112

|

1.0max

|

Used for powder coatings and epoxy polyester

|

|

NPES-904F

|

810~860

|

P~U

|

6500~9500

|

96~107

|

1.0max

|

Pre added catalyst for synthesizing epoxy polyester

|

|

NPES-905L

|

900~930

|

-

|

9500~23000

|

95~110

|

1.0max

|

Used for pipeline powder coating

|

|

NPES-906H

|

1250~1400

|

-

|

-

|

105~125

|

1.0max

|

Used for steel bar powder coating

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches