- Product Details

- {{item.text}}

Quick Details

-

Specification:

-

60mm

-

Application:

-

Volume/Lighting Control

-

Series:

-

MSV02

-

Features:

-

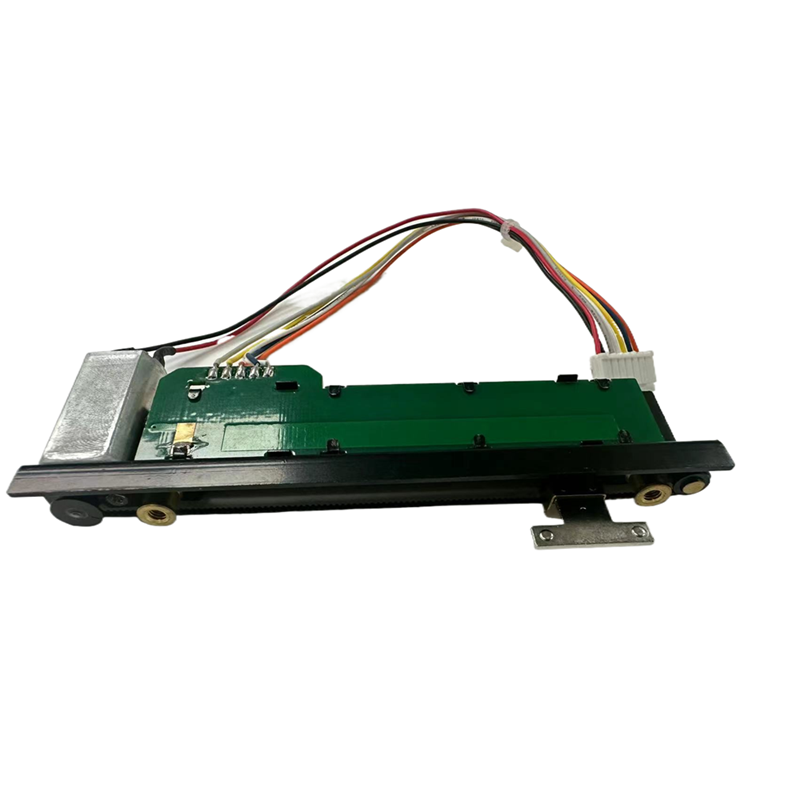

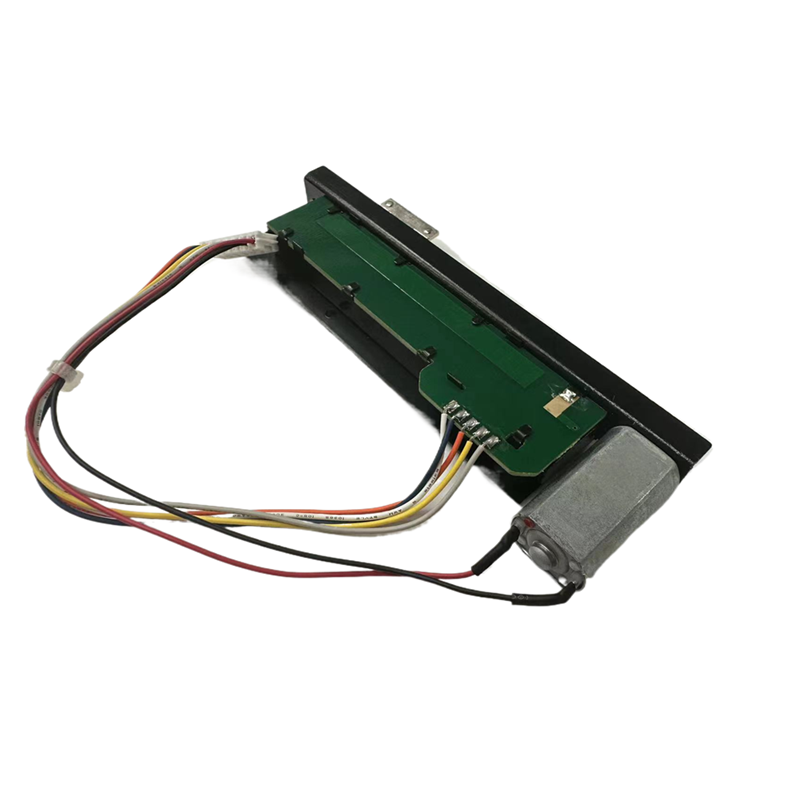

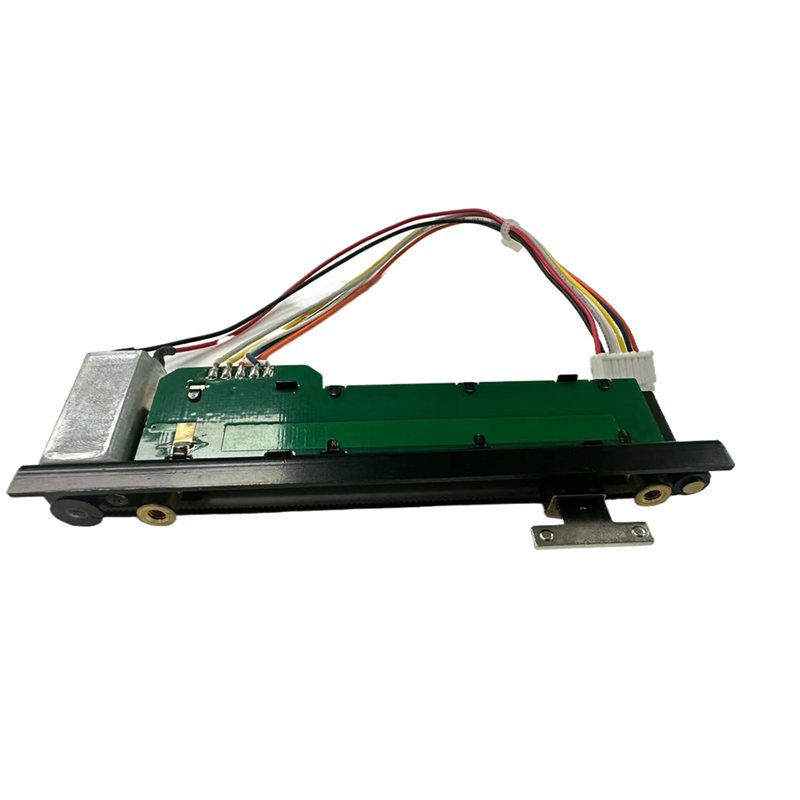

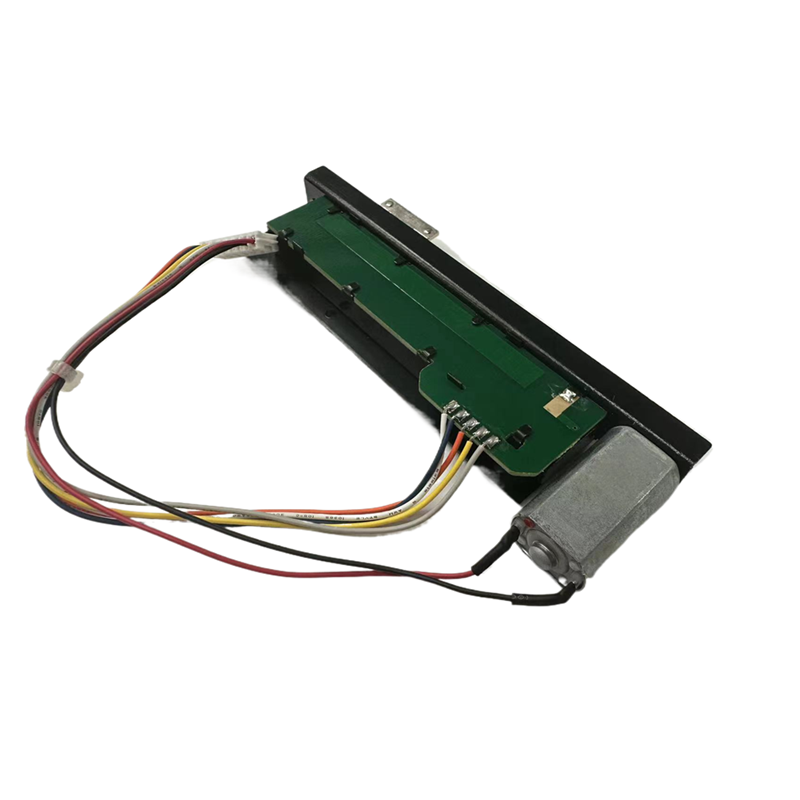

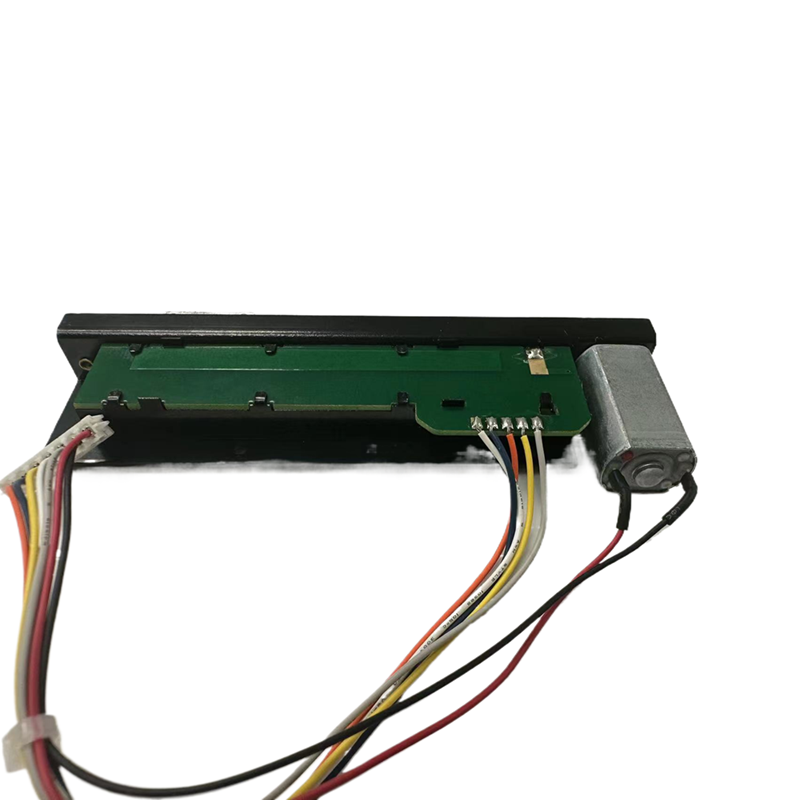

Slide Motorized Potentiometer

-

Description:

-

Motorized Potentiometer

-

Manufacturing Date Code:

-

2024

-

Resistance:

-

5K/10k/100k

-

Resistance Tolerance:

-

±10%-20%

-

Life:

-

1 Millions

-

Travel Length:

-

60mm

-

Noise:

-

100mv

-

Linearity:

-

±2%-2.5%

-

Working Temperature:

-

-10℃ to 70℃

-

Mechanical Travel:

-

60mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cooka

-

Model Number:

-

MSV02

-

Specification:

-

60mm

-

Application:

-

Volume/Lighting Control

-

Series:

-

MSV02

-

Features:

-

Slide Motorized Potentiometer

-

Description:

-

Motorized Potentiometer

-

Manufacturing Date Code:

-

2024

-

Resistance:

-

5K/10k/100k

-

Resistance Tolerance:

-

±10%-20%

-

Life:

-

1 Millions

-

Travel Length:

-

60mm

-

Noise:

-

100mv

-

Linearity:

-

±2%-2.5%

-

Working Temperature:

-

-10℃ to 70℃

-

Mechanical Travel:

-

60mm

Product Description

Why Cooka?

Cooka-innovating the world of high-end sensors, digital encoders, automotive electronics, integrated circuits and other electronic

products .Manufactured according to ISO-9001 standards, using silver paste for better conductivity and groundbreaking carbon film

technologies, our products are not only higher quality but safer and last longer.

Company Advantages

1.Excellent product life ability, current development is more than 20 million cycles life

Through 5 years of technological research and development, Cooka technology has continuously improved and developed in the field of carbon thick film. So far, the life of the product has been increased by more than 30 million cycles life. Cooka thick film technology has enabled the company's products to reach the world class level. At the same time, Cooka still insists on continuous innovation, improving service and making better products.

2.Super electronic contact performance. Signal noise as low as 20mv.

Cooka, based on the innovation application of electronic materials, alloy materials and structures, greatly improves the physical contact performance of products, thus enhancing the contact reliability and electrical seismic performance.

3.The application of ZERO-WEAR technology gives our produts super precision capabilities.

Through a large number of electronic materials, Cooka discovered several key materials. The application of these key materials can effectively reduce the wear of the electric contactor on the resistance body during the use of the product and reduce the variation of impedance. Cooka's application of this technology to high-end sensors effectively ensures the accuracy retention capability of the product during use.

4.New Carbon film technology application, excellent anti-interference.

Carbon based resistance sensor is different from Hall sensor, which is a physical structure product and has the ability to be free from magnetic interference.

Cooka-innovating the world of high-end sensors, digital encoders, automotive electronics, integrated circuits and other electronic

products .Manufactured according to ISO-9001 standards, using silver paste for better conductivity and groundbreaking carbon film

technologies, our products are not only higher quality but safer and last longer.

Company Advantages

1.Excellent product life ability, current development is more than 20 million cycles life

Through 5 years of technological research and development, Cooka technology has continuously improved and developed in the field of carbon thick film. So far, the life of the product has been increased by more than 30 million cycles life. Cooka thick film technology has enabled the company's products to reach the world class level. At the same time, Cooka still insists on continuous innovation, improving service and making better products.

2.Super electronic contact performance. Signal noise as low as 20mv.

Cooka, based on the innovation application of electronic materials, alloy materials and structures, greatly improves the physical contact performance of products, thus enhancing the contact reliability and electrical seismic performance.

3.The application of ZERO-WEAR technology gives our produts super precision capabilities.

Through a large number of electronic materials, Cooka discovered several key materials. The application of these key materials can effectively reduce the wear of the electric contactor on the resistance body during the use of the product and reduce the variation of impedance. Cooka's application of this technology to high-end sensors effectively ensures the accuracy retention capability of the product during use.

4.New Carbon film technology application, excellent anti-interference.

Carbon based resistance sensor is different from Hall sensor, which is a physical structure product and has the ability to be free from magnetic interference.

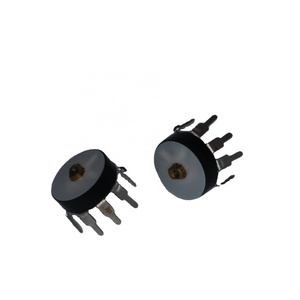

Technology:

Carbon Composition

Tolerance:

±20%

Adjustment Type:

Slide

Built in Switch:

Not Applicable

Temperature Coefficient

:±500ppm/°C

Rotation:

Not Applicable

Resistive Material:

Carbon

Termination style:

Wire Leads

Actuator Type:

Wire Leads

Actuator Diameter:

Not Applicable

Bushing Thread:

Wire Leads

shaft size:

Not Applicable

Number of Turns:

Not Applicable

Description:

MSV02

Max. operating voltage:

30

Resistance Tolerance:

20%

Actuator Length:

None

Diameter:

None

Operating Temperature:

-10℃~+70℃

Termination:

Terminal Pin

Mounting Type:

Screw Lock

Resistance:

5K

Power (Watts):

0.25

Type:

Motorized Slide Potentiometer

Length:

None

Rated Power:

0.25watt

Specification

|

Resistance

|

5K±20%/10K±20%

|

|

Power Rating

|

0.25 Watt @ 40℃

|

|

Linearity

|

±2%

|

|

Noise

|

200mv

|

|

TCR

|

±500ppm

|

|

Hi-Pot

|

500VAC 1 minutes

|

|

Life Cycles

|

1 Million

|

|

Electrical Travel

|

58±2mm

|

|

Rotary Torque

|

30g.cm Max.

|

|

Operating Temp.

|

-10℃~70℃

|

|

Mechanical Travel

|

60mm

|

Drying Workshop

Thick Film Screen Workshop

Quality Tester

Hot Searches