- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

YT-LDC-1000

-

Power:

-

230

-

Weight (KG):

-

16500 kg

-

Name:

-

Lithium Battery Recycling Plant

-

Raw material:

-

Lithium Battery Scrap

-

Final product:

-

Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix P

-

Certification:

-

CE

-

Color:

-

Customized Color

-

Appliactions:

-

All Kinds Of Lithium Batteries

-

After-sales Service Provided:

-

Online Support

-

MOQ:

-

1 Set

-

Separation methods:

-

Physical Method Separating Method

-

Capacity:

-

800-1000KG/H

Quick Details

-

Production Capacity:

-

800-1000KG/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou YATAI

-

Model Number:

-

YT-LDC-1000

-

Power:

-

230

-

Weight (KG):

-

16500 kg

-

Name:

-

Lithium Battery Recycling Plant

-

Raw material:

-

Lithium Battery Scrap

-

Final product:

-

Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix P

-

Certification:

-

CE

-

Color:

-

Customized Color

-

Appliactions:

-

All Kinds Of Lithium Batteries

-

After-sales Service Provided:

-

Online Support

-

MOQ:

-

1 Set

-

Separation methods:

-

Physical Method Separating Method

-

Capacity:

-

800-1000KG/H

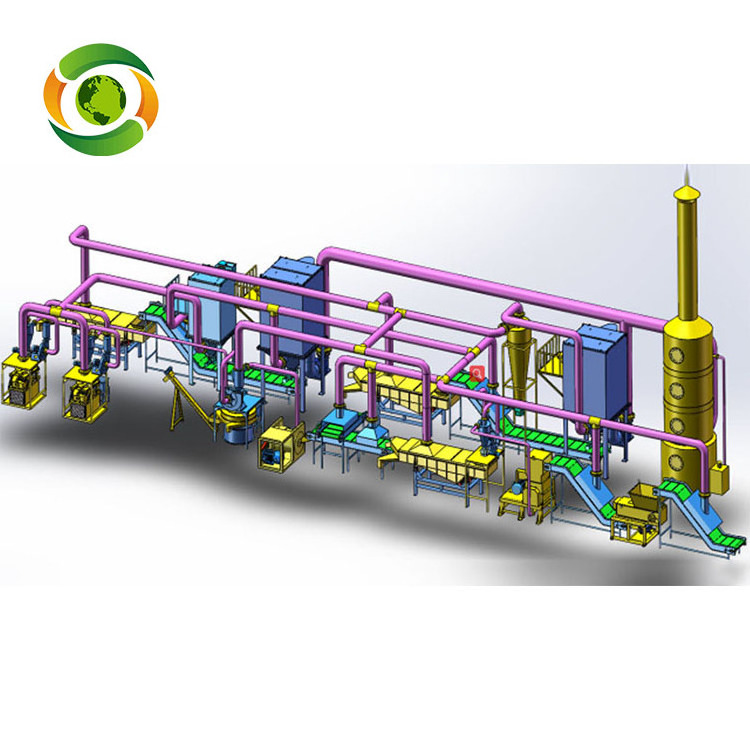

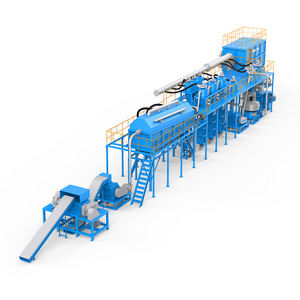

LITHIUM BATTERY RECYCLING PLANT

BACKGROUND

At present, the research on the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is an important production raw material widely used. Based on the structural characteristics of lithium batteries, our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

TECHNOLOGICAL PROCESS

Shredder -- Hammer Crusher -- Grinder -- Separation Machine -- Pulse Dust Collector -- Classifying Screen -- Magnetic Machine -- Gravity Separator -- High-pressure Blower

ENVIRONMENTALLY FRIENDLY

Electric Car Traction Battery Lithium Ion Battery Recycling Machine adopts water spray facility and activated carbon device used to absorb odors and pulse dust collecter for dust adsorption.

TECHNICAL PARAMETERS

| Model | Capacity | Powder |

| LDC-300 | 300Kg/H | 55kw |

| LDC-500 | 500Kg/H | 82kw |

| LDC-1000 | 1000Kg/H |

107kw |

| WORKING PERFORMANCE | ||

| Raw Material | Lithium Battery | |

| Final Product | Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder | |

NOTE:

TECHNICAL STANDARDS

|

Feature Item

|

Indicator Requirments

|

|

Recovery Rate of Metallic Aluminum

|

>98%

|

|

Powder Recovery Rate

|

>98%

|

|

Content of Powder In Metal Aluminum

|

<2%

|

|

Content of Metallic Aluminum In Powder

|

<2%

|

|

Other

|

Contain dust collecter with not pollute

|

|

Qualified Rate

|

99%

|

|

Failure Rate

|

<1%

|

|

CMR

|

≥1.67

|

FAQ

1.Why Choose Us?

(2) Reliable quality: Use the best raw materials to ensure the machine works stably and efficiently for a long time.

(3) Professional team: From pre-sales to after-sales, we always provide you with the best service.

(4) Competitive price: Self-design and manufacturing, cost efficient.

2.What Is Our Service?

(2)You are welcome to visit our factory to test the machine. And we will customize the equipment strictly according to your special requirements and arrange the timely delivery.

(3)We will provide one year warranty for our machine.According to your need,we will dispatch our engineers to your factory to guide the installation,commissioning and training your workers.